Degradable polystyrene and preparation method thereof

A technology of polystyrene and general formula, which is applied in the field of degradable polystyrene and its preparation, can solve the problems of low number of blocks and easy occurrence of side reactions, achieve low carbonyl content, realize industrial application, and have good melt fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

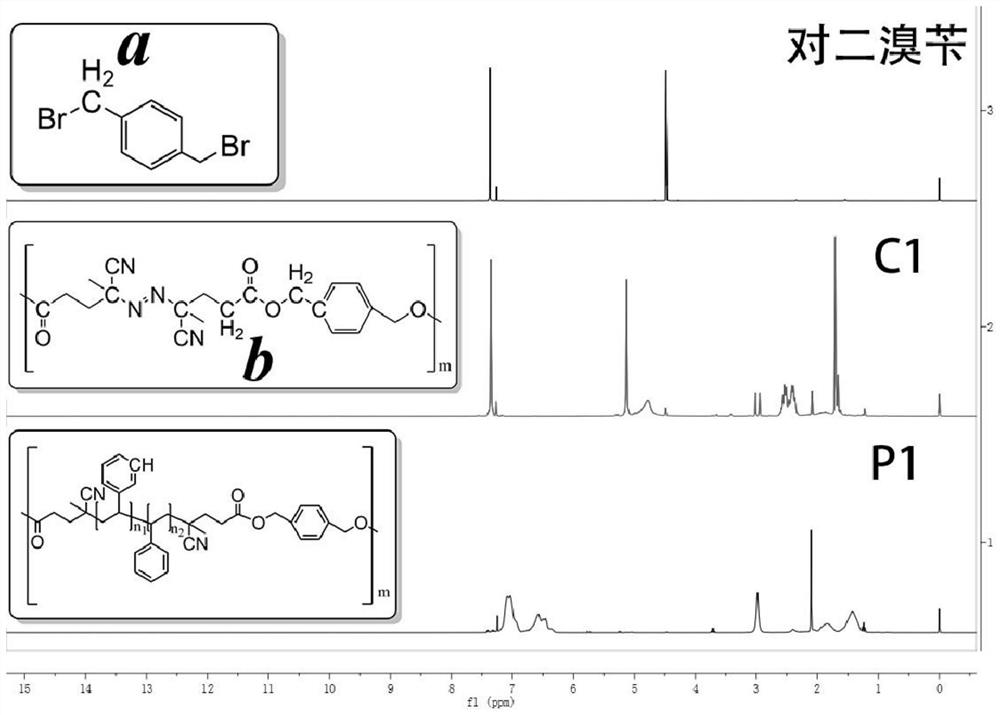

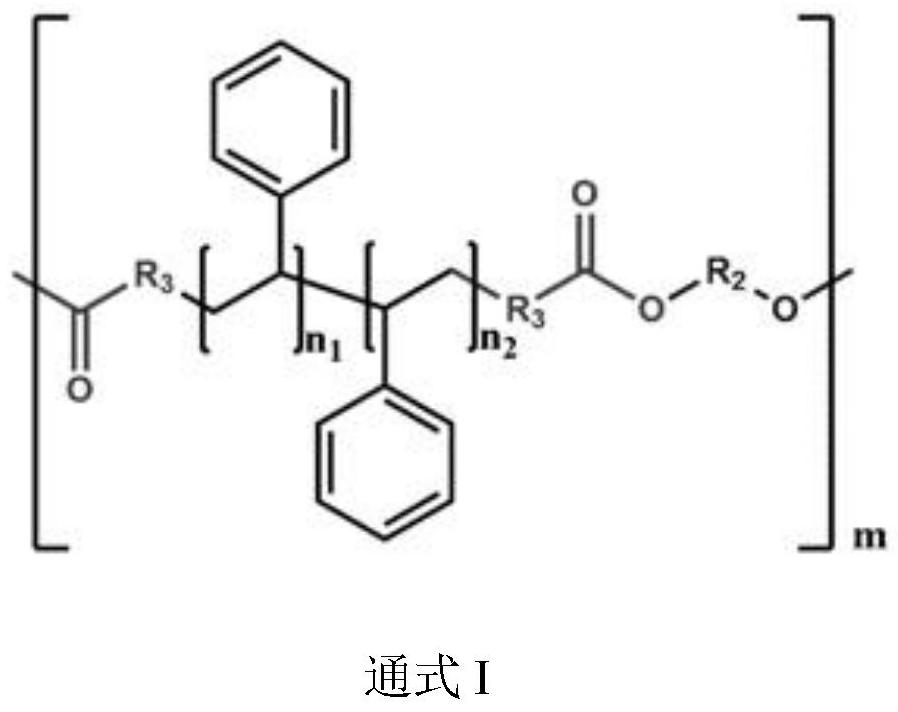

[0036] Embodiment 1: Preparation of P1

[0037] The preparation route is as follows:

[0038]

[0039] Among them, m and n represent: the repeating number of structural units in the polystyrene segment, wherein, n is determined by the ratio of the initiator to the monomer; m is determined by the ratio of azodicyanovaleric acid and p-dibromobenzyl .

[0040] Concrete preparation steps are as follows:

[0041](1) Synthesis of p-dibromobenzyl: sodium bromide (4.115g, 0.04mol), sodium bromate (3.018g, 0.02mol) was added to 70ml water; p-xylene (3.185g, 0.03mol) was added to In 70ml of dichloromethane; add sulfuric acid (2.94g, 0.03mol) to 40ml of water. The first two solutions are mixed, and the dilute sulfuric acid solution is added dropwise to the mixed solution, and the dropping rate is controlled at a drop rate of about 3 seconds, and the reaction is performed at room temperature for about 6 hours. After the reaction was completed, the product was washed with water thre...

Embodiment 2

[0044] Embodiment 2: the preparation of P2

[0045] The specific preparation steps are as follows: The specific preparation steps are as follows: the same part as in Example 1 will not be repeated, and the difference from Example 1 is that the molar ratio of the macroinitiator to the monomer styrene is 1:300.

Embodiment 3

[0046] Embodiment 3: the preparation of P3

[0047] The specific preparation steps are as follows: the same part as in Example 1 will not be repeated, and the difference from Example 1 is that the molar ratio of the macroinitiator to the monomer is 1:500.

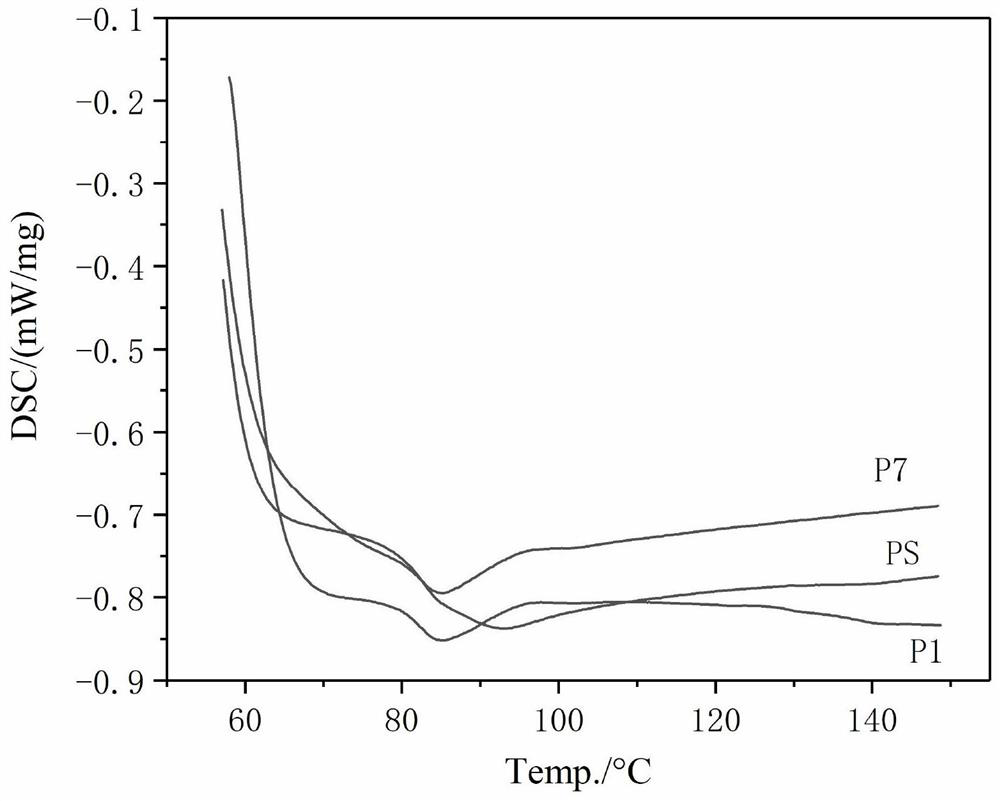

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com