Superfine rice grading equipment

A technology of rice and equipment, which is applied in solid separation, separation of solids from solids by air flow, and sieving, etc., can solve the problems of high misjudgment rate and inaccuracy, and achieve the effect of easy equipment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following embodiments, unless specifically defined, the so-called front-rear direction is defined by the running direction of the upper belt body of the corresponding conveyor belt (including the first conveyor belt and the second conveyor belt). For example, if the upper belt runs from left to right, the left is the front, the right is the rear, and so on.

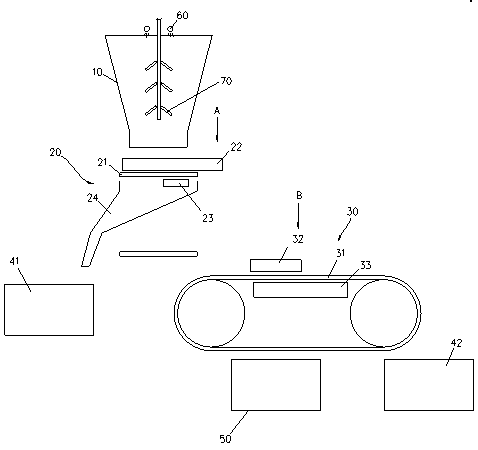

[0030] Examples, see Figure 1 to Figure 5 Shown: Extra-grade rice grading equipment, used to screen out rice grains with a diameter greater than D and a length greater than H. Of course, the specific values of D and H can be set according to needs.

[0031] in particular:

[0032] The extra-grade rice grading equipment includes a lower hopper 10, a diameter screening system 20, a length screening system 30, a first circulation barrel 41, a second circulation barrel 42, a refined barrel 50, and the like.

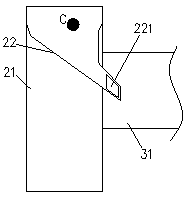

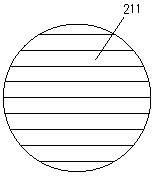

[0033] The diameter screening system 20 includes a first conveyor belt 21 . The front portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com