Prefabricated green and ecological composite externally-hung insulation wallboard system

A prefabricated assembly and composite thermal insulation technology, applied to walls, building components, buildings, etc., can solve the problems of heavy weight, low utilization rate of new building materials, and easy damage, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

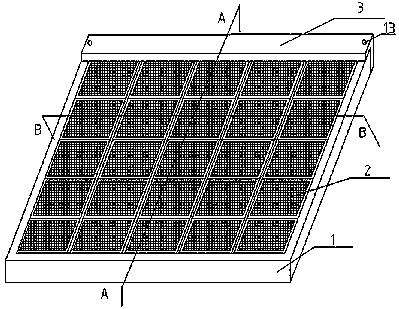

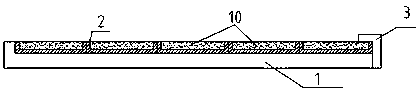

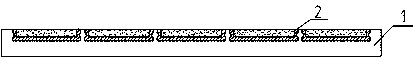

[0025] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is A-A sectional view of the present invention, image 3 It is a B-B sectional view of the present invention, Figure 4 is a perspective view of the wall of the present invention, Figure 5 is a perspective view of the ecological filling block of the present invention, Figure 6 is a perspective view of the plate cap of the present invention, Figure 7 It is a cross-sectional view when the ecological filling block of the present invention is not filled with raw soil, Figure 8 It is a cross-sectional view of the ecological filling block of the present invention when it is filled with planting soil. It is a prefabricated and assembled green ecological composite thermal insulation external wall panel system, including a wall 1, an ecological filling block 2 and a board cap 3. The wall 1 passes through The board cap 3 is fixedly connected with the ecological filling block 2 . The bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com