Seat heating system

A seat heating and heating unit technology, which is applied to chairs, other seating furniture, stools, etc., can solve the problems of reduced temperature increase speed, high circuit implementation cost, and reduced heat generation efficiency, achieving fast heating and heating speed and wide application range Wide range and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

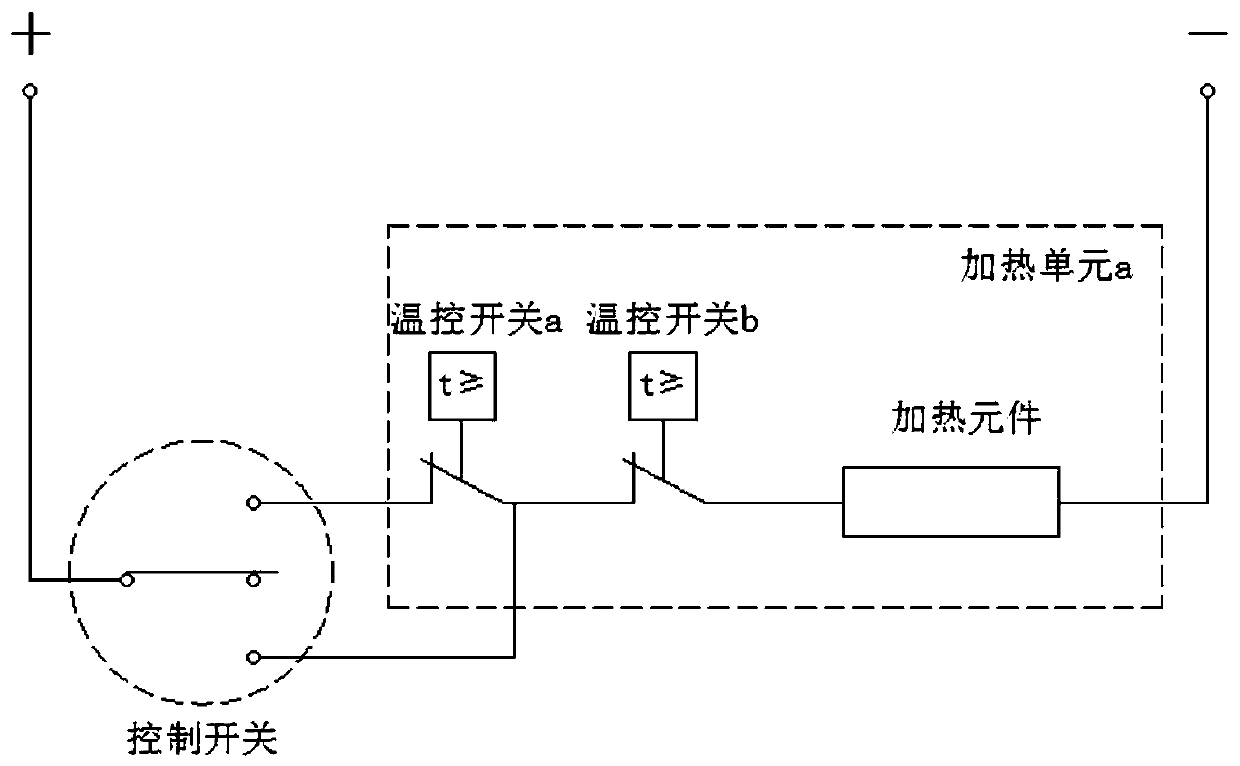

[0023] see figure 1 and figure 2 , a seat heating system, the heating system includes a heating module and a control switch:

[0024] The heating module includes a heating unit a and 0 heating units b. This structure is suitable for heating control of a heating element. The heating unit a includes a temperature control switch a, a temperature control switch b and a heating element. In the heating unit a The temperature control switch a, the temperature control switch b and the heating element are connected in series in sequence, and the disconnection temperature of the temperature control switch a is lower than that of the temperature control switch b; the temperature control switch a is normally closed, and the model is KSD9700-40 ℃ bimetallic temperature control switch, the temperature control switch b is a normally closed bimetallic temperature control switch with a model of KSD9700-60℃, and the heating element is carbon fiber heating wire;

[0025] The control switch is...

