Method and device for testing air-conditioning filter screen cleanliness, electronic equipment and storage medium

A technology of air-conditioning equipment and detection methods, applied in the direction of mechanical equipment, etc., can solve the problems of low accuracy and high cost, and achieve the effect of solving relatively high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

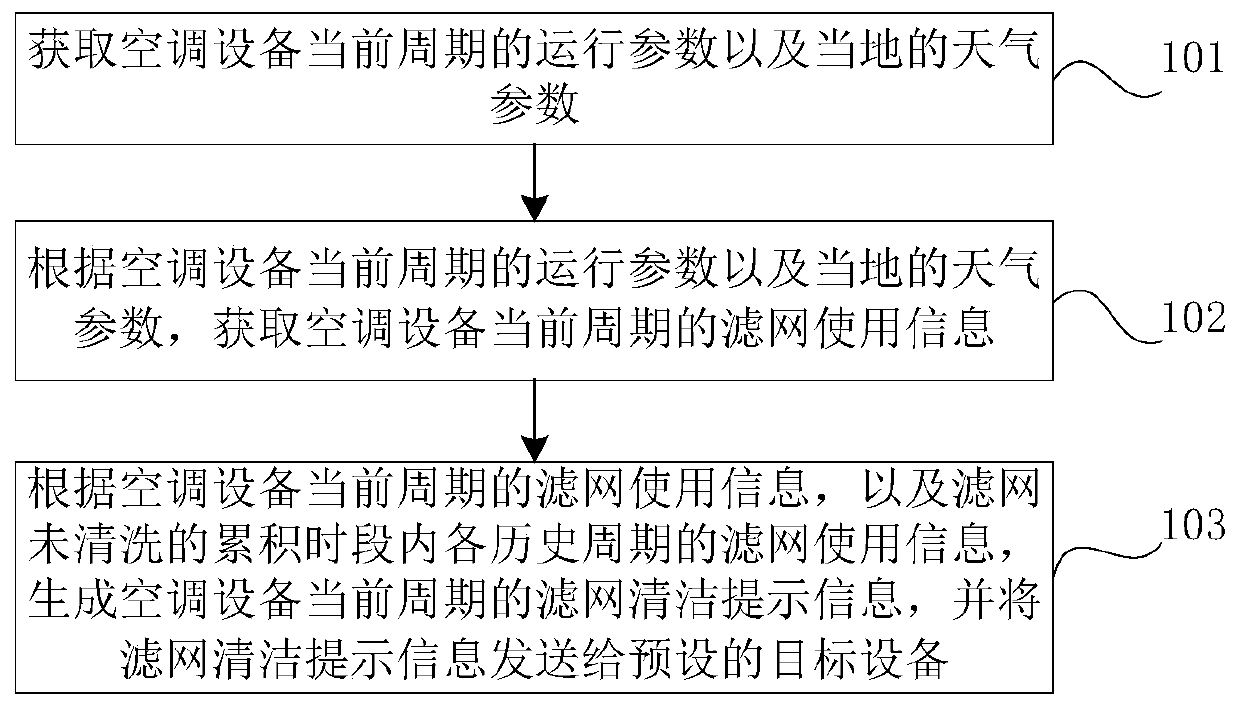

[0043] figure 1 It is a schematic flow chart of the method for detecting the cleanliness of an air conditioner filter provided in Embodiment 1 of the present application.

[0044] like figure 1 As shown, the method for detecting the cleanliness of the air-conditioning filter screen may comprise the following steps:

[0045] In step 101, the operating parameters of the current period of the air conditioner and the local weather parameters are obtained.

[0046] In practical applications, it is possible to control the start-up and shutdown of the air-conditioning equipment as required, and adjust its operating parameters such as wind speed, wind direction, and humidity during the operation of the air-conditioning equipment.

[0047] It can be understood that the operating parameters of the air conditioner in different cycles can be the same or different, and it can also be understood that the operating parameters of the air conditioner in the current cycle can be selected accord...

Embodiment 2

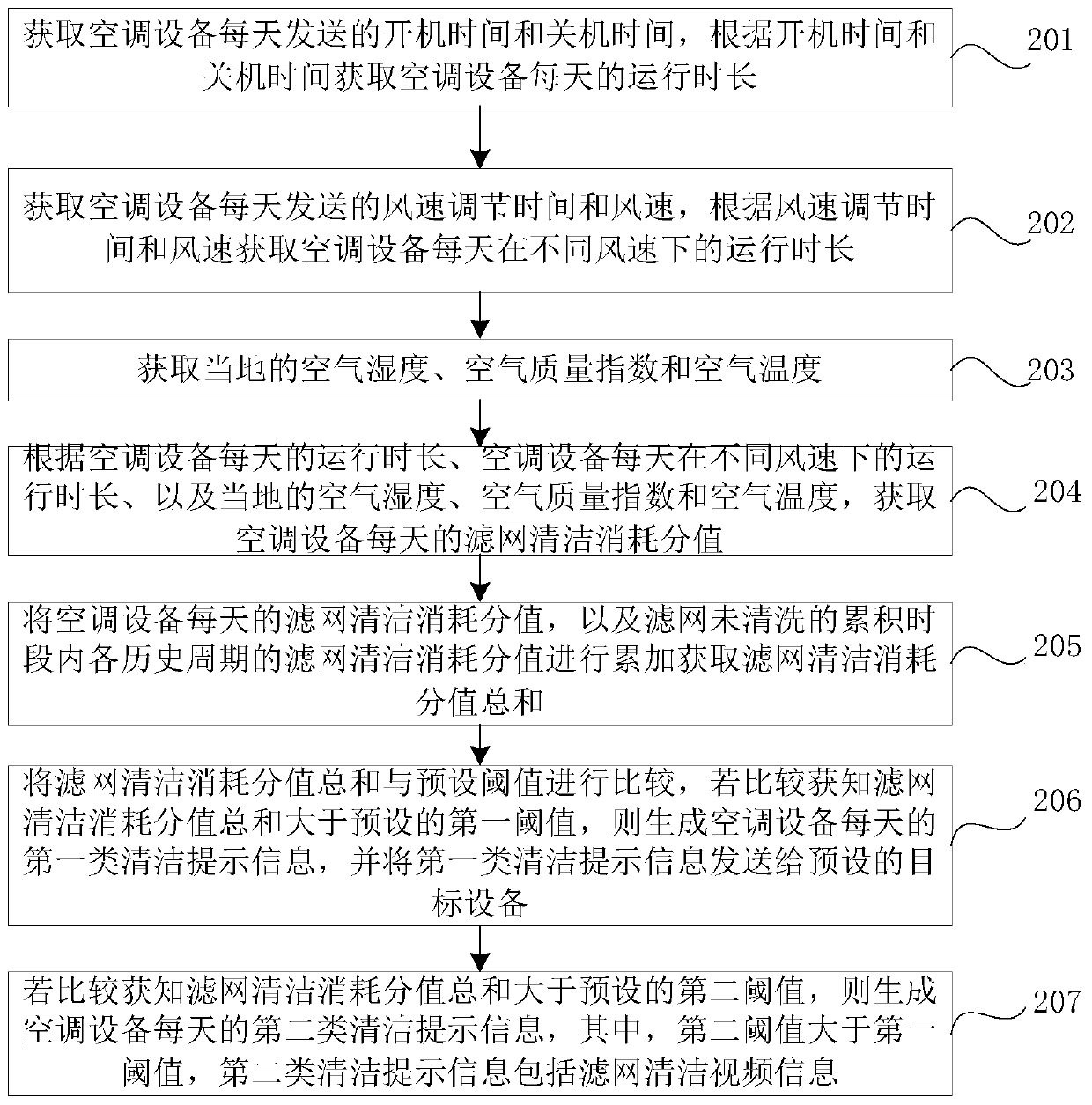

[0062] figure 2 It is a schematic flow chart of the method for detecting the cleanliness of an air conditioner filter provided in Embodiment 2 of the present application.

[0063] like figure 2 As shown, the method for detecting the cleanliness of the air-conditioning filter screen may comprise the following steps:

[0064] Step 201, obtain the startup time and shutdown time sent by the air conditioner through the Internet of Things protocol every day, and obtain the daily running time of the air conditioner according to the startup time and shutdown time.

[0065] Step 202, obtain the wind speed adjustment time and wind speed sent by the air conditioner through the Internet of Things protocol every day, and obtain the daily operating hours of the air conditioner at different wind speeds according to the wind speed adjustment time and wind speed.

[0066] Specifically, the current cycle is every day, that is, the startup time and shutdown time sent by the air conditioner t...

Embodiment 3

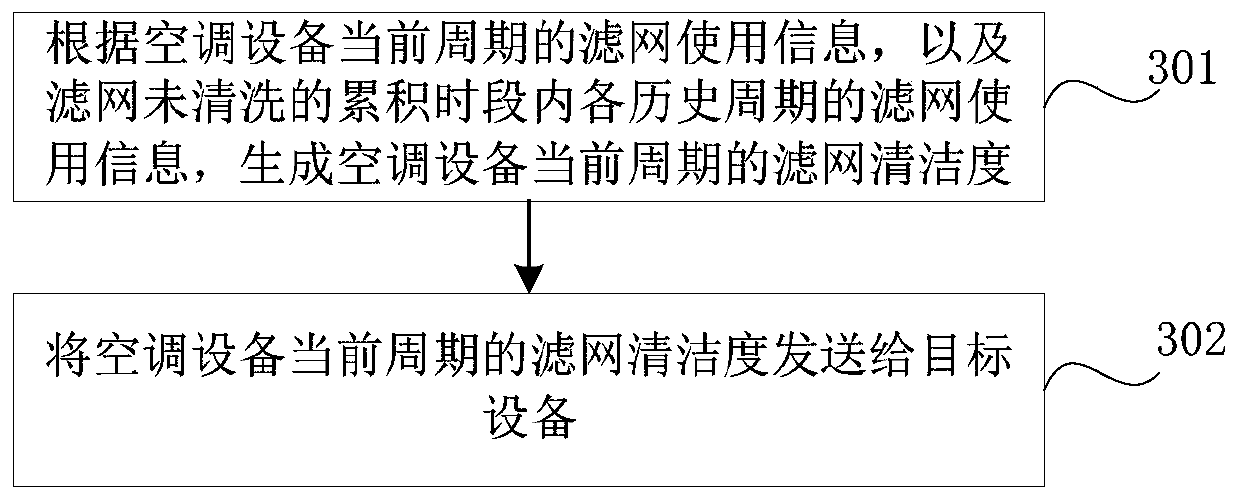

[0082] image 3 It is a schematic flowchart of the method for detecting the cleanliness of the air-conditioning filter screen provided by the third embodiment of the present invention.

[0083] like image 3 shown in figure 1 Step 102 of and figure 2 After step 204, the method for detecting the cleanliness of the air-conditioning filter screen may also include the following steps:

[0084] Step 301 : Generate filter cleanliness for the current cycle of the air conditioner according to the filter usage information of the current cycle of the air conditioner and the filter usage information of each historical cycle during the accumulated period of time when the filter has not been cleaned.

[0085] Step 302, sending the filter screen cleanliness of the air conditioner in the current period to the target device.

[0086] Specifically, the clean filter screen after cleaning or first use can be considered as 100% clean. As the use time goes by, the filter screen usage informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com