A kind of poss/pa6 composite material and preparation method thereof

A composite material and phenyl technology, applied in the direction of silicon organic compounds, etc., can solve the problems affecting the improvement of mechanical properties such as low-temperature impact toughness of modified PA6, affecting the dispersion of POSS monomers, and the limited amount of POSS added, so as to improve the application temperature Range, low thermal conductivity, effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

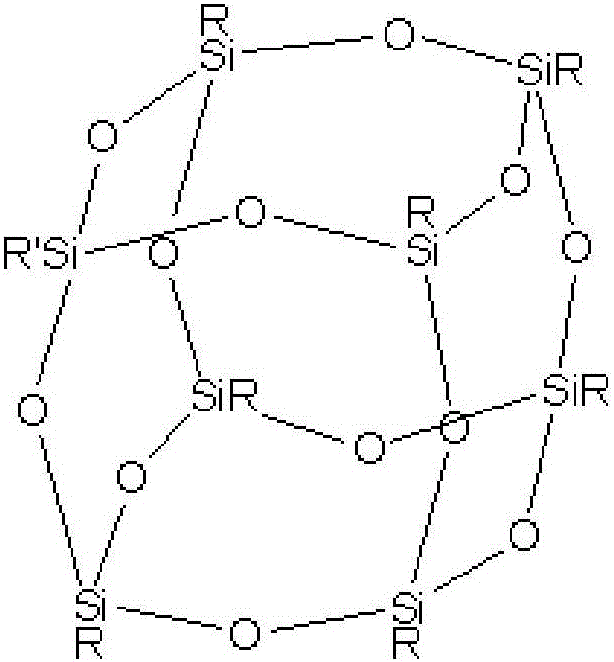

[0052] (1) 70ml of γ-(2,3-epoxypropoxy)propyltrimethoxysilane and 10ml of phenyltrimethoxysilane are added to a 250ml single-necked flask, then 150ml of ethanol is added thereto, and then Concentrated hydrochloric acid was added dropwise to the aforementioned mixed solution to adjust the pH value to about 3, and the temperature was raised to 90°C to react for 7 days; after the reaction was completed, it was filtered and vacuum-dried at 80°C for 24 hours to obtain the POSS product with the structure of formula (1);

[0053] (2) Dry the PA6 at 100°C for 3 hours;

[0054] (3) Weigh 99 parts of PA6 dried in (2) and 1 part of POSS prepared in (1), 0.2 parts of tetraerythritol ester antioxidant, 0.2 parts of phosphite tris(2,4-di-tert-butylphenyl) Ester antioxidant, 0.5 part of montan wax, mixed in a high-speed mixer for 5 minutes;

[0055] (4) Extrude and granulate the uniformly mixed material in a twin-screw extruder to obtain a POSS / PA6 composite material; the temperature of the...

Embodiment 2

[0057] (1) 70ml of γ-(2,3-epoxypropoxy)propyltrimethoxysilane and 10ml of cyclopentyltrimethoxysilane are added to a 250ml single-necked flask, and then 150ml of methanol is added thereto, Then, concentrated hydrochloric acid was added dropwise to the aforementioned mixed solution to adjust the pH value to about 3, and the temperature was raised to 90° C. to react for 7 days; after the reaction was completed, it was filtered and vacuum-dried at 80° C. for 24 hours to obtain the POSS product with the structure of formula (1);

[0058] (2) Dry the PA6 at 150°C for 4 hours;

[0059] (3) Weigh 95 parts of PA6 dried in (2) and 5 parts of POSS prepared in (1), 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphite antioxidant, 0.5 parts of pentaerythritol hard Fatty acid ester, 0.5 white wax oil, mixed in a high-speed mixer for 5 minutes;

[0060] (4) Extrude and granulate the uniformly mixed materials in a twin-screw extruder to obtain POSS / PA6 composite materials; the temperature o...

Embodiment 3

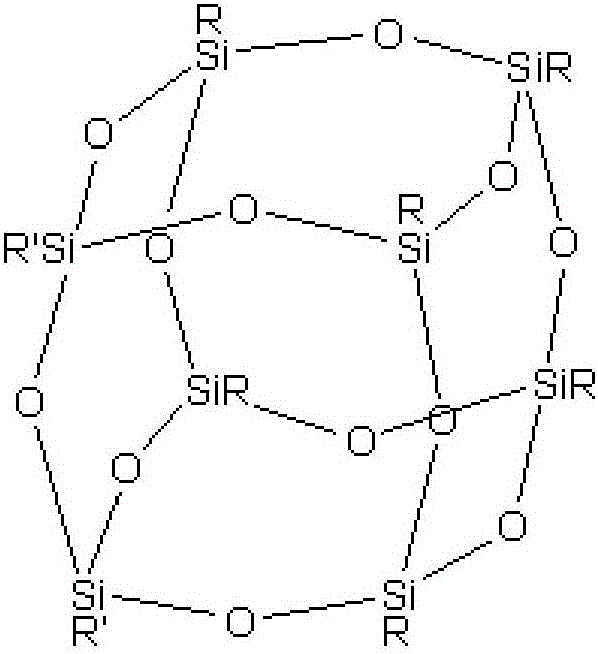

[0062] (1) 60ml of γ-(2,3-epoxypropoxy)propyltrimethoxysilane and 20ml of phenyltrimethoxysilane are added to a 250ml single-necked flask, then 150ml of ethanol is added thereto, and then Concentrated hydrochloric acid was added dropwise to the aforementioned mixed solution to adjust the pH value to about 3, and the temperature was raised to 90°C to react for 7 days; after the reaction was completed, it was filtered and vacuum-dried at 80°C for 24 hours to obtain the POSS product of formula (2).

[0063] (2) Dry the PA6 at 100°C for 3 hours;

[0064] (3) Weigh 90 parts of PA6 dried in (2) and 10 parts of POSS, 0.2 parts of phosphite tris (2,4-di-tert-butylphenyl) antioxidant, 0.2 parts of N prepared in (1), N'-hexamethylene bis(3,5-di-tert-butyl-4-hydroxyphenylpropionamide) antioxidant, 0.5 part of montan wax, mixed in a high-speed mixer for 5 minutes;

[0065] (4) Extrude and granulate the uniformly mixed materials in a twin-screw extruder to obtain POSS / PA6 composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com