Machining method of aviation parts spinning blanks

A technology for machining and parts, applied in the field of machining of blanks of spinning parts for aerospace parts, can solve the problems of uneven blank allowance and low processing efficiency of spinning parts, so as to reduce the degree of human intervention and improve processing efficiency. , The effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

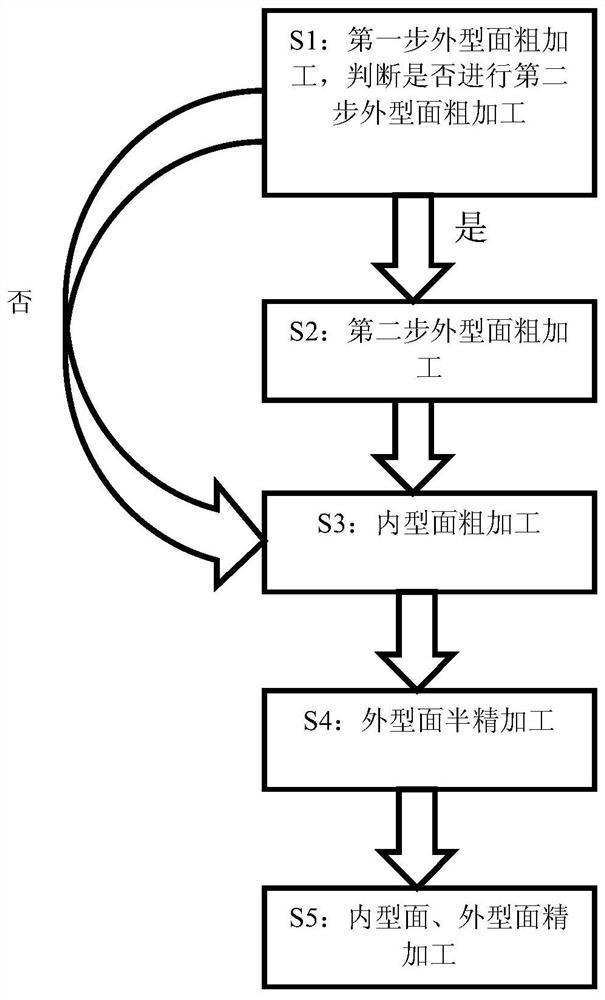

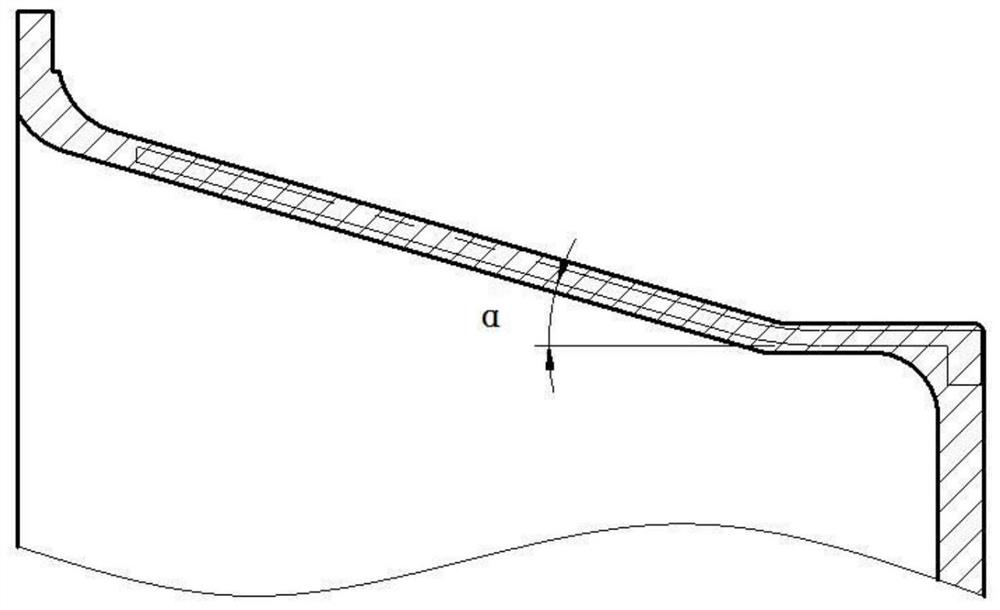

[0058]Take the processing of a certain type of engine combustion chamber casing as an example. The engine combustion chamber casing is a typical spinning part, such asfigure 2 As shown, the known surface taper α=16°.

[0059]According to the theoretical dimensions of the parts of the combustion chamber casing and the theoretical dimensions of the parts, the theoretical unilateral allowance A of the inner and outer surface of the part is calculated to be 3mm, and the remaining finishing allowance is 0.15mm. The processing steps are as follows:

[0060]S1. After aligning and clamping the parts, perform the first rough machining on the outer surface to remove the rough machining allowance LCrude =2mm;

[0061]And judge whether the part continues to perform the second step of rough machining of the outer surface:

[0062](1) If all the outer surface is processed in place, then according to the theoretical unilateral allowance, skip to the third step to process down, and there is no need to advance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com