A kind of lubricating grease composition and preparation method thereof

A technology of grease composition and cross-linking method, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as poor viscosity-temperature performance, achieve excellent viscosity-temperature performance, improve wear resistance, and not easily change color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

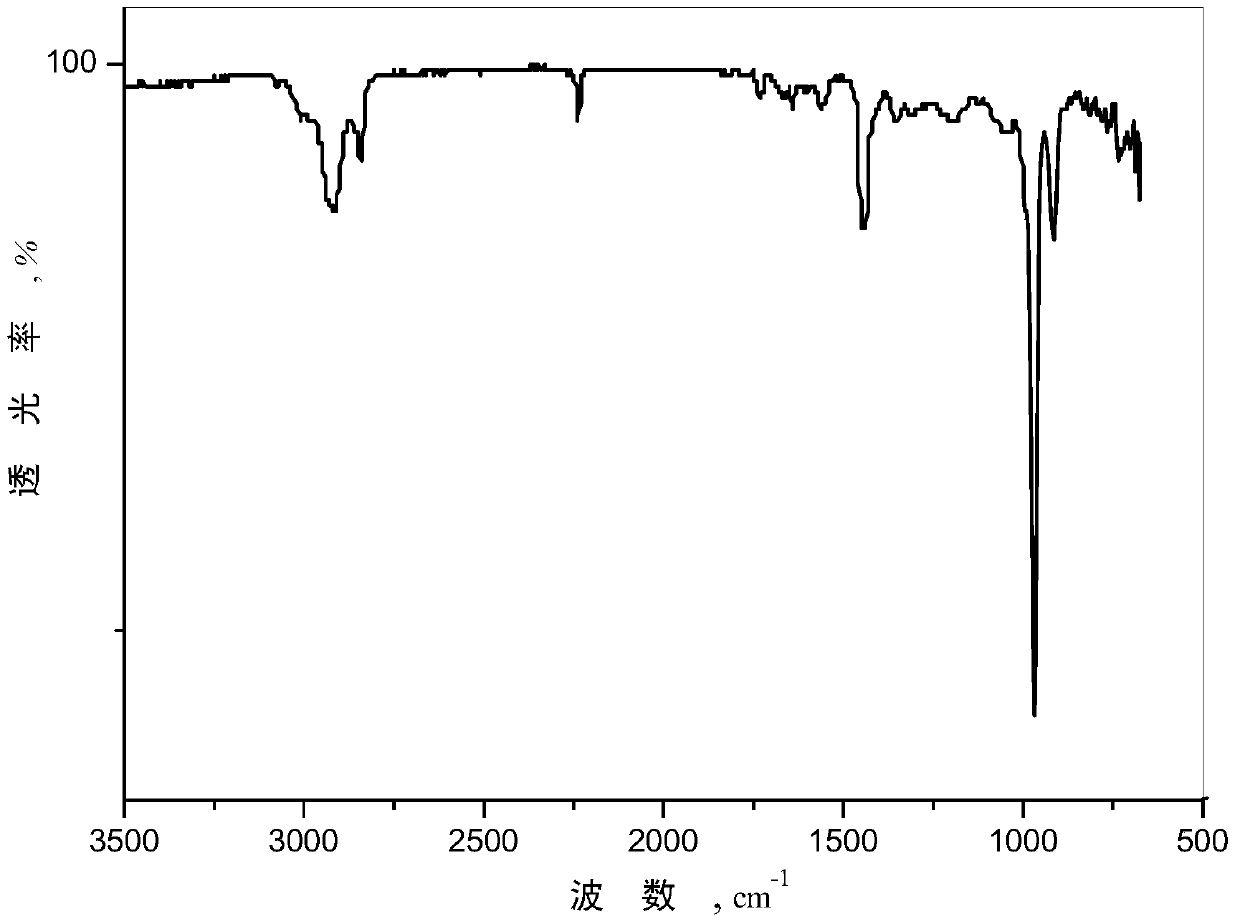

Image

Examples

preparation example Construction

[0028] The preparation method of the lubricating grease composition provided by the present invention comprises mixing and dispersing base oil and nitrile rubber particles to be dispersed with a crosslinked structure prepared by a radiation crosslinking method, and relative to 100 parts by weight of the base oil, the amount of the nitrile rubber particles to be dispersed is 10-180 parts by weight.

[0029] According to the preparation method of the grease composition provided by the present invention, as mentioned above, relative to 100 parts by weight of the base oil, the amount of the nitrile rubber particles to be dispersed is 10-180 parts by weight, but in order to make the base oil Play a better synergistic effect with the nitrile rubber particles to be dispersed, and then make the resulting grease composition have better viscosity-temperature properties, preferably, relative to the base oil of 100 parts by weight, the to-be The amount of dispersed nitrile rubber particle...

Embodiment approach

[0039] The present invention is not particularly limited to the manner of mixing and redispersing, as long as the nitrile rubber particles to be dispersed can be effectively dispersed in the base oil, thereby obtaining a mixture with the base oil as the continuous phase and the nitrile rubber particles as the dispersed phase. phase grease composition. According to a preferred embodiment of the present invention, the mixing and dispersing mode includes:

[0040] (1) adding the nitrile rubber particles to be dispersed in the base oil and mixing by mechanical stirring, so that the nitrile rubber particles to be dispersed are dispersed or suspended in the base oil to obtain a preliminary dispersed composition;

[0041] (2) redispersing the composition of the preliminary dispersion until the average particle diameter of the dispersed nitrile rubber particles reaches in the range of 20-2000nm, preferably in the range of 50-1000nm, more preferably in the range of 70-500nm In the ran...

