Simulation test method and system of large-diameter soil pressure shield tunnel driving interface

A simulation test system and technology of shield tunneling, which is applied in the field of simulation test of excavation surface of large-diameter earth pressure shield tunnels, can solve problems such as large differences in excavation behavior and inability to reflect pressure fluctuations in soil bins during large-diameter shield excavation construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a large-diameter earth pressure shield tunnel excavation interface simulation test system. By setting different water level heights, simulating different excavation speeds, monitoring the seepage process, soil tank pressure fluctuation, soil layer deformation and the axial force of the excavation surface, In order to study the groundwater seepage law and instability characteristics of large-diameter shield tunneling surface in permeable strata.

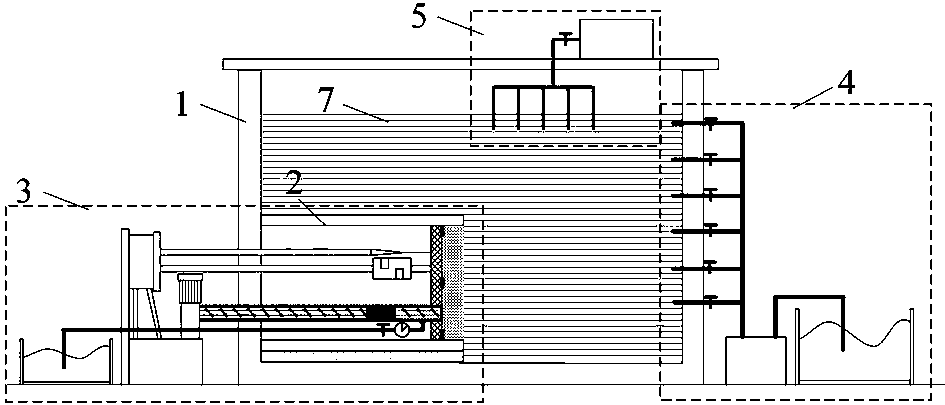

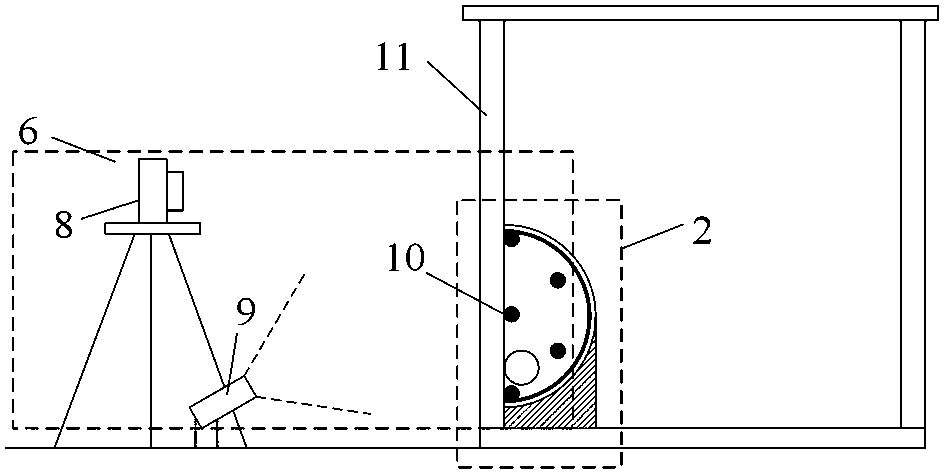

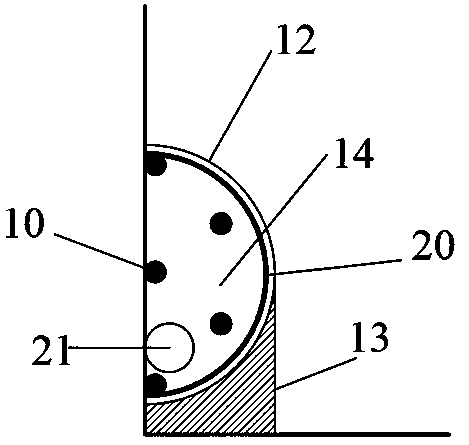

[0042] see attached figure 1 And 2, the simulation test system provided by this embodiment includes a model box 1, a shield model 2, a shield tunneling system 3, a water level control device 4, a seepage tracer device 5 and a monitoring system 6. The model box is a rectangular open box on the upper part, which is used to fill the soil sample 7 and place the shield model 2; the surrounding panels of the model box 1 are transparent tempered glass plates, which are convenient for external monitoring and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com