Film slitting efficient slitting machine with blade conveniently replaced

A film slitting, high-efficiency technology, applied in the direction of thin material processing, sending objects, transportation and packaging, etc., can solve the problem of reducing the feeding rate of the slitting machine, the total weight of the support shaft and the film, and reducing the maintenance of the slitting machine. It can improve the speed of feeding, improve convenience and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

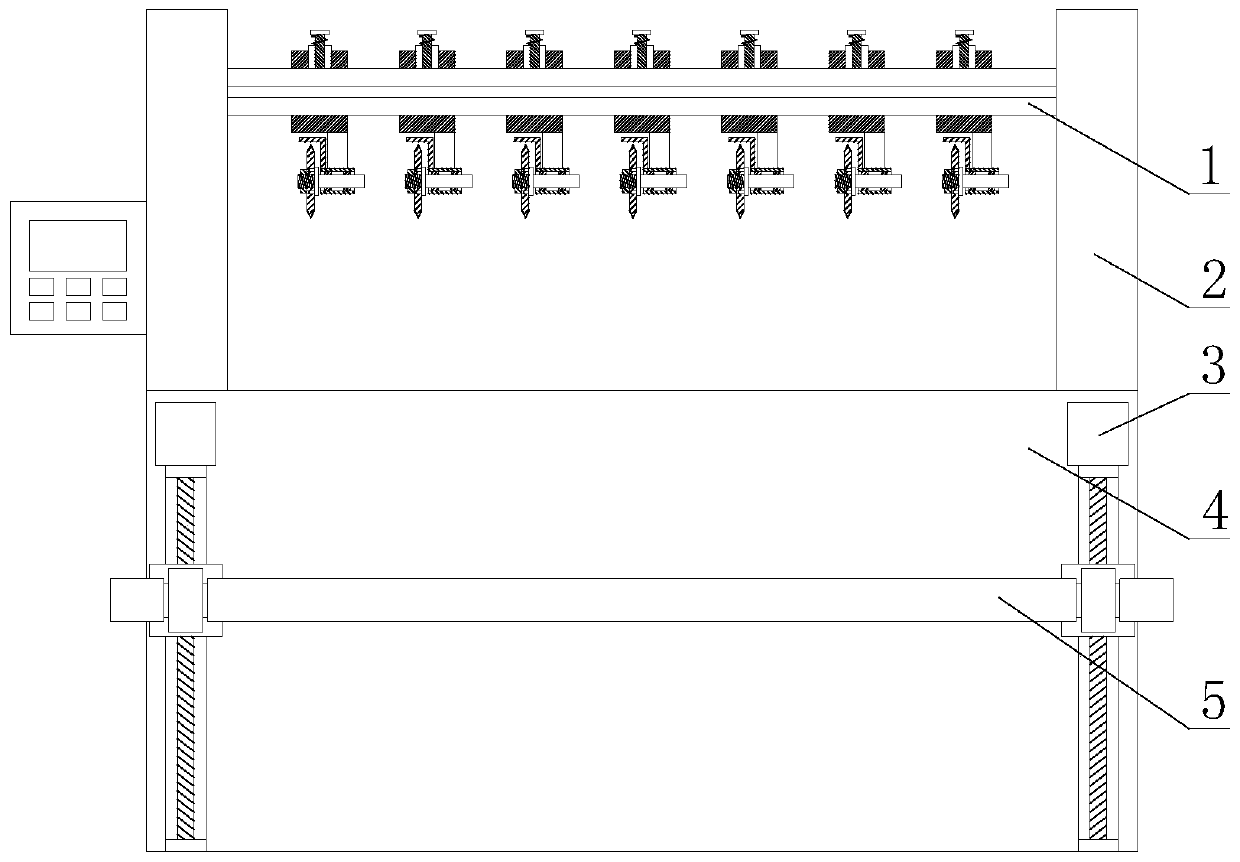

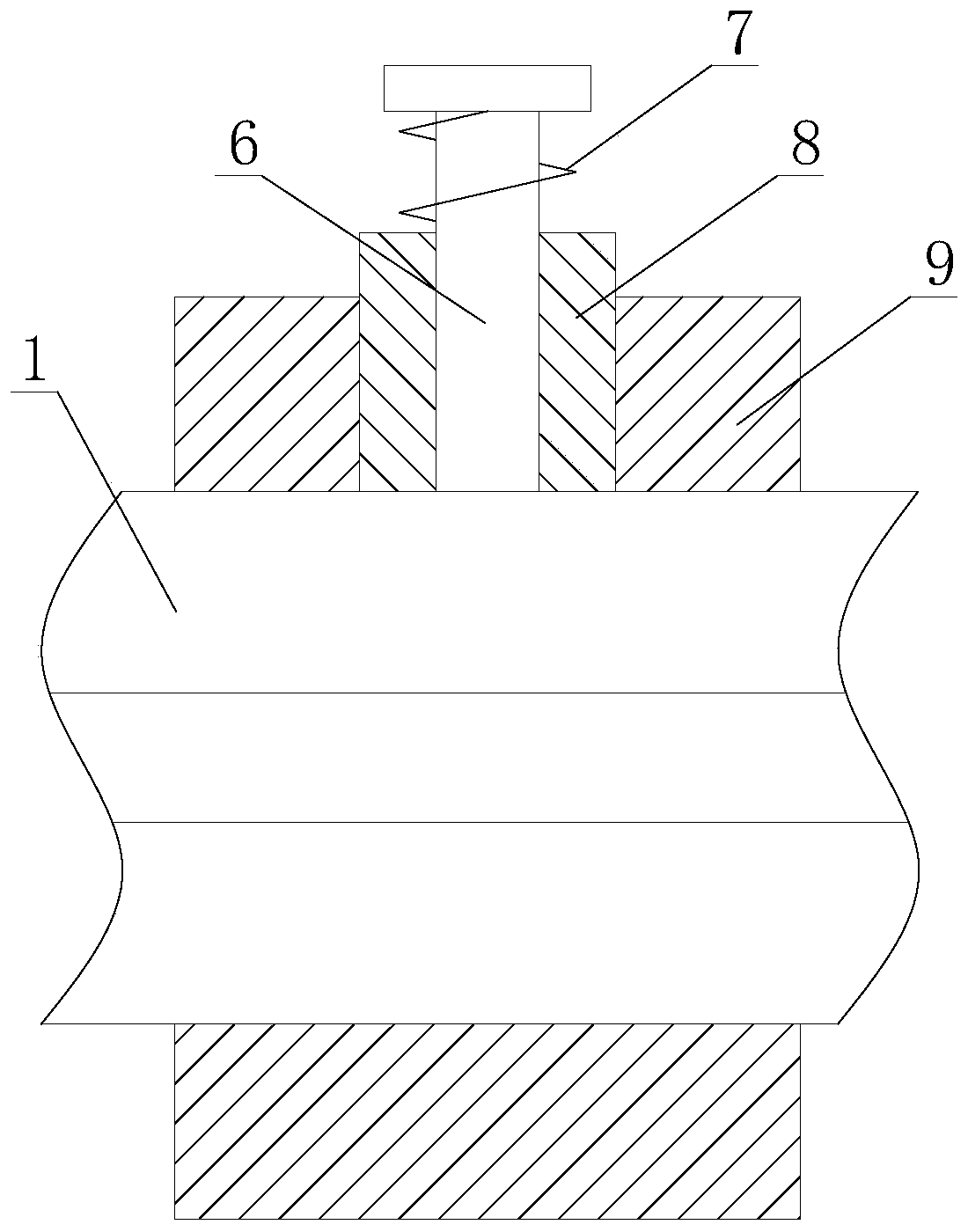

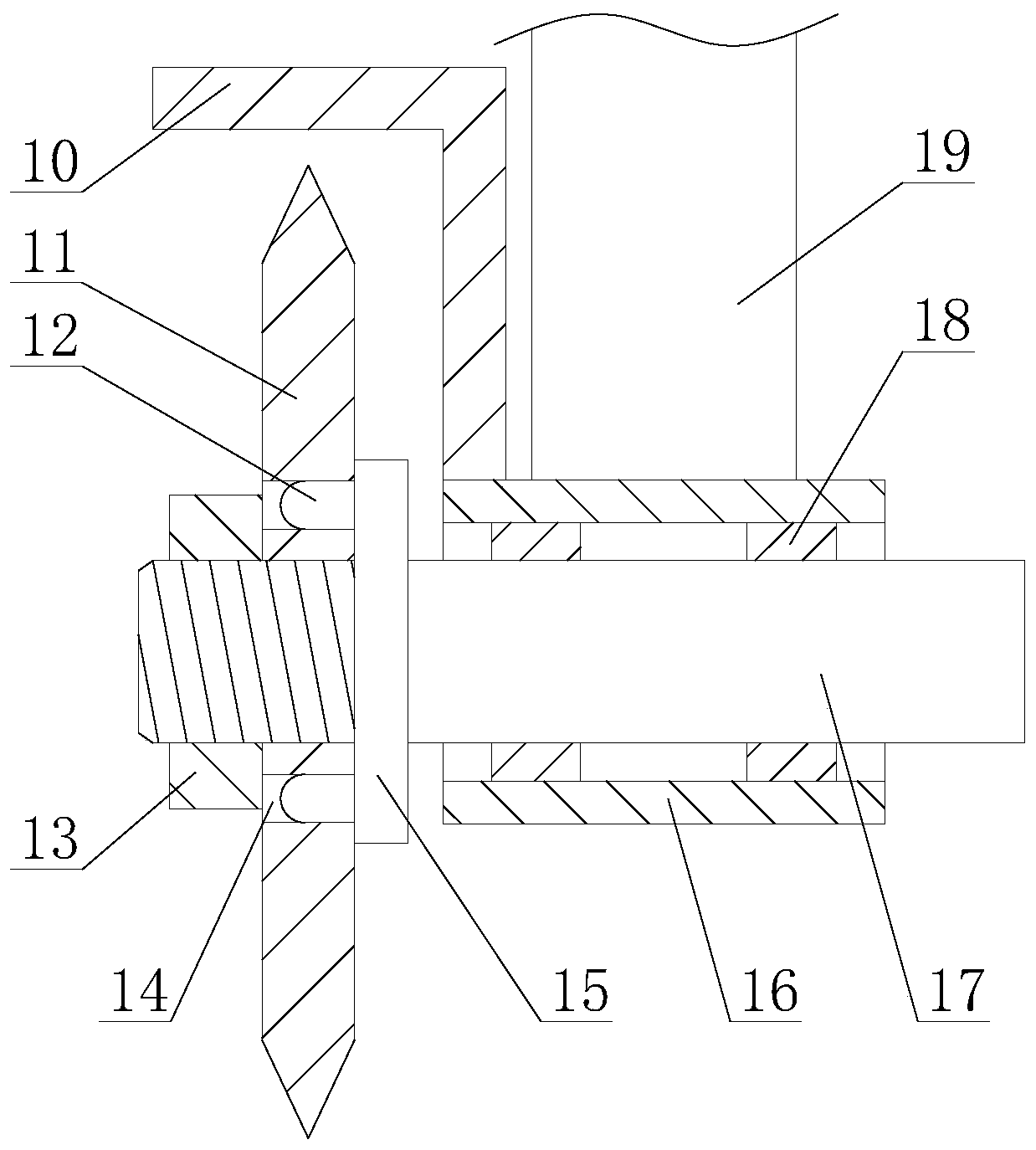

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0027] Such as figure 1 As shown, a high-efficiency slitting machine that is convenient for blade replacement for film slitting includes a base 4, a guide rail 1 and two supports 2, and the support 2 is arranged on one side of one end of the base 4, and the guide rail 1 is perpendicular to the bracket 2, one end of the guide rail 1 is fixedly connected to the bracket 2, and also includes a feeding mechanism and at least two cutting mechanisms, the feeding mechanism is arranged on one side of the base 4, and each cutting mechanism is arranged in a row on rail 1;

[0028] The convenience of film raw material feeding is improved by the feeding mechanism, the sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap