Battery, and positive electrode plate and roll core thereof

A positive electrode sheet and electrode sheet technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, secondary batteries, and battery pack components, can solve problems such as limiting the use of lithium-ion batteries, unfavorable normal use of equipment, and heating on the surface of batteries. To achieve the effect of reducing internal resistance, reducing the rise, and reducing ohmic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

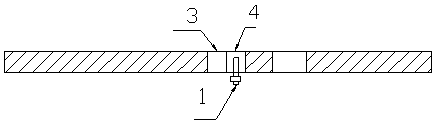

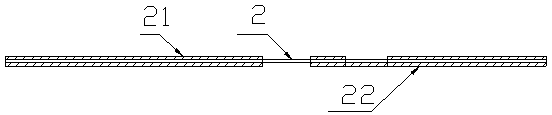

[0033] A positive electrode sheet of a battery, such as figure 1 and figure 2 As shown, it includes a pole piece 1 and a pole piece 2, the number of the pole piece 1 is one, the pole piece 1 is located in the middle of the pole piece, and the front side of the pole piece 2 is connected to the first active layer 21, so The back side of the pole sheet 2 is connected with the second active layer 22, the first 21 and the second active layer 22 are composed of positive electrode active materials, and the surface density of the positive electrode sheet is 160 ~ 220g / m 2 . There is a tab 1 on the positive electrode sheet, and a main installation position 3 and a sub-installation position 4 are arranged in the middle of the pole piece 2, the main installation position 3 and the sub-installation position 4 are adjacently arranged, and the tab 1 is installed in one of the main installation position 3 and the auxiliary installation position 4, and the pole piece 2 is not coated with a...

Embodiment 2

[0037] A positive electrode sheet of a battery, such as Figure 6 and 7 As shown, including the pole lug 1 and the pole piece 2, the number of the pole lug 1 is not less than one, and at least one of the not less than one pole lug 1 is located in the middle of the pole piece 2, the pole piece The front of the sheet 2 is connected to the first active layer 21, and the back of the pole sheet 2 is connected to the second active layer 22. The first 21 and the second active layer 22 are composed of positive electrode active materials, and the positive electrode sheet The surface density is 160~220g / m 2. The positive electrode sheet includes a plurality of tabs 1, the number of the tabs 1 is n, where n>1; the pole piece 2 is provided with n main mounting positions 3 and n secondary mounting positions 4 , wherein the i-th tab among the n tabs 1, 1≤i≤n; the i-th tab is installed in one of the i-th main installation position and the i-th sub-installation position, and the pole piece...

Embodiment 3

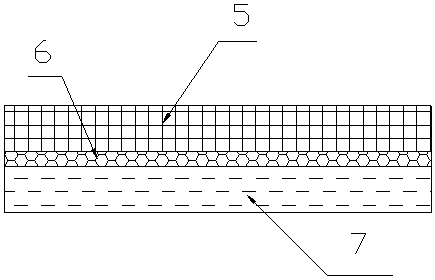

[0040] A battery core such as Figure 3~5 As shown, it includes the above-mentioned positive electrode sheet 5 , separator 6 and negative electrode sheet 7 , and the core 8 is composed of positive electrode sheet 5 , separator 6 and negative electrode sheet 7 , and the electrode sheet is wound. The thickness of the diaphragm 6 is 12-16 μm, the porosity of the diaphragm 6 is 35-55%, and the air permeability of the diaphragm 6 is 150-300s. The length of the negative electrode sheet of the winding core 8 is greater than the length of the positive electrode sheet. It also includes glue lines, which include a first glue line 91, a second glue line 92, and a third glue line 93, and the first glue line 91 and the second glue line 92 are wound on the core 8, the third closing glue line 93 perpendicularly intersects the first 91 and the second closing glue line 92; the third closing glue line 93 is arranged between the positive pole and the negative pole of the core 8, and the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com