Embodiment 2

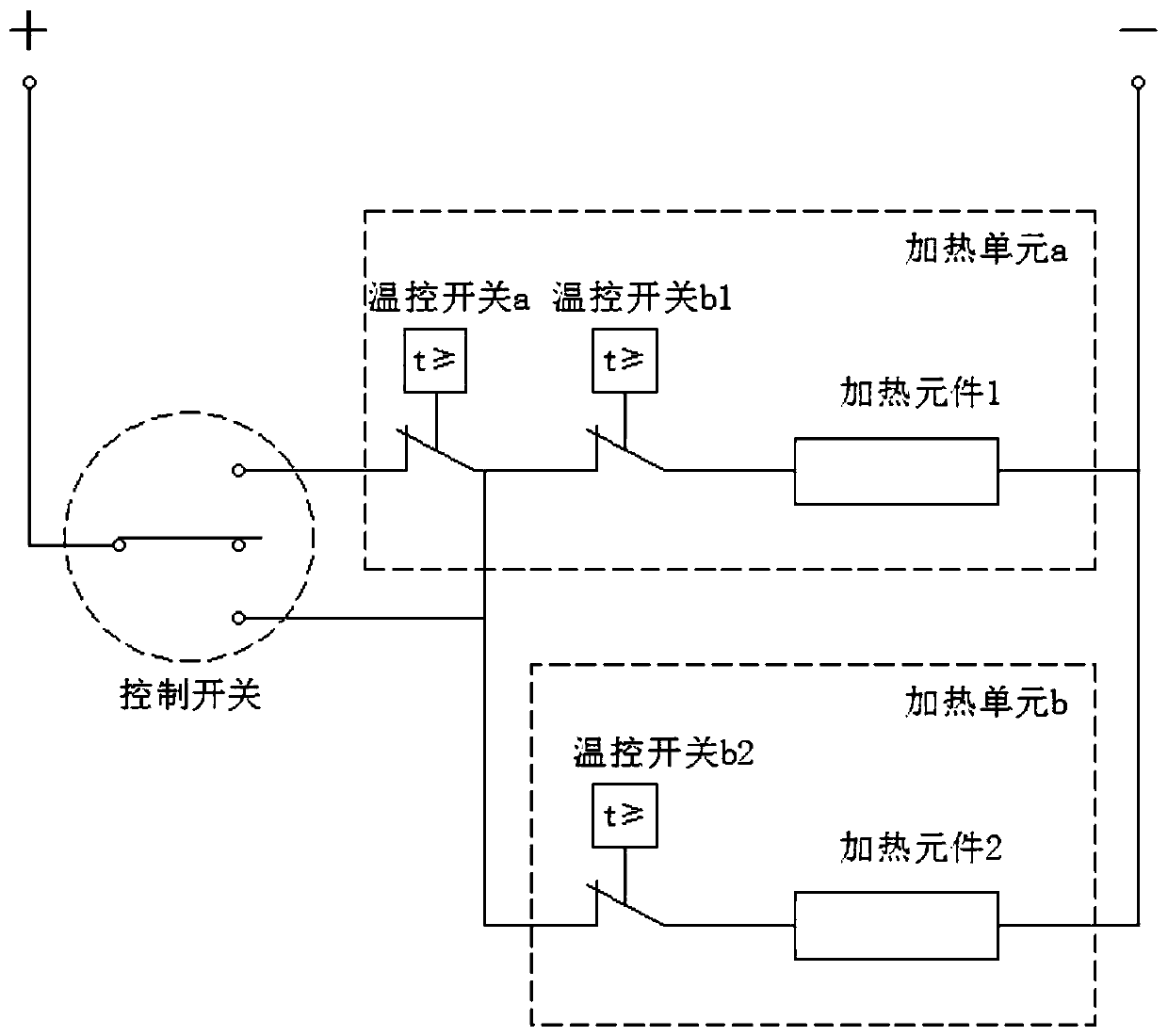

[0028] see figure 1 and image 3 , a seat heating system, the heating system includes a heating module and a control switch:

[0029] The heating module includes a heating unit a and a heating unit b. This structure is suitable for heating control of two heating elements. The heating unit a includes a temperature control switch a, a temperature control switch b1 and a heating element 1. The heating unit The temperature control switch a, temperature control switch b1 and heating element 1 in a are connected in series in sequence, and the disconnection temperature of the temperature control switch a is lower than that of the temperature control switch b1; the heating unit b includes a temperature control switch b2 and a heating element Element 2, and the temperature control switch b2 in the heating unit b is connected in series with the heating element 2 in sequence; the temperature control switch b1 in the heating unit a and the heating element 1 part and the heating unit b ar...

Embodiment 3

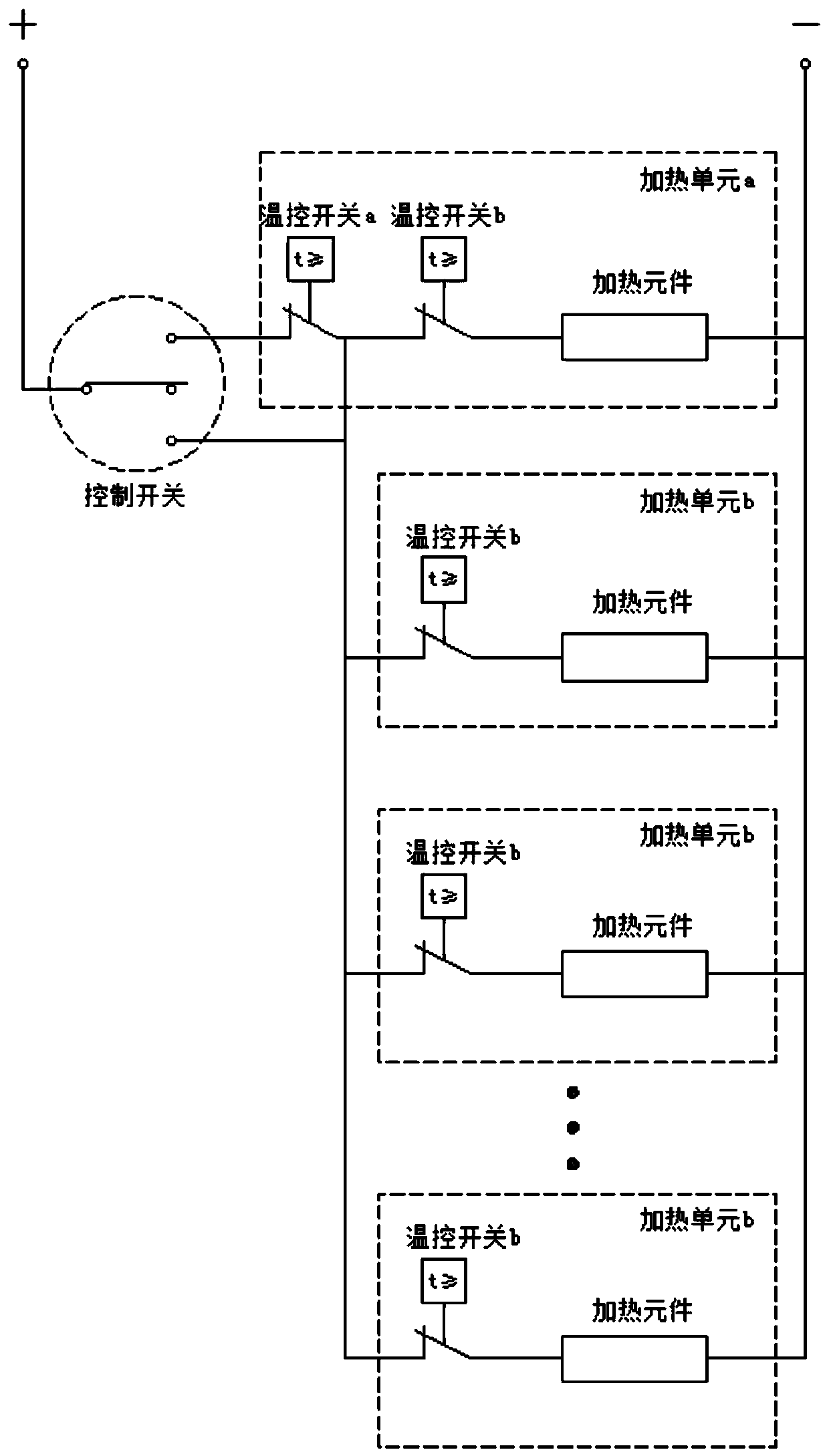

[0033] see figure 1 and Figure 4 , a seat heating system, the heating system includes a heating module and a control switch:

[0034] The heating module includes one heating unit a and two heating units b. This structure is suitable for heating control of three heating elements. The heating unit a includes a temperature control switch a, a temperature control switch b1 and a heating element 1. The heating unit The temperature control switch a, temperature control switch b1 and heating element 1 in a are connected in series in sequence, and the disconnection temperature of the temperature control switch a is lower than that of the temperature control switch b1; the heating unit b1 includes a temperature control switch b2 and a heating element element 2, and the temperature control switch b2 in the heating unit b1 and the heating element 2 are connected in series; the heating unit b2 includes a temperature control switch b3 and a heating element 3, and the temperature control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com