Automatic drainage device for positive pressure pipeline

An automatic drainage and pipe pressure technology, which is applied in the direction of valve devices, pipe components, engine components, etc., can solve the problems of pipeline pressure loss, affecting production safety, and inapplicability, so as to reduce the internal and external pressure difference, improve operation accuracy, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

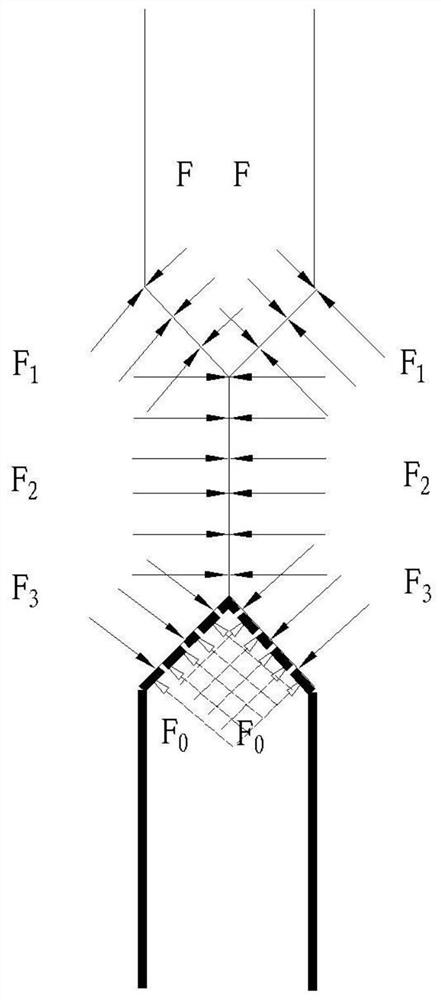

[0023] image 3 Schematic diagram of the force-bearing structure of an elastic thin tube figure 1 ; Figure 4 Schematic diagram of the force-bearing structure of an elastic thin tube figure 2 ; Figure 5 Schematic diagram of the force-bearing structure of an elastic thin tube image 3 ;

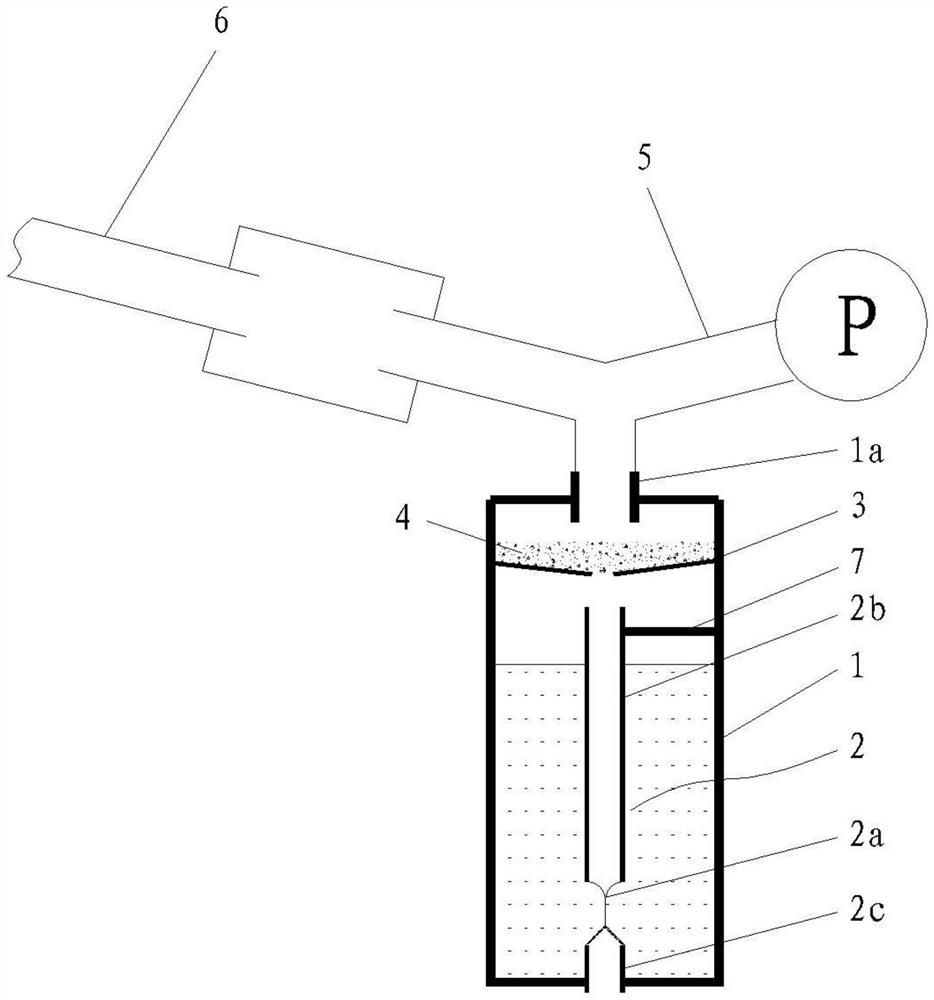

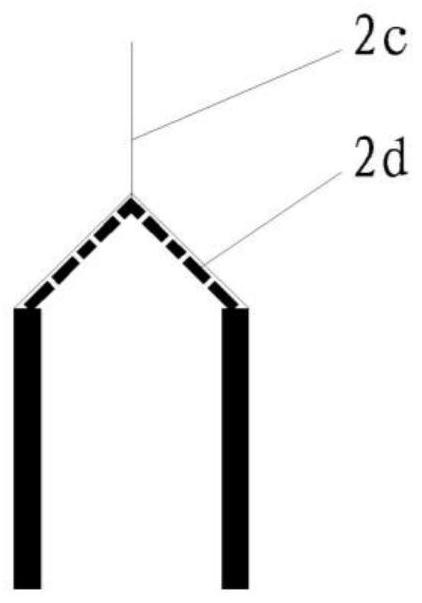

[0024] This embodiment provides a positive pressure pipeline automatic drainage device, which includes a water discharge bucket 1 and a water discharge pipe assembly 2 installed in the water discharge bucket. The upper end of the water discharge pipe assembly is used to receive the water flow in the pressure measuring tube. The lower end of the water discharge pipe assembly is connected to the water outlet of the water discharge bucket, and the middle or bottom section of the water discharge pipe assembly is an elastic thin tube 2a. The middle section is the middle position between the upper end and the lower end of the water discharge pipe assembly, and the bottom section is the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com