Adhesive tape device

A tape and adhesive layer technology, applied in adhesives, transportation and packaging, inorganic chemistry, etc., can solve problems such as narrow temperature range, loss of viscosity, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

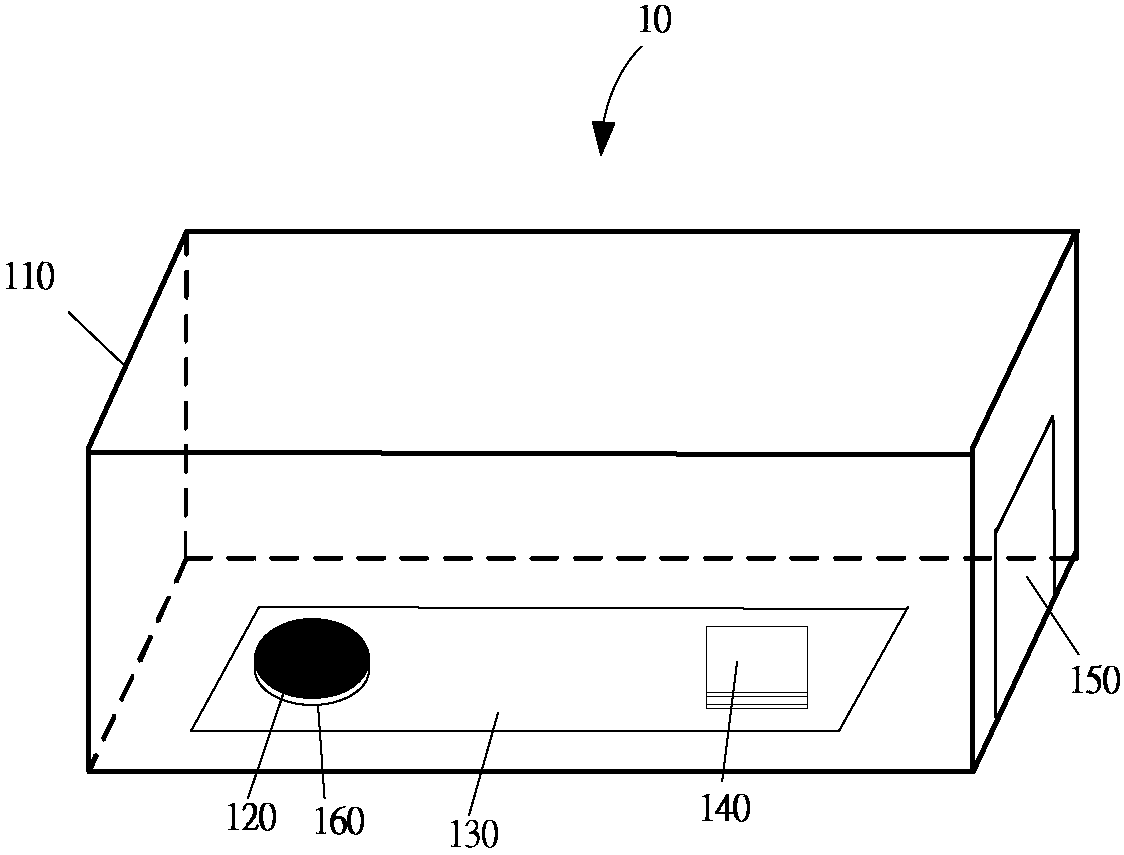

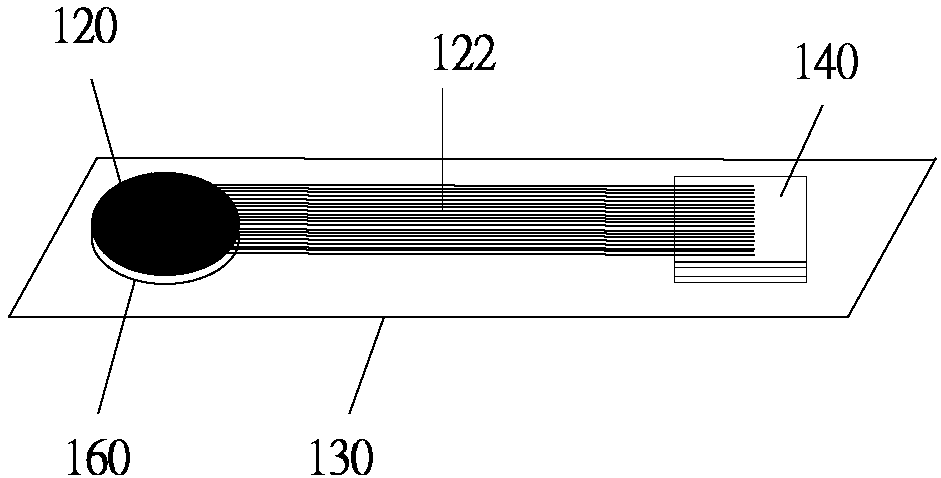

[0035] The preparation method of the super-aligned carbon nanotube array 120 is not limited, and may be a chemical vapor deposition method, an arc discharge preparation method, or an aerosol preparation method. In this embodiment, the preparation method of the super-aligned carbon nanotube array 120 adopts a chemical vapor deposition method, which is directly grown on the substrate 160, and the specific steps include: (a) providing the substrate 160; (b) on the substrate A catalyst layer is uniformly formed on the surface, and the material of the catalyst layer can be selected from one of the alloys of iron (Fe), cobalt (Co), nickel (Ni) or any combination thereof; (c) the above-mentioned substrate with the catalyst layer is formed at 700~ Annealing in air at 900°C for about 30 to 90 minutes; (d) placing the treated substrate in a reaction furnace, heating to 500-740°C under a protective gas environment, and then introducing a carbon source gas to react for about 5-30 Within m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com