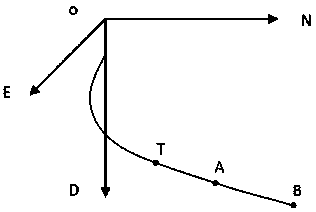

Three-dimensional horizontal well borehole trajectory design method

A wellbore trajectory and design method technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as increasing the difficulty and complexity of problems, design and on-site construction resistance, and increasing constraints, so as to improve reliability Implementability, reduce construction risk, and improve the effect of success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

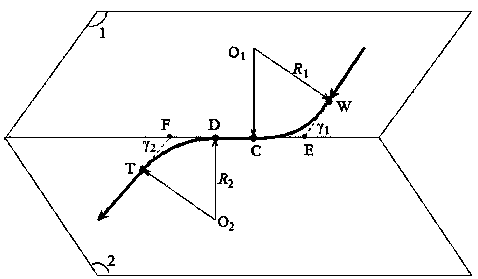

[0102]The well is a three-dimensional horizontal well with an offset of 171.94m and a displacement in front of the target of 596.41m. The specified parameters are as follows:

[0103] Target A: vertical depth: 1476.86m, north-south: 571.08m, east-west: 171.94m;

[0104] Target B: vertical depth: 1469.40m, north-south: 1321.13m, east-west: 171.94m;

[0105] Kick-off point: vertical depth 880m;

[0106] Slope building rate: the first arc segment: 4.8° / 30m, the second arc segment (increase and azimuth segment): 4.8° / 30m, the third arc segment: 3.6° / 30m.

[0107] According to the present invention, do following calculation steps:

[0108] Step 1: Well section design before the target

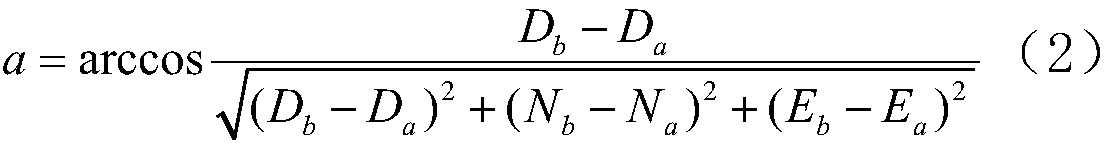

[0109] (1) Calculate the inclination angle and azimuth angle of the line connecting the target points

[0110] Since the vertical depth, north-south, and east-west of the two target points A and B are known, formulas (2) and (3) can be used to quickly calculate the inclination angle and azimuth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com