Polymer plastic film device

A plastic film and polymer technology, applied in the field of film processing, can solve the problems affecting the qualified rate of plastic film products, poor plastic film effect, and economic loss of enterprises, and achieve simple structure, remove or reduce wrinkles, and reduce economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

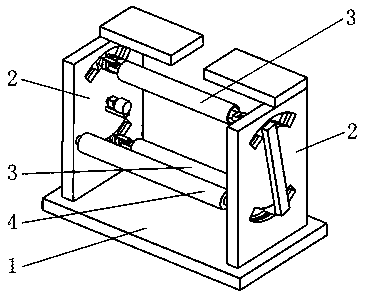

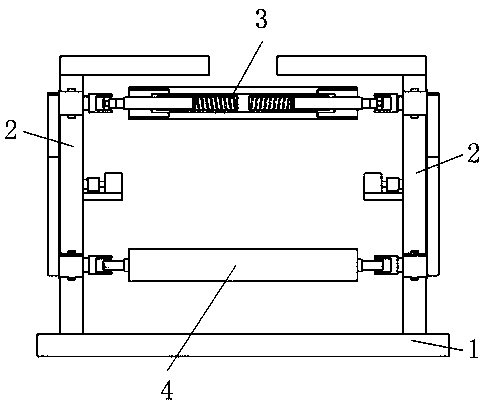

[0030] Such as figure 1 As shown, it includes a base 1, an adaptive mechanism 2, a roller mechanism 3, a first roller 4, and a first roller shaft 5, wherein as figure 1 , 2 As shown, a first roller shaft 5 and two roller mechanisms 3 are installed between the two adaptive mechanisms 2 symmetrically installed on both sides of the base 1 , and the first roller shaft 5 is nested with the first roller 4 .

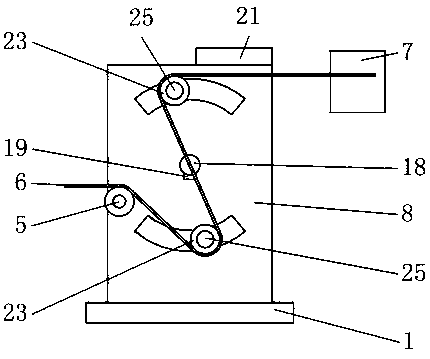

[0031] Such as Figure 4 , 5 As shown, the above-mentioned adaptive mechanism 2 includes a support plate 8 installed on the base 1, an arc slider 13, a pendulum plate 15, a pendulum shaft 16, a shaft coupling 17, an angular displacement sensor 18, a scroll spring 20, a hot air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com