Pneumatic closed door oven

A closed door, air pressure technology, applied in the field of ovens, can solve problems such as affecting the baking process, uneven baking, and easy damage to the outer surface of the oven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

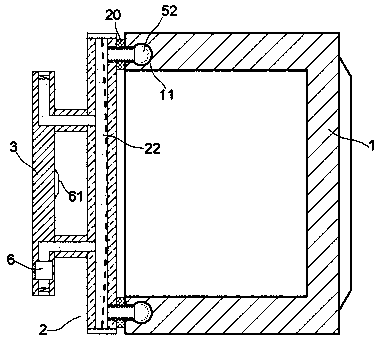

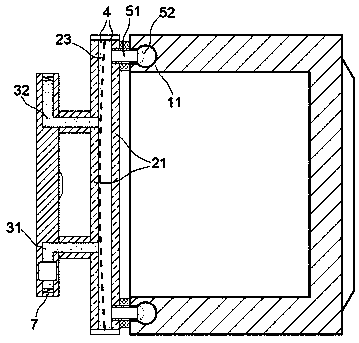

[0018] exist figure 1 , figure 2 In the shown embodiment, the air pressure closed door oven includes a box body 1, a door body 2 and a handle 3, and the door body 2 is reversibly connected to the door body 2; A sealing ring 20 made of elastic material is provided at the position of the frame of the box body 1; locking teeth are arranged on the door body 2, and a lock tooth is provided on the frame of the box body 1 facing the door body 2; Locking groove 11 matching tight teeth;

[0019] Described door body 2 comprises two closing plates 21 and surrounding edges that are arranged in parallel, adjacent closing plates 21 and surrounding edges form closed chamber 22; Made of memory metal, the isolation plate 23 protrudes toward the inside of the box body 1 at high temperature, and protrudes toward the outside of the box body 1 at low temperature; the isolation plate 23 divides the closed cavity 22 into two independent cavities Room 4;

[0020] The locking tooth includes a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com