Enclosing wall easy to disassemble and assemble

A technology that is easy to disassemble and assemble walls, applied to walls, building components, buildings, etc., can solve problems such as poor heat preservation, sound insulation, high manual labor intensity, and inconvenient movement, and achieve low manual labor intensity, high work efficiency, Good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

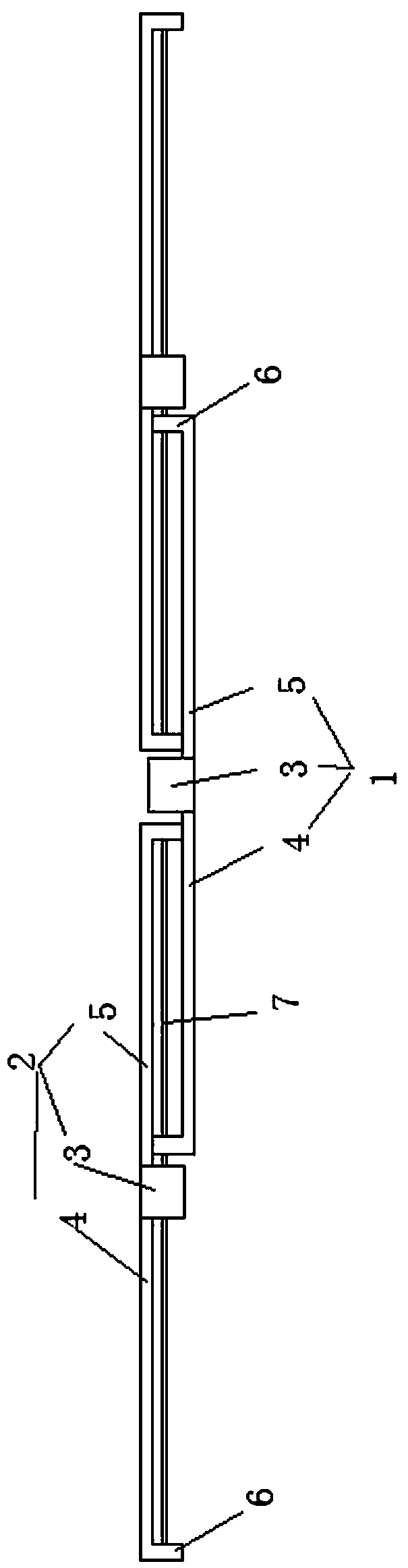

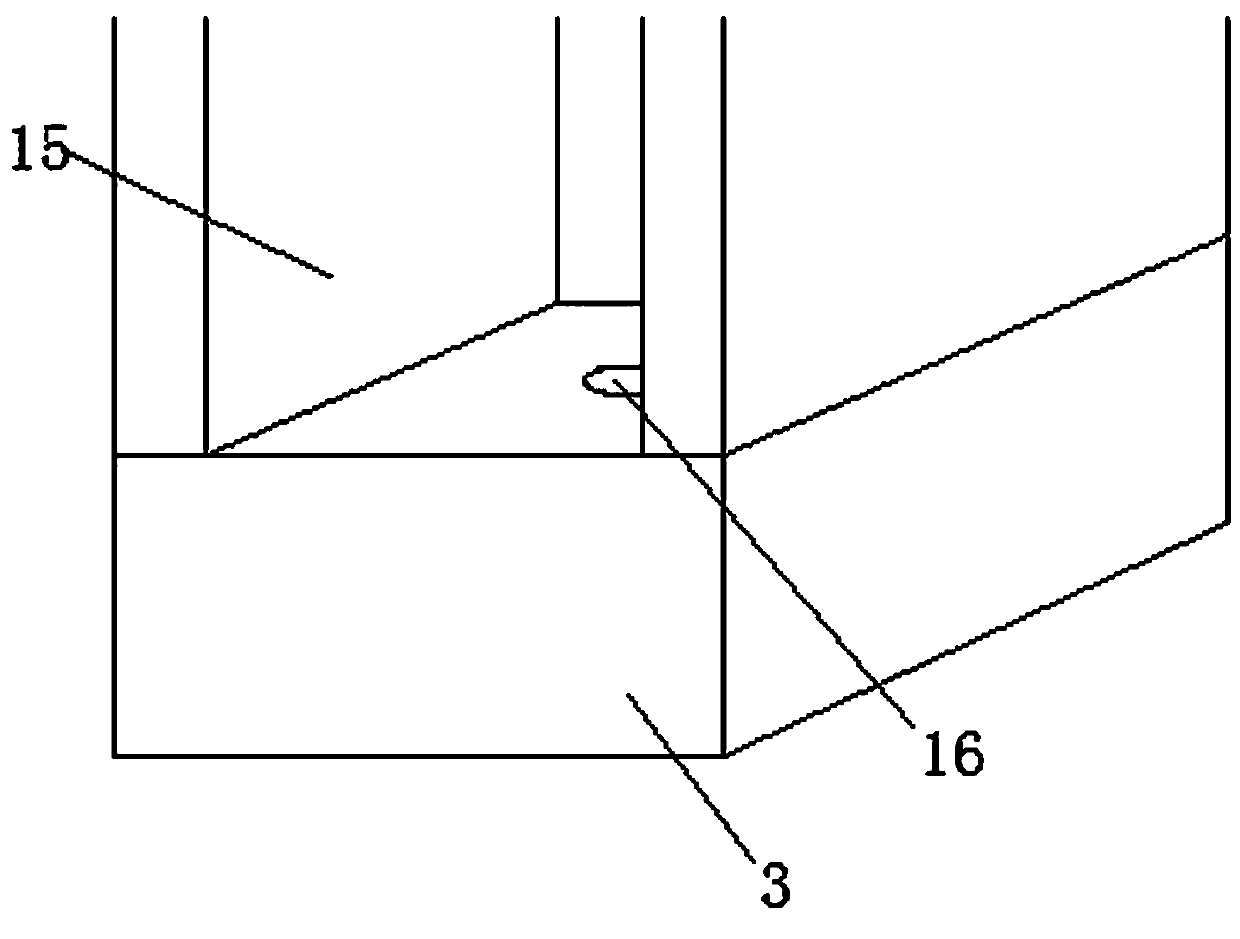

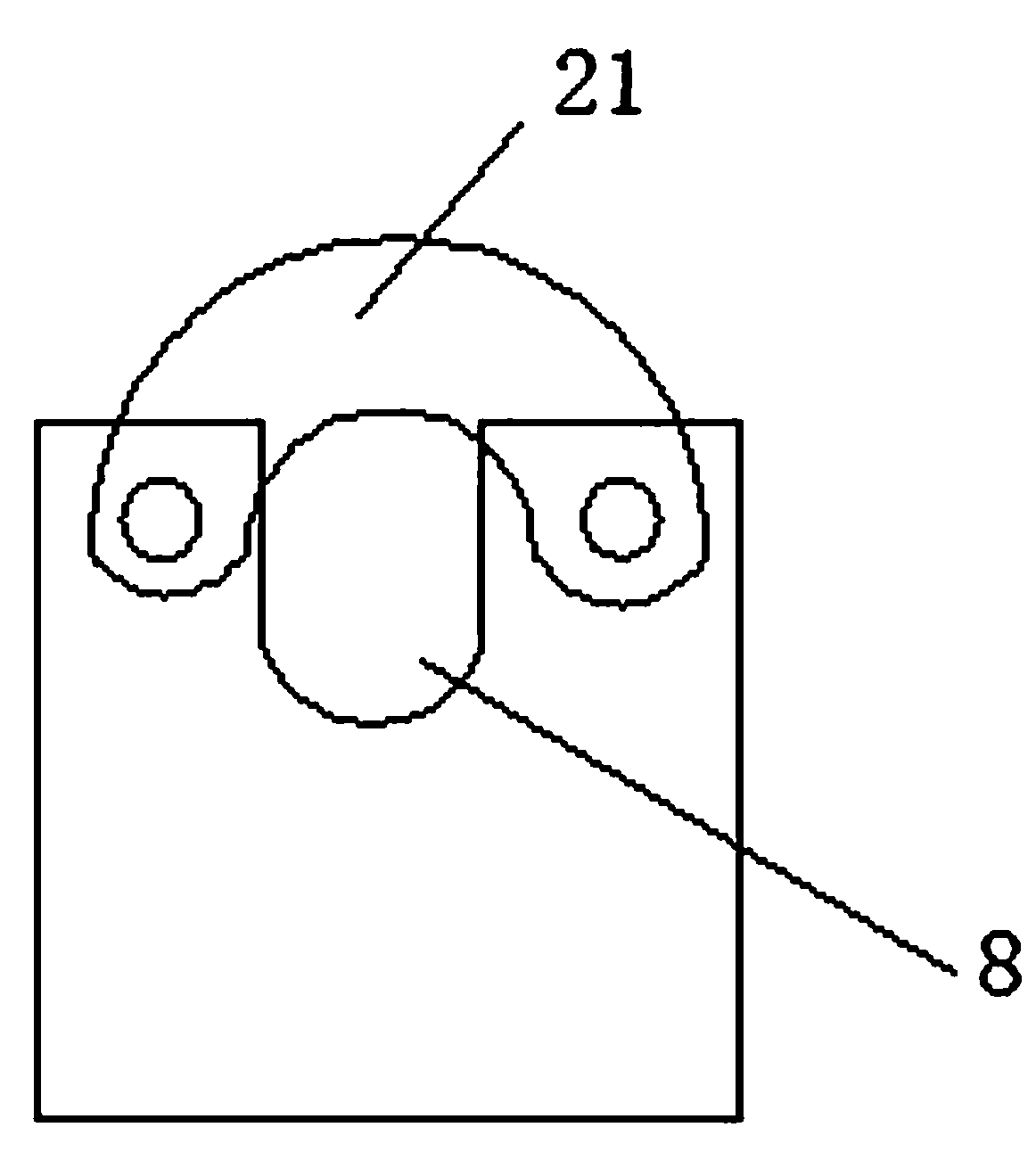

[0029] See attached picture.

[0030] An easily disassembled and assembled enclosure, comprising inner and outer panel assemblies 1 and 2 cooperating with each other, the inner and outer panel assemblies 1 and 2 respectively include uprights 3, and the two sides of the uprights 3 are respectively provided with Coaming boards 4 and 5, the two ends of the coaming boards 4 and 5 are respectively provided with limit plates 6 which are turned inwardly, and a space is provided between the columns 3 of the peripheral plate assembly 2 and the limit plates 6 The guide rod 7 is set, and the limit plate 6 of the inner wall assembly 1 is provided with guide grooves 8 correspