Locomotive brake control system and method

A brake control and locomotive technology, applied in the direction of brake safety systems, brakes, brake components, etc., can solve the problem that the train pipe pressure cannot be controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

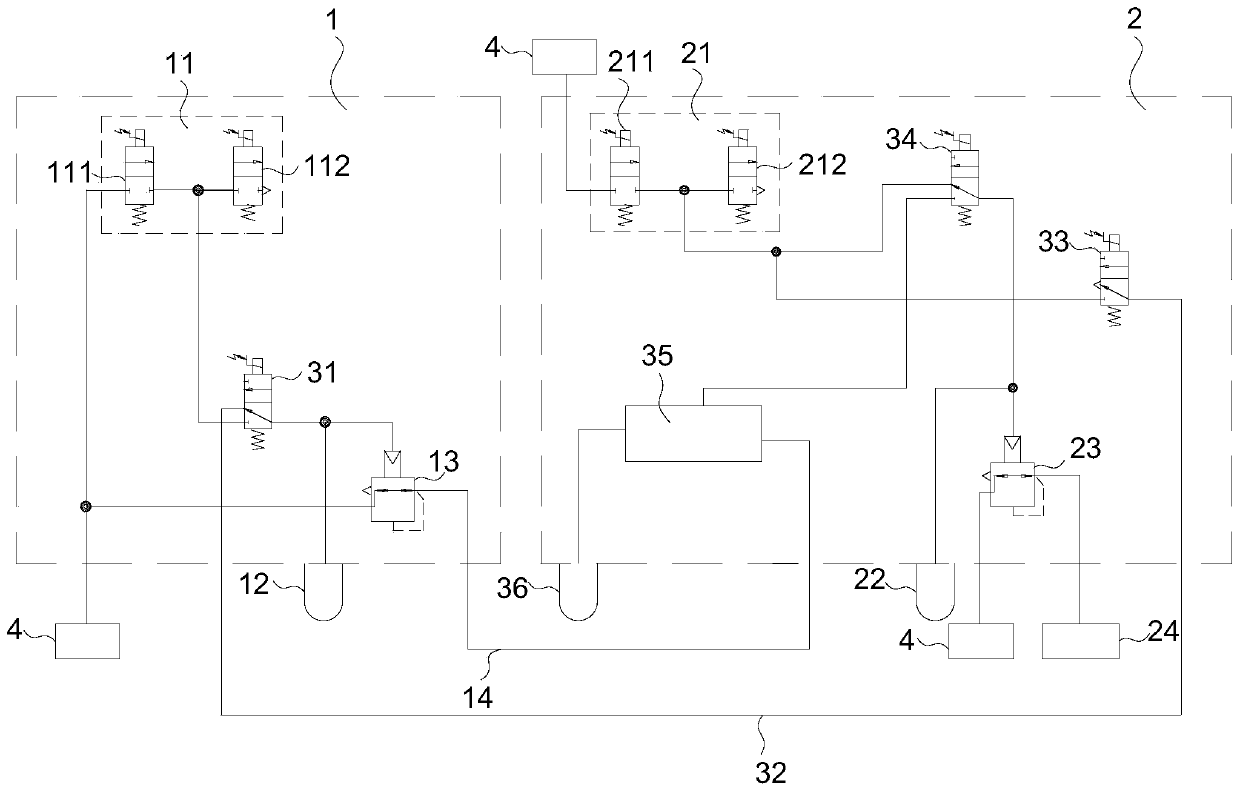

[0036] A locomotive brake control system, comprising a train pipe brake control module 1 and a brake cylinder brake control module 2, the train pipe brake control module 1 includes a first pressure control valve 11, an equalizing air cylinder 12, a first The relay valve 13 and the train pipe 14; the brake cylinder brake control module 2 includes the second pressure control valve 21, the pre-control air cylinder 22, the second relay valve 23 and the brake cylinder 24 connected in sequence; also includes the train The tube redundant brake control module, the train tube redundant brake module is connected between the equalizing air cylinder 12 and the second pressure control valve 21 and the pre-control air cylinder 22 .

[0037] The locomotive braking control system provided in the first embodiment is provided with a train management redundant braking control module, and the train management redundant braking control module is connected between the train management braking contro...

no. 2 example

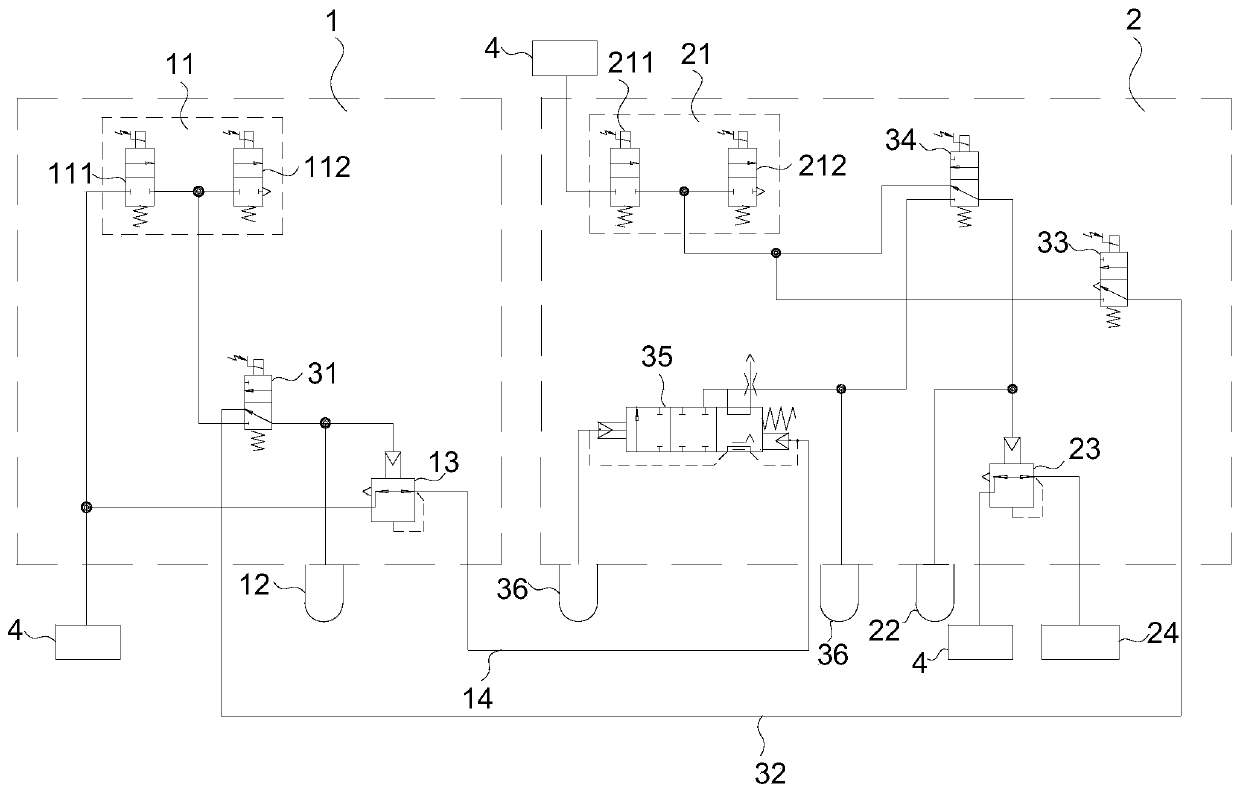

[0057]The present invention also provides a second embodiment. In the second embodiment, a distribution valve is used as the mechanical distribution valve 35. For the specific structure of the distribution valve, please refer to CN2017104076361. There are two working air cylinders 36, and the two working air cylinders 36 are connected with distribution valves.

[0058] All the other parts are the same as the first embodiment.

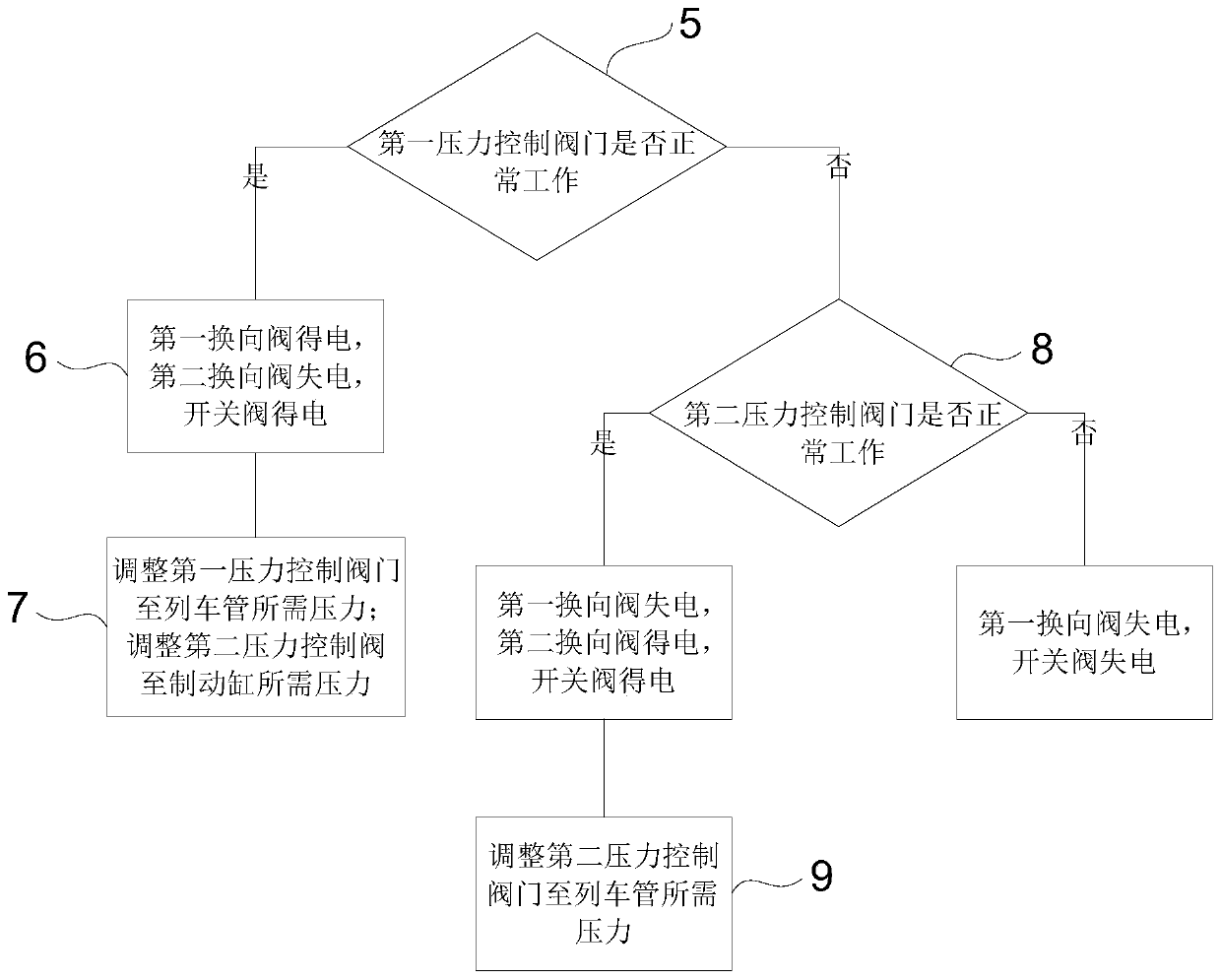

[0059] An embodiment of the present invention also provides a locomotive braking control method, using the above-mentioned locomotive braking control system, including the following steps:

[0060] Step 1: Detect whether the first pressure control valve 11 works normally; if it works normally, go to step 2; if not, go to step 4;

[0061] Step 2: Disconnect the channel connection between the redundant brake control module of the train pipe and the equalizing air cylinder 12, and connect the first pressure control valve 11 with the equalizing air cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com