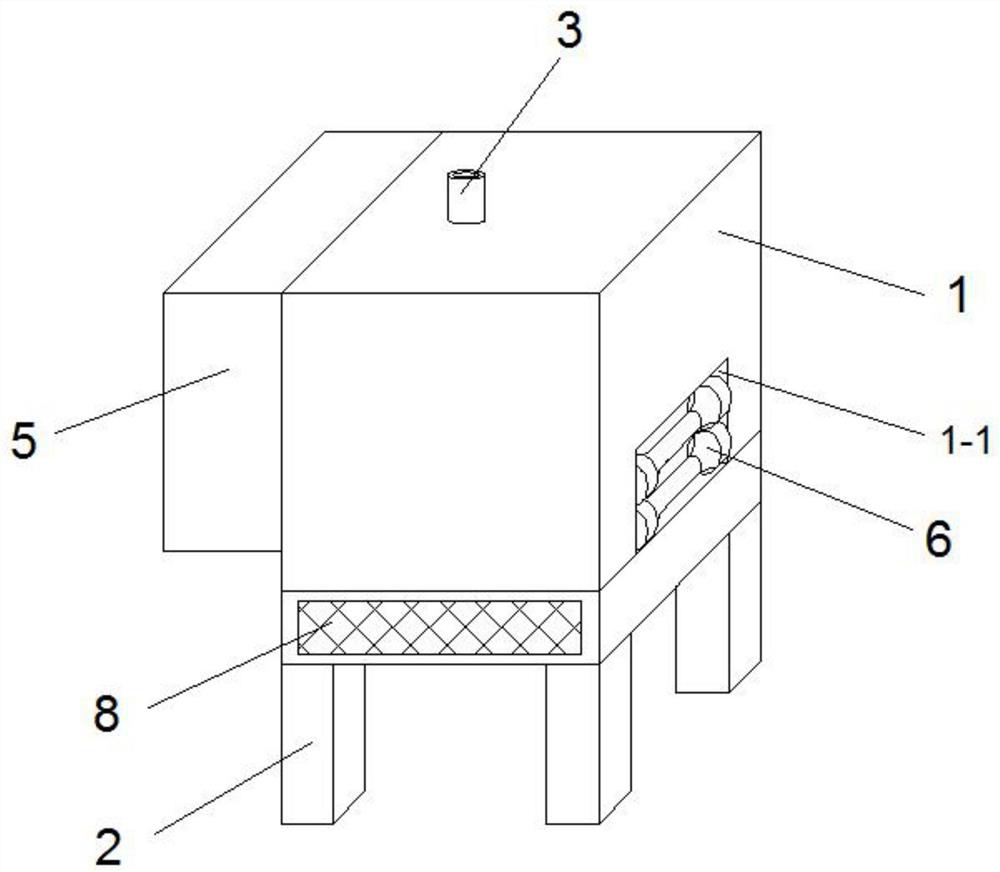

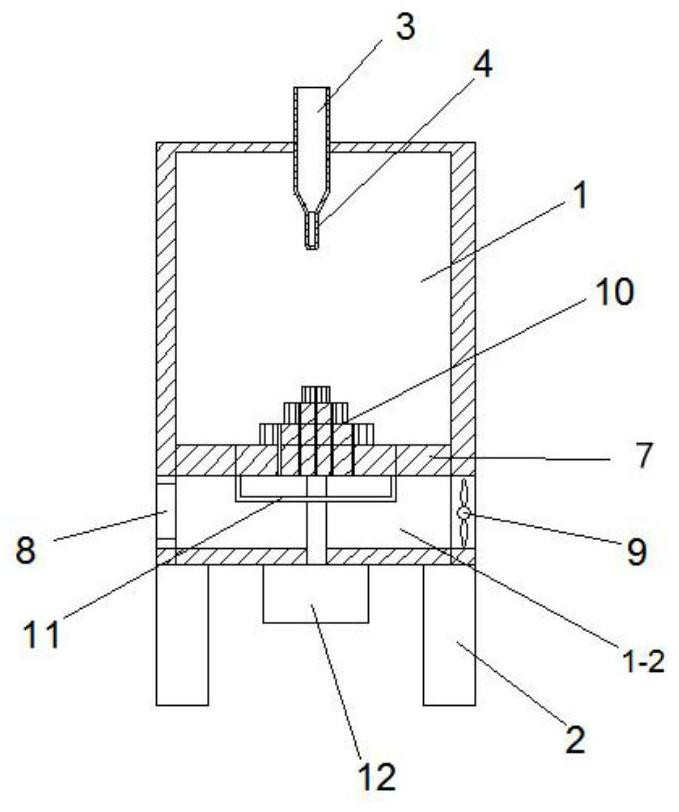

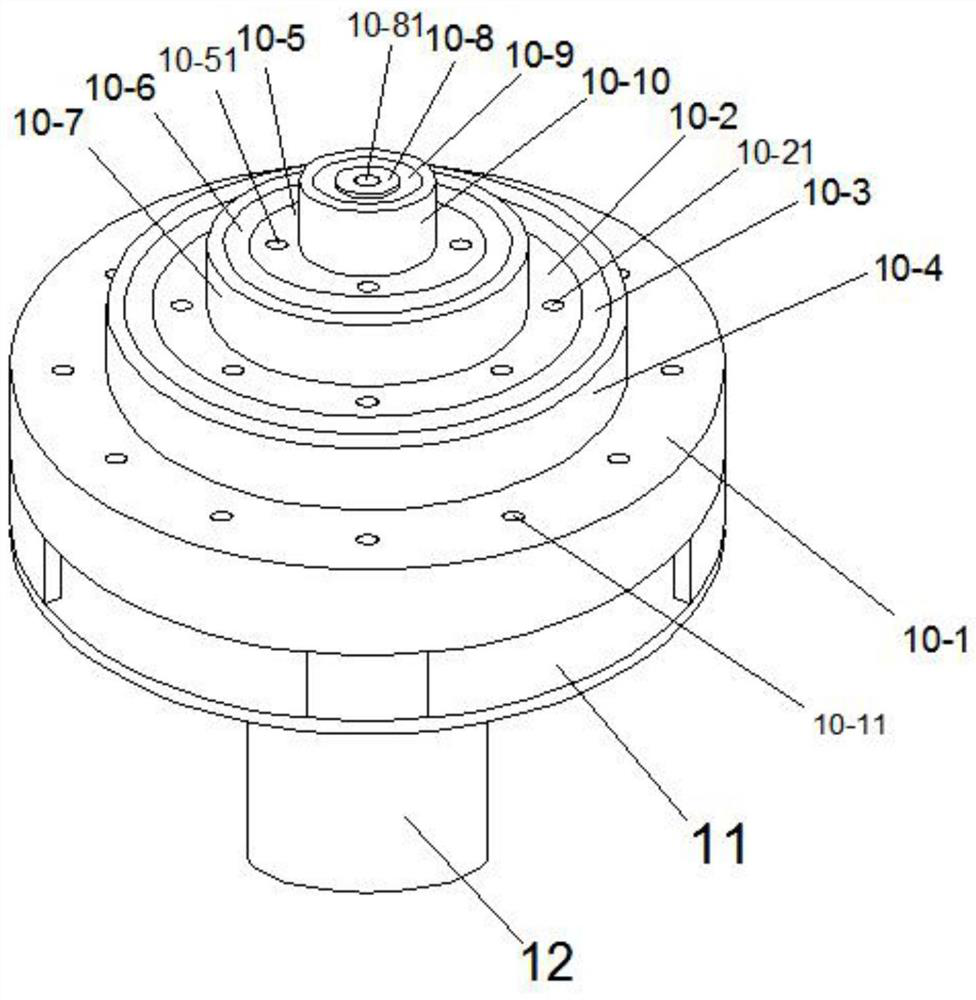

An electrospinning machine for preparing nanofibers with high adsorption performance

An electrospinning machine, nanofiber technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems affecting the quality and efficiency of fiber yarn winding, poor system operation stability, and fiber yarn winding quality. It can achieve the effect of strong structural operation stability, improved stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are all well-known technologies known to those skilled in the art, such as one-time concrete pouring, welding, and the like. The rotating motor mentioned in the present invention is a common three-phase asynchronous AC motor, and the negative pressure fan mentioned is a low-speed DC fan, which are all products that can be purchased directly in the market, and their structural principles are well known to those in the field Known technology, will not be repeated in the present invention.

[0023] It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com