Automatic anti-running device for mine car

A braking device, automatic technology, applied in the direction of braking transmission, mine car, automatic brake, etc., can solve the problems of endangering safe production, time-consuming and laborious, poor braking performance, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

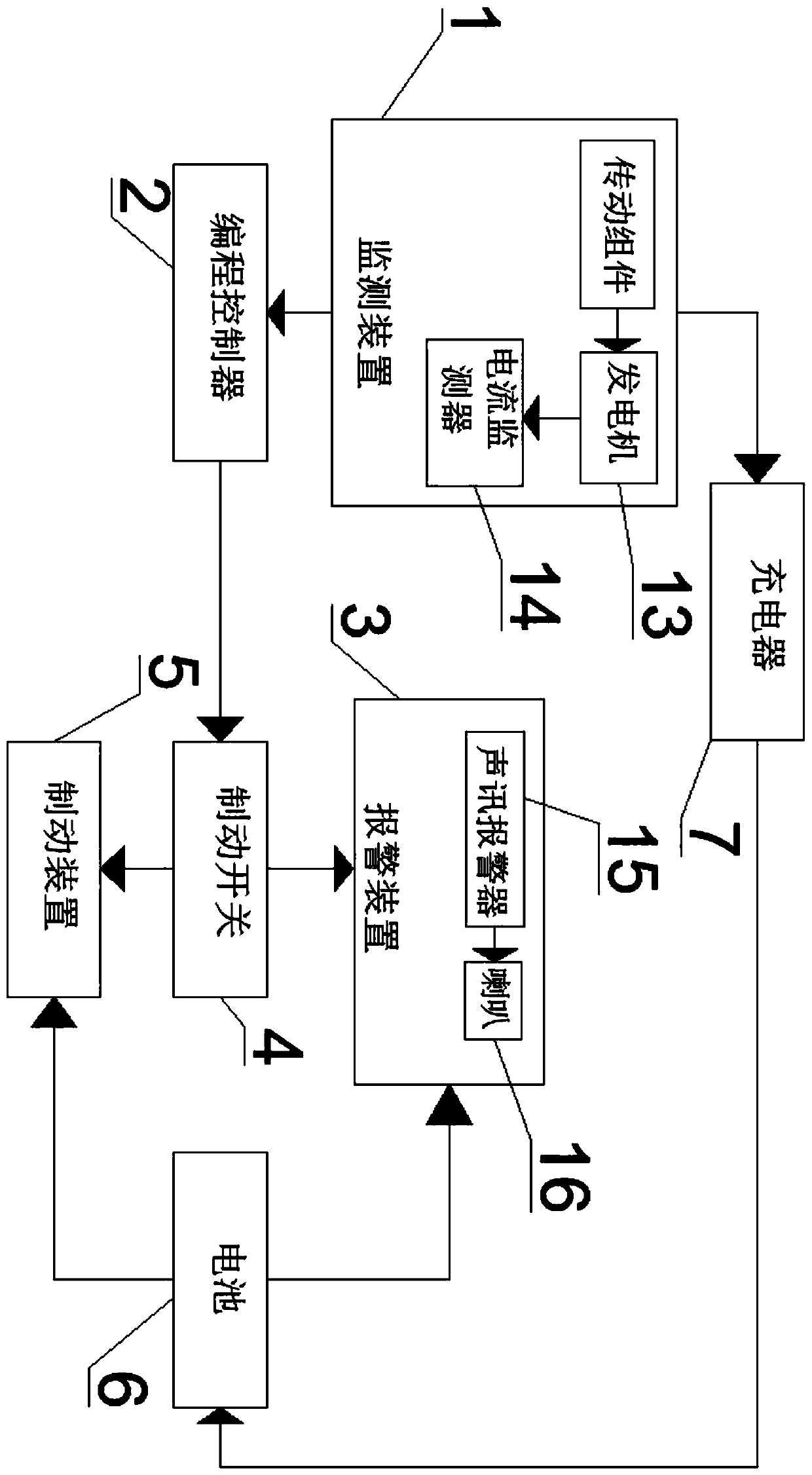

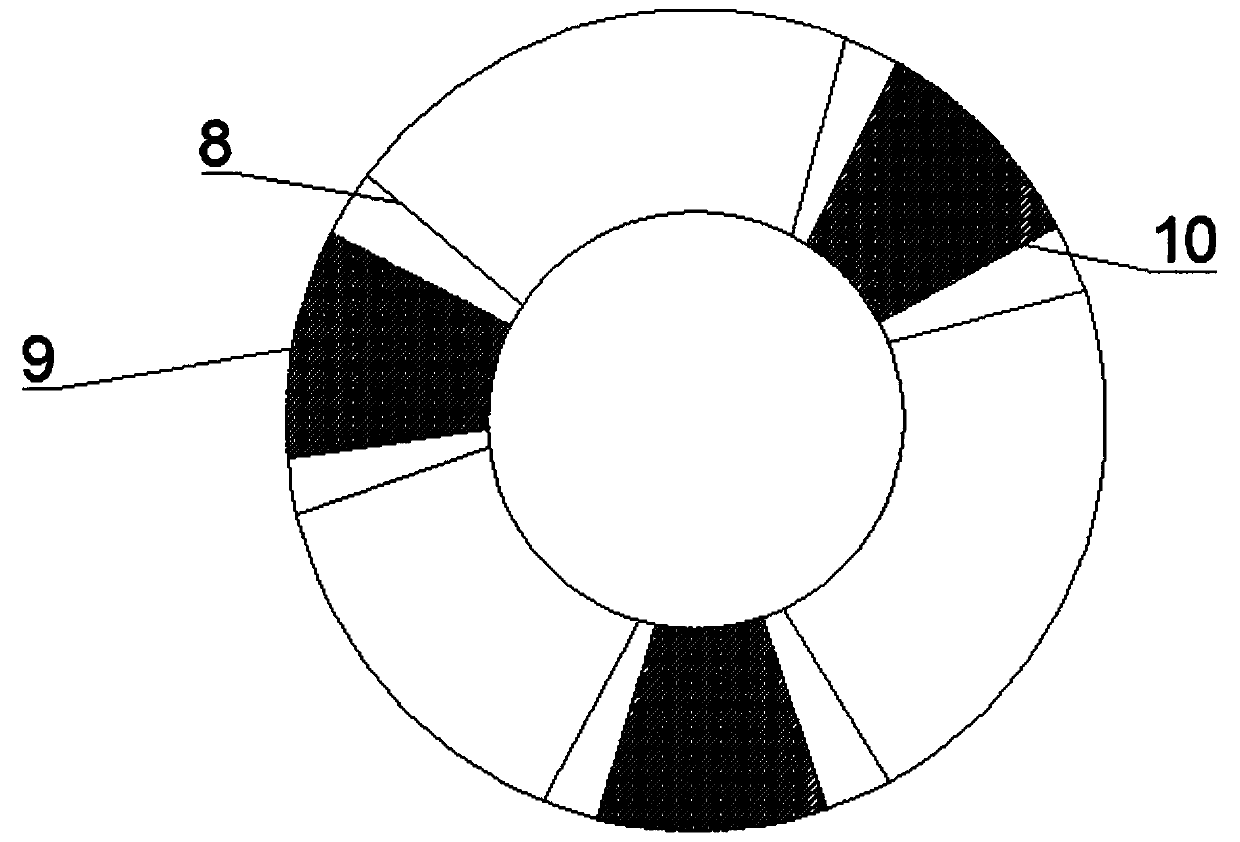

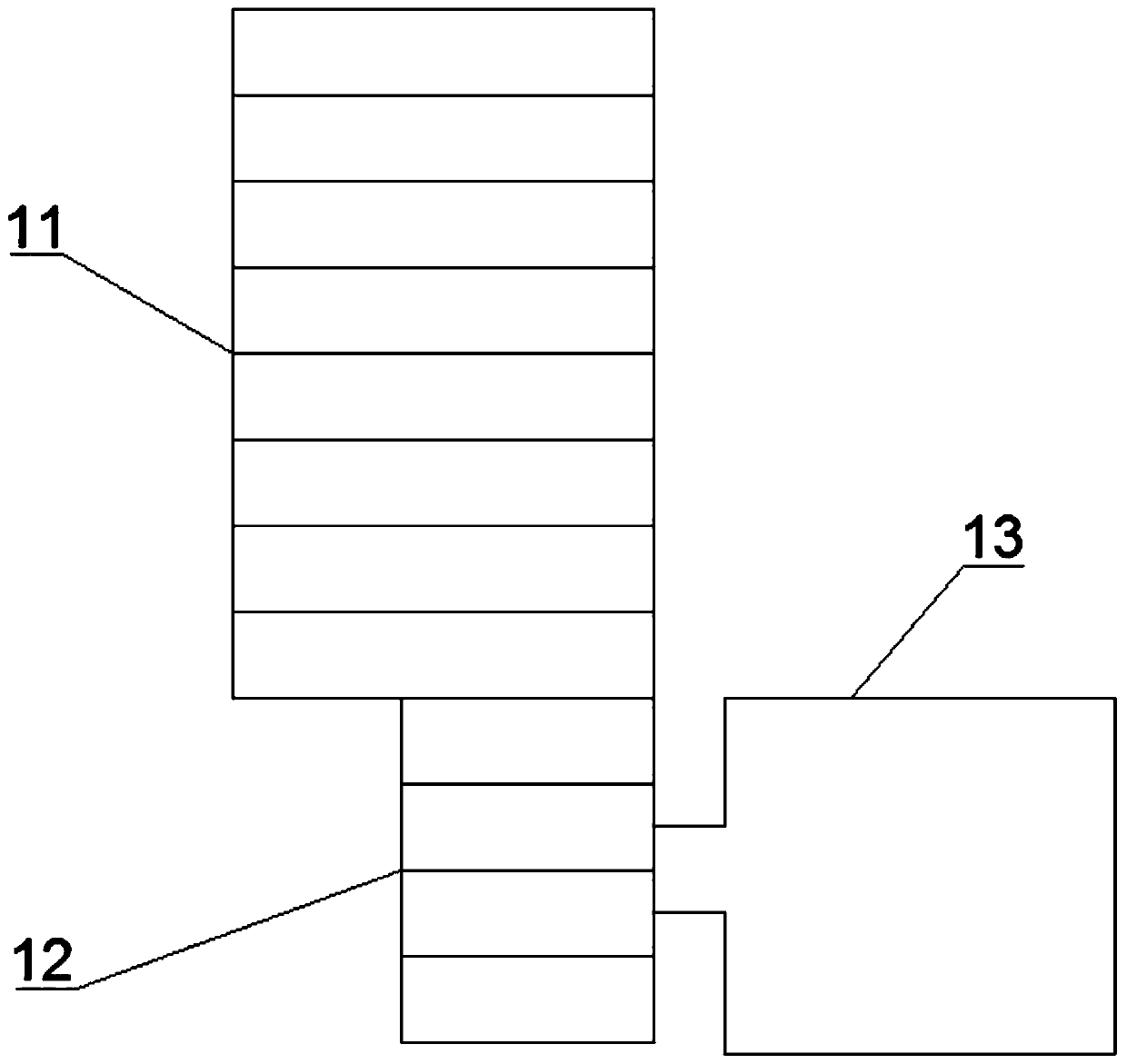

[0018] Such as figure 1 and image 3 As shown, a mine car automatic anti-running device includes a monitoring device 1, a brake switch 4, an alarm device 3 and a brake device 5, and the brake switch 4 is connected with a programming controller 2 through a control circuit. The automatic switch 4 is electrically connected with the alarm device 3 and the brake device 5. When the monitoring device 11 detects that the current exceeds the set value, the programming controller 2 will close the brake switch 4 to start The alarm device 3 and the braking device 5, the braking device includes an electromagnet 9, the electromagnet 9 is installed in the groove 8 between the wheel core and the hub of the wheel, and the electromagnet 9 inputs terminal is electrically connected to the output end of the battery 6, specifically, the N po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com