Vacuum cooking utensil and method for determining food material quantity in cooking utensil

A cooking utensil and vacuum technology, which is applied in the field of vacuum cooking utensils, can solve the problems of high cost and inaccurate detection of ingredients, and achieve the effects of low cost, shortened detection time, and avoiding hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

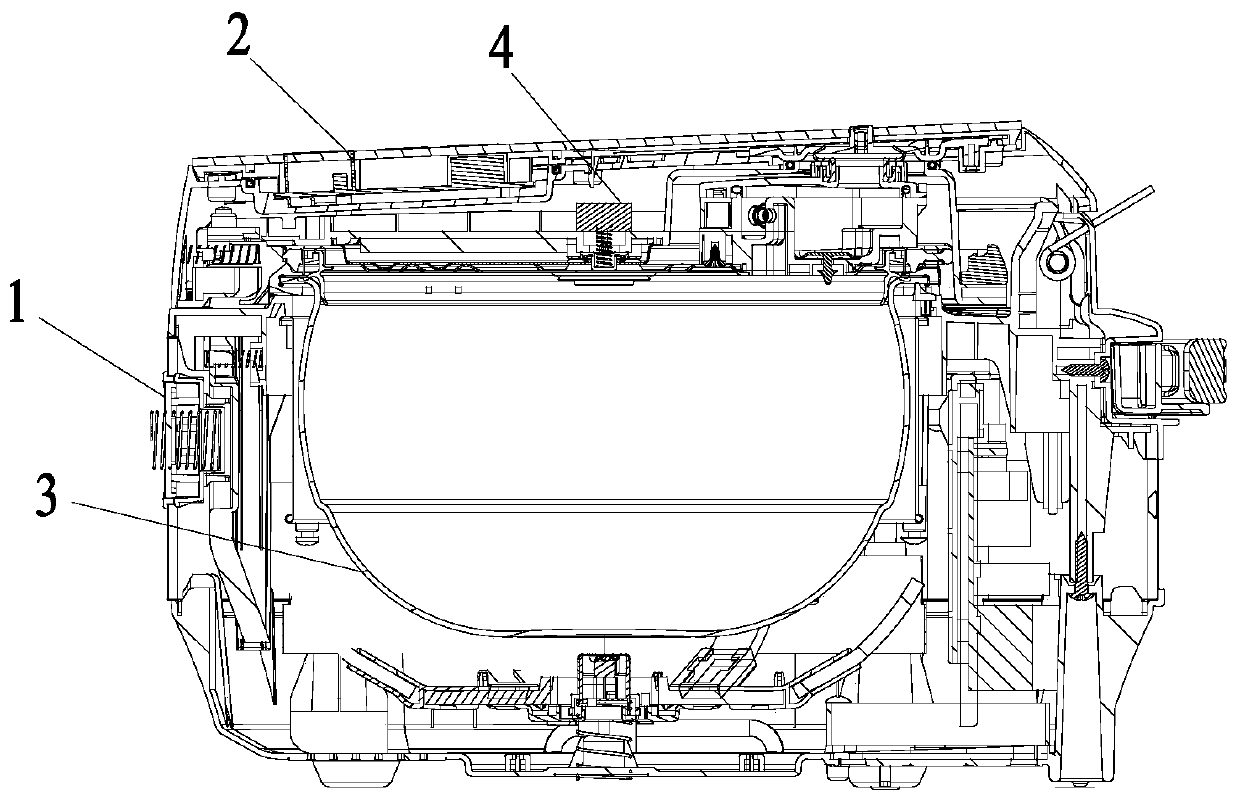

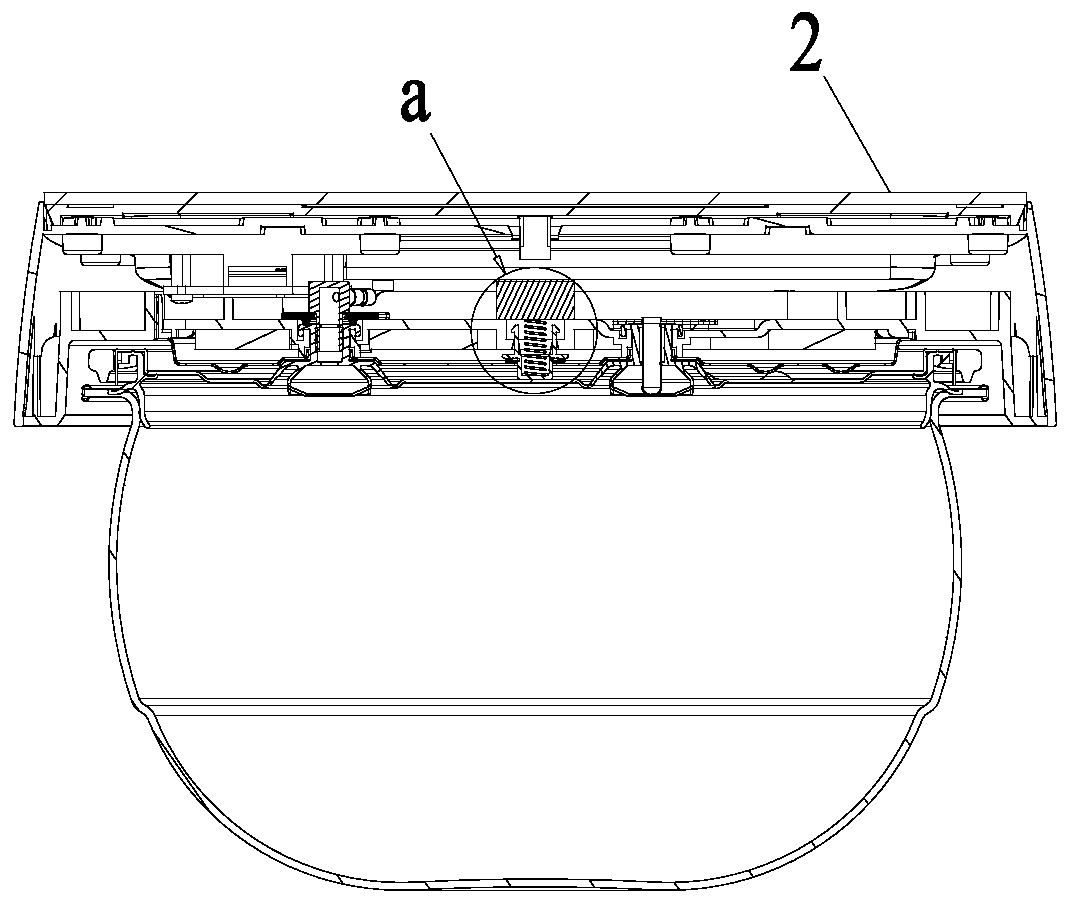

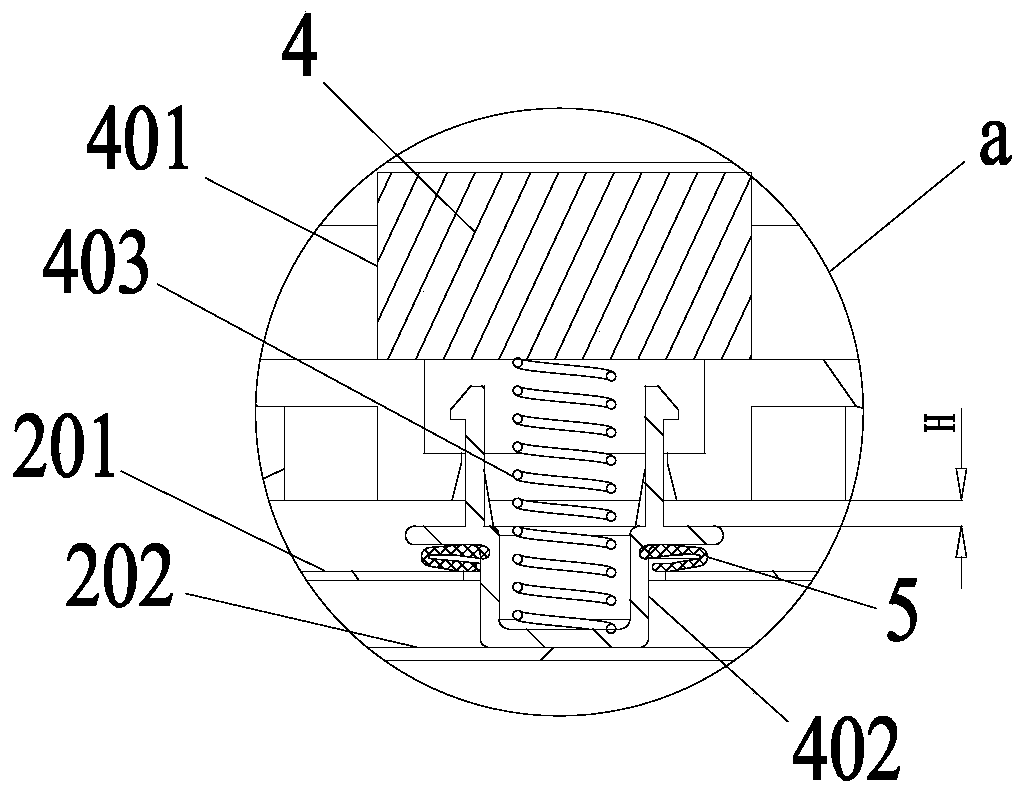

[0046] figure 1 It is a cross-sectional view of a vacuum cooking appliance according to an embodiment of the present invention; figure 2 It is a cross-sectional view of a pot cover in an embodiment of the present invention; image 3 for figure 2 The enlarged picture at a in the middle; figure 1 , figure 2 and image 3 As shown, the vacuum cooking appliance provided by the embodiment of the present invention includes a pot body 1 and a pot cover 2 covering the pot body 1. The pot body 1 is provided with an inner pot 3, and the inner pot 3 has a cavity with an upward opening. When the cover 2 is arranged on the pot body 1, the pot cover 2 and the inner container 3 are combined to form a cooking cavity. The pot body 1 or the pot cover 2 is equipped with an air extraction device, which is used to extract air from the vacuum cooking utensils at a constant air extraction rate, that is, to extract air from the cooking cavity surrounded by the combination of the pot cover 2 an...

Embodiment 2

[0059] The main structure of the vacuum cooking appliance in this embodiment is basically the same as the main structure of the vacuum cooking appliance in the first embodiment, the difference is that the pressure detection device includes a current detection unit and a pressure determination unit connected to each other, the current detection unit and the air extraction device The connection is used to detect the current signal of the air extraction device; the pressure determination unit is used to determine the pressure signal in the vacuum cooking appliance according to the current signal detected by the current detection unit. In this embodiment, according to the different load currents of the air extraction device under different air pressure states, the pressure signal of the vacuum cooking appliance at this time is judged by detecting the current of the air extraction device.

[0060] Further, the current detection unit includes a sequentially connected current detectio...

Embodiment 3

[0064] The main structure of the vacuum cooking appliance in this embodiment is basically the same as the main structure of the vacuum cooking appliance in the first embodiment, the difference is that the pressure detection device is a pressure sensor, and the pressure sensor communicates with the vacuum cooking appliance, which can directly detect the pressure inside the vacuum cooking appliance. The pressure signal of the pressure detection device makes the pressure detected by the pressure detection device more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com