Double-barrel gas-liquid separator

A gas-liquid separator and separator technology, which is applied in separation methods, dispersed particle separation, liquid degassing, etc., can solve the problems of single applicable flow pattern, small separator usable range, and inability to oscillate the efficient operation of the flow pattern, etc., to achieve Guarantee the effect of efficient operation and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

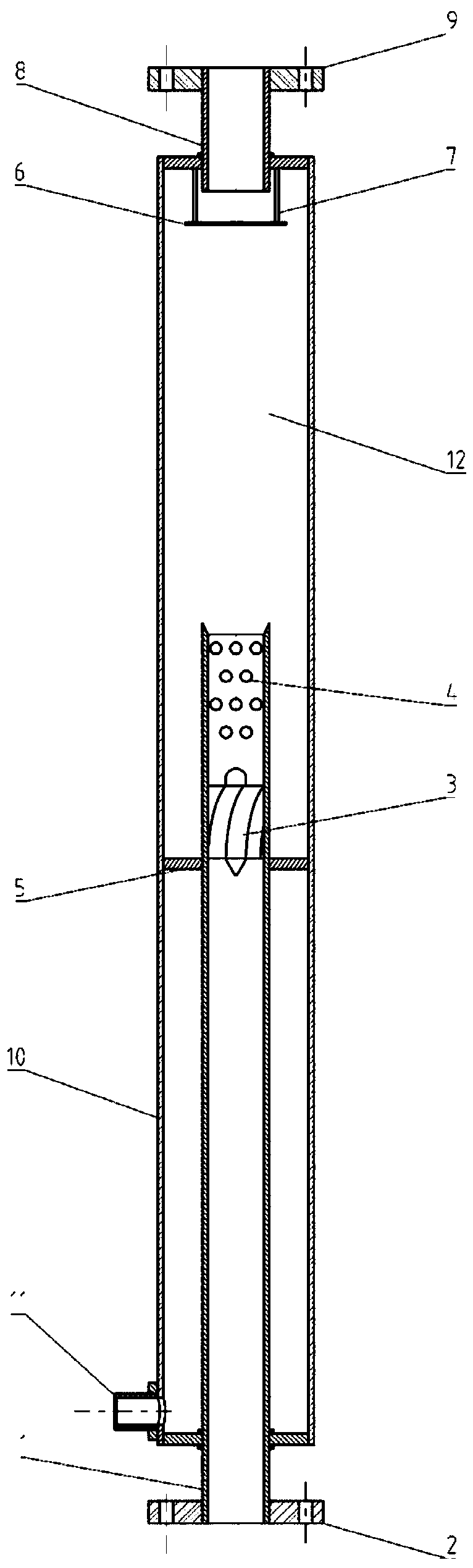

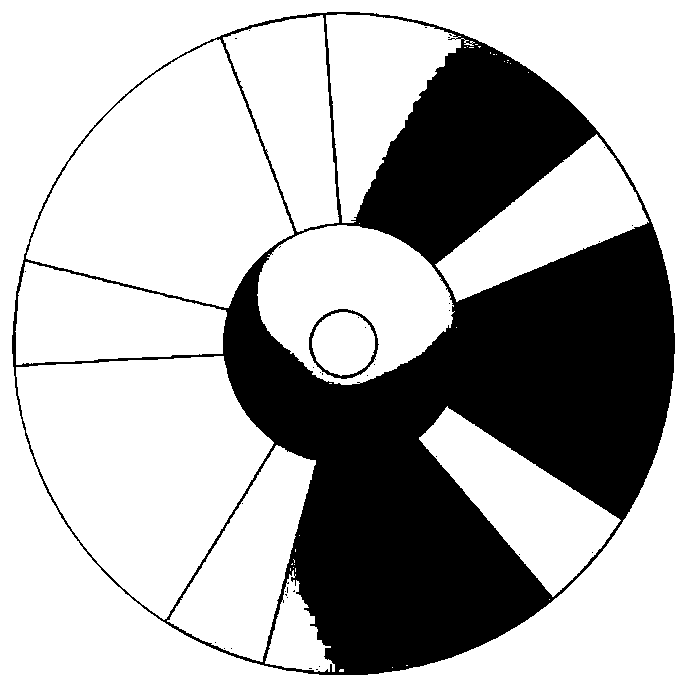

[0023] combine Figure 1-3 , a double-barrel gas-liquid separator of the present invention, including an inner cylinder body 1, an inlet flange 2, an impeller 3, a liquid discharge section 4, an anti-vibration strip 5, a separation baffle 6, a separation baffle tie bar 7, and a separator Gas phase outlet 8, outlet flange 9, outer cylinder 10, separator liquid phase outlet 11, gravity separation chamber 12. The gas phase outlet 8 of the separator is located at the top of the separator, and the liquid phase outlet 11 is located at the bottom of the outer cylinder 10; the inlet end of the gas-liquid mixture of the inner cylinder 1 is located outside the outer cylinder 10, and the outlet end is located at the outer cylinder 10 inside; the impeller 3 is arranged in the middle and upper part of the inner cylinder 1, and a liquid discharge section 4 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com