Safe automatic drainage system

An automatic drainage and safety technology, applied in the water supply pipeline system, water supply equipment, water supply main pipeline, etc., can solve the problems that cannot meet the needs of production, safety hazards, cooling water spillage, etc., achieve low cost and reduce safety risks , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

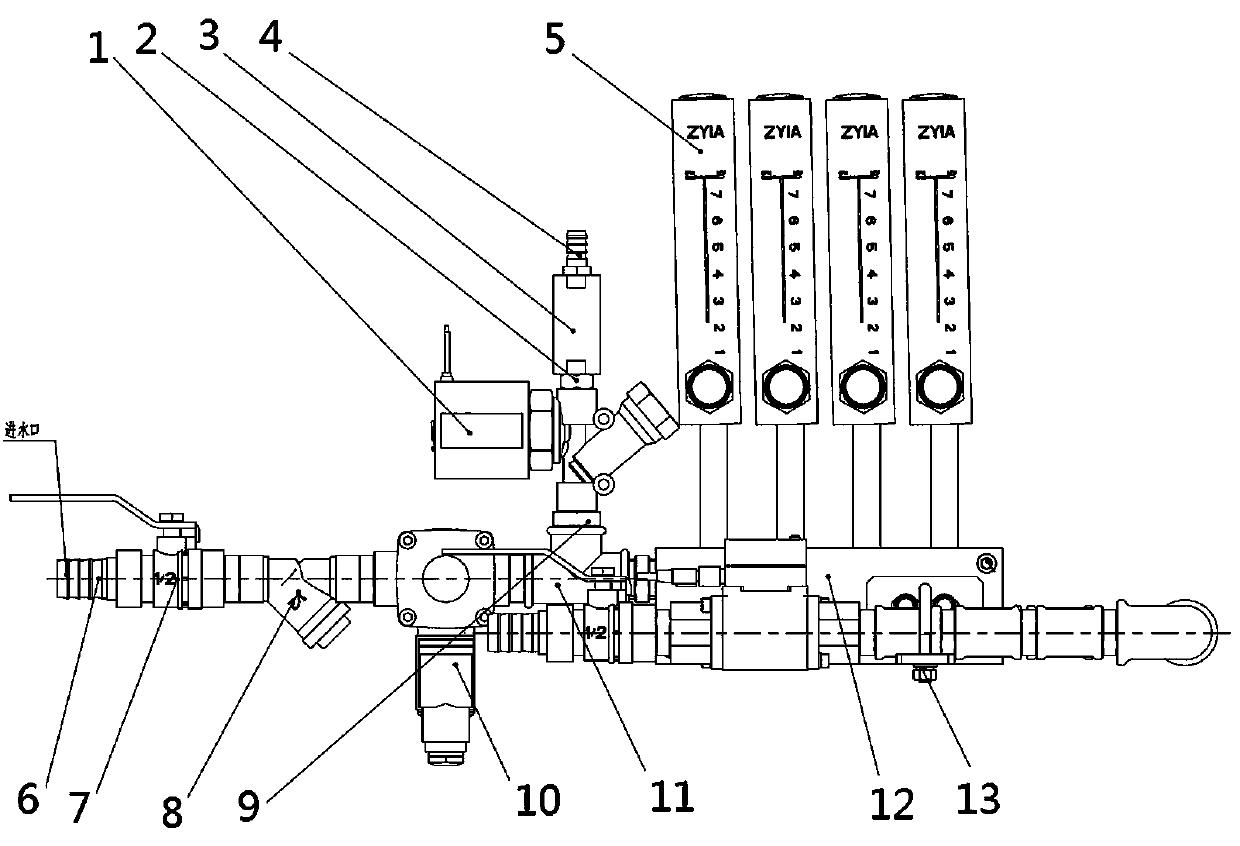

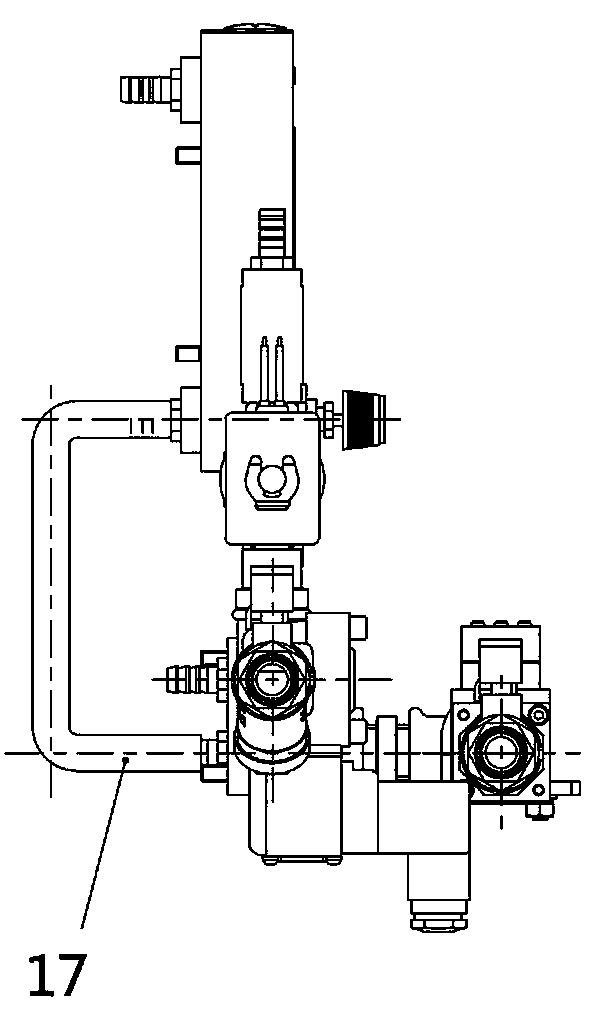

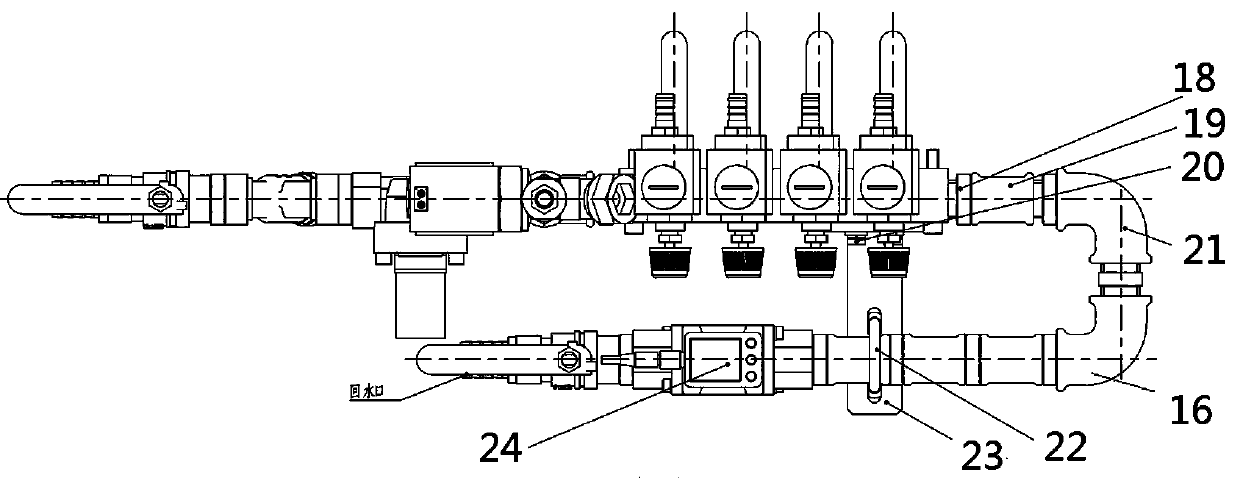

[0018] Please refer to the figure, in the embodiment of the present invention, a safe automatic drainage system includes a second straight-through tower joint 6, a four-point ball valve 7, a Y-shaped filter 8, a first straight-through pipe joint 9, and a pilot-operated two-way Solenoid valve 10, inner thread tee 11 and water diversion plate 12; the second straight-through tower joint 6 is connected to the cold water pipe to allow cooling water to enter, and the rear side of the second straight-through tower joint 6 is sequentially connected with a four-point ball valve 7. Pilot-operated two-way solenoid valve 10, inner thread three-way 11, water diversion plate 12, second straight-through pipe joint 18, outer joint 19, four-point inner tooth elbow joint 21, pipeline 16 and digital flow switch for water 24. The four-point ball valve 7 controls the on-off of the cooling water entering the second straight-through tower joint 6. The main function of the pilot-operated two-way solen...

Embodiment 2

[0023] On the basis of Example 1, a Y-shaped filter 8 is communicated between the four-point ball valve 7 and the inner thread tee 11 to filter the cooling water entering the second straight-through tower joint 6 to prevent impurities from entering To the cooling system, reduce internal impurities and ensure smooth cooling water.

[0024] The cooling water 6 enters, circulates and cools through the water distribution plate 12 according to each water channel, and then flows back into the pipeline 16 through the water distribution plate 12, and finally is discharged from the water outlet (the water is discharged from the rear side of the digital flow switch 24). When parts need to be replaced, the cooling water in the water channel needs to be discharged, the pilot two-way solenoid valve 10 closes the water channel, stops water intake, and the built-in filter Y-type direct-acting two-way solenoid valve 1 starts to work. At this time, the pipeline is opened, and the upper The gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com