Embodiment 1

[0058] This example is used to illustrate the grease composition provided by the present invention and its preparation method.

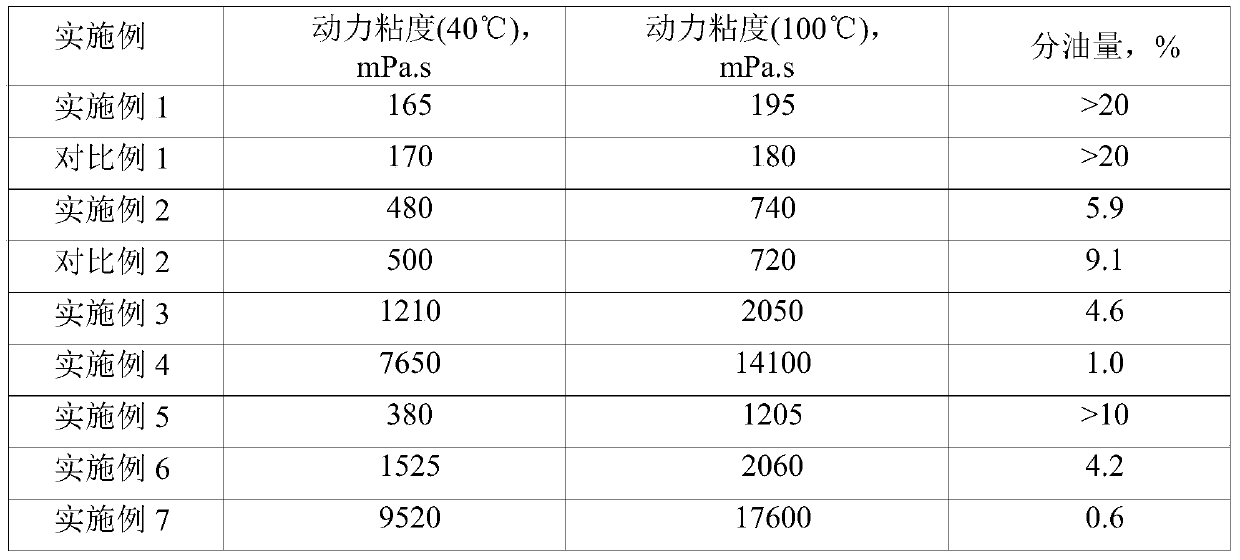

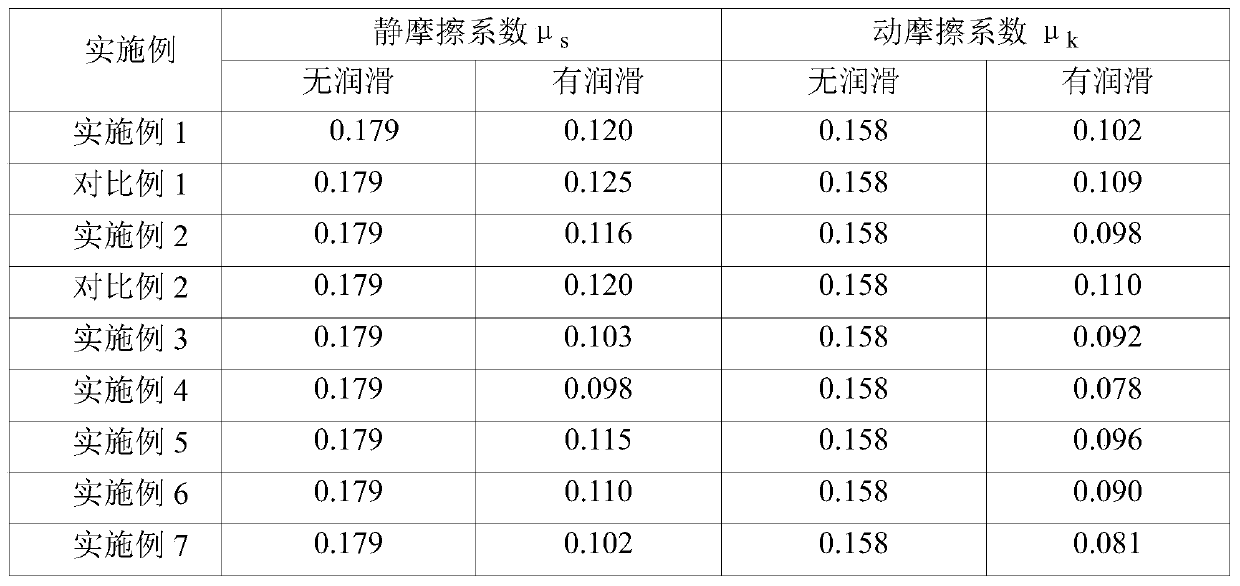

[0059] 100 parts by weight of mineral base oil Ib150 and 10 parts by weight of nitrile rubber particles to be dispersed VP401 are mixed and mechanically stirred evenly, then homogenized and circulated five times in a three-roll mill, and the roller speed is 280 rpm during homogenization, and the dispersion When the gap between the rolls is as small as 10μm, a mixed material is obtained. The above mixed material was kept in a high-temperature oven at 150°C for 4 hours, and then passed through a three-roll mill for homogenization and circulation five times. The roll speed during homogenization was 280 rpm, and the gap between the rolls was as small as 5 μm during dispersion to obtain a grease combination. See Table 1 and Table 2 for their dynamic viscosity, oil separation and lubricating properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com