Preparation method of smoke-free folium artemisiae argyi and folium artemisiae argyi box thereof

A technology of wormwood and wormwood stove, which can be applied to medical preparations containing active ingredients, pharmaceutical formulations, and instruments for heating/cooling reflection points, etc. problem, to achieve the effect of ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing smokeless wormwood, comprising the following steps: air-drying and air-drying the wormwood to be processed, and air-drying the humidity to 15%RH; ℃, maintained for 1.5 h; continued to heat up to 150 °C, maintained for 4 h; cooled to 15 °C to obtain smokeless wormwood; rolled the smokeless wormwood paper into wormwood rolls.

[0046] Preferably, the smokeless wormwood forms a porous structure during the carbonization process.

[0047] Preferably, the heat power of the smokeless wormwood reaches 1000KJ / kg.

[0048] Preferably, the mugwort oil is pre-condensed and condensed into an oily state, which is recovered from a cooling tank.

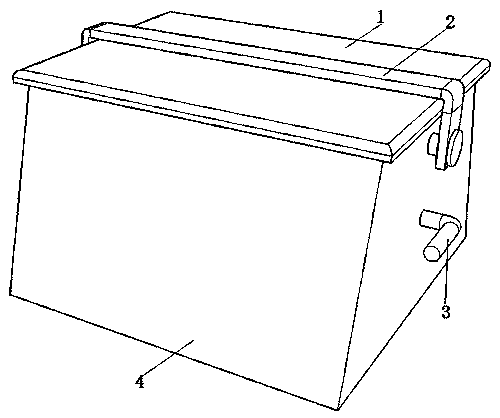

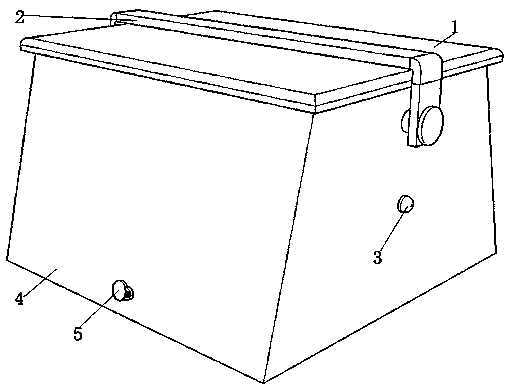

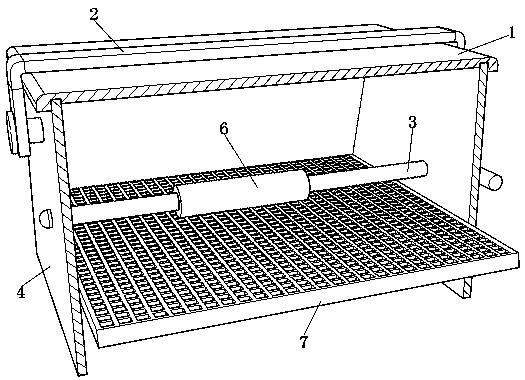

[0049] according to Figure 1 to Figure 6 Shown: a kind of wormwood box, comprising: wormwood roll 6, sleeved on the fixed rod 3, the fixed rod 3 passes through the wormwood box 4, the fixed rod 3 is provided with a handle, and the handle is provided with a The outside of the wormwood case 4; the steel wire mesh 7 is...

Embodiment 2

[0054] A method for preparing smokeless wormwood, comprising the following steps: sunning and air-drying the wormwood to be processed, and air-drying the humidity to 20%RH; ℃, maintained for 1.5 h, carbonized the wormwood to remove harmful substances in the wormwood; continued to raise the temperature to 170 ℃, maintained for 4.5 hours, removed the wormwood oil in the wormwood, and preserved the medicinal properties of the carbonized wormwood ; cooling down to 15°C to obtain smokeless wormwood; rolling the smokeless wormwood into a wormwood roll.

[0055] Preferably, the smokeless wormwood forms a porous structure during the carbonization process.

[0056] Preferably, the heat power of the smokeless wormwood reaches 1000KJ / kg.

[0057] Preferably, the mugwort oil is pre-condensed and condensed into an oily state, which is recovered from a cooling tank.

[0058] according to Figure 1 to Figure 6 Shown: a kind of wormwood box, comprising: wormwood roll 6, sleeved on the fixed ...

Embodiment 3

[0063] A method for preparing smokeless wormwood, comprising the following steps: air-drying and air-drying the wormwood to be processed, and air-drying the humidity to 30%RH; ℃, maintained for 3h; continued to heat up to 190°C, maintained for 5h; cooled to 15°C to obtain smokeless wormwood; rolled the smokeless wormwood paper into a wormwood roll.

[0064] Preferably, the smokeless wormwood forms a porous structure during the carbonization process.

[0065] Preferably, the heat power of the smokeless wormwood reaches 1000KJ / kg.

[0066] Preferably, the mugwort oil is pre-condensed and condensed into an oily state, which is recovered from a cooling tank.

[0067] according to Figure 1 to Figure 6 Shown: a kind of wormwood box, comprising: wormwood roll 6, sleeved on the fixed rod 3, the fixed rod 3 passes through the wormwood box 4, the fixed rod 3 is provided with a handle, and the handle is provided with a The outside of the wormwood case 4; the steel wire mesh 7 is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com