Maintenance method for smoking of small oven ends of 7.63m coke oven

A furnace head and coke oven technology, which is applied in the maintenance field of smoke from the small furnace head of the 7.63-meter coke oven. Looseness and other problems, to achieve the effect of eliminating the phenomenon of smoke from the small burner, accurate materials, and powerful measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The maintenance method of the 7.63 meter coke oven small burner smoke of the present invention comprises the following steps:

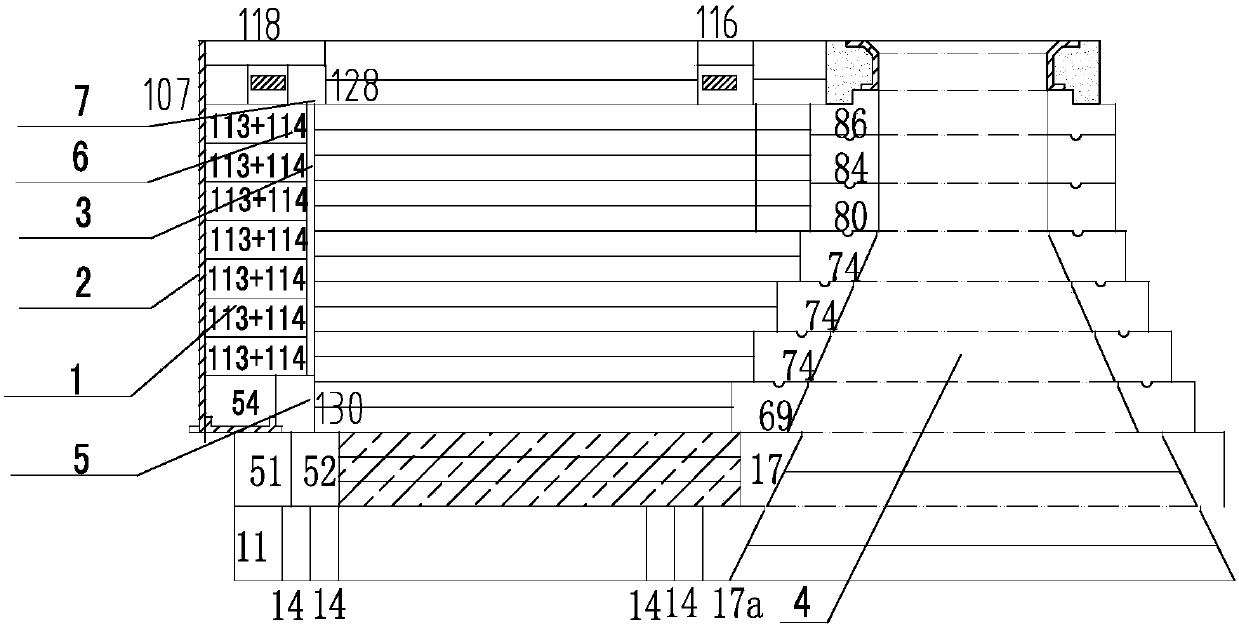

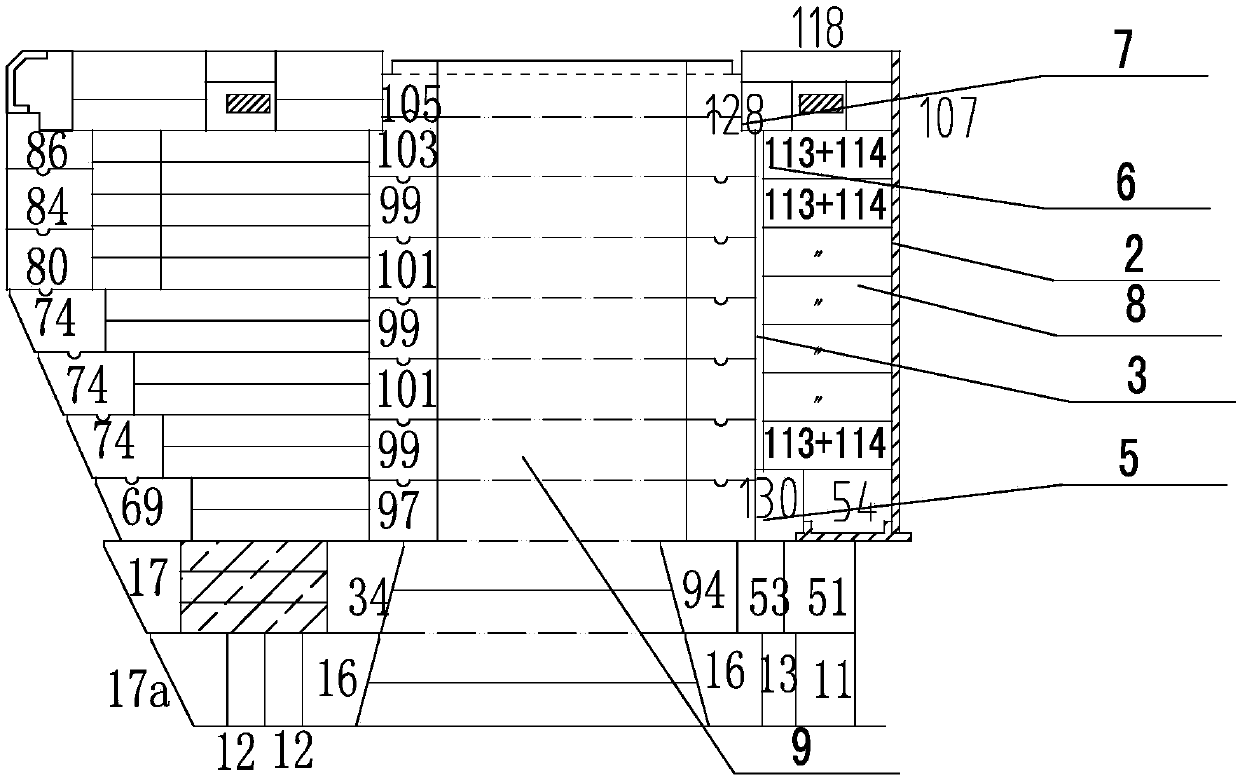

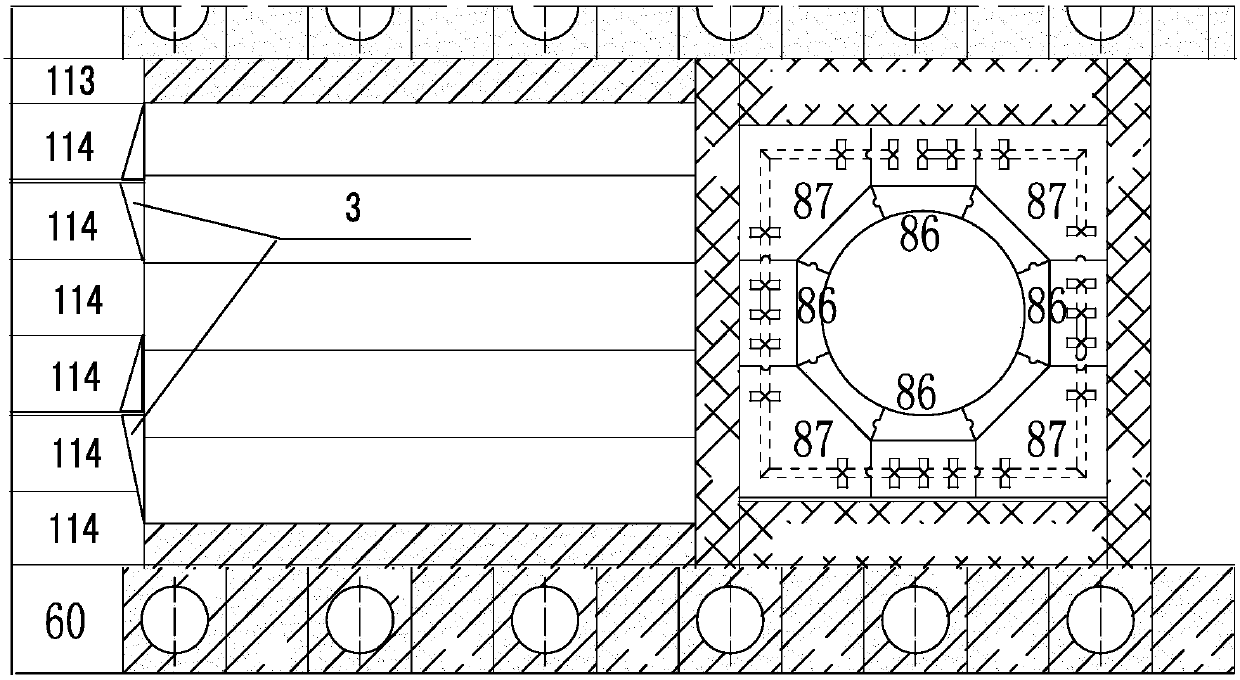

[0036] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the coke-side small furnace head in the embodiment of the present invention, figure 2 It is a schematic diagram of the structure of the small furnace head on the machine side according to the embodiment of the present invention. As shown in the figure, the outer side of the small burner 2 on the coke side and the inner side of the small burner 2 on the coke side are lined with refractory bricks, within the range of the third layer of refractory bricks to the eleventh layer of refractory bricks A grouting hole 3 is provided; also on the outer side of the small burner 2 on the machine side and the inner side of the small burner 2 on the coke side is lined with small burner refractory bricks, within the range of the third layer of refractory bricks t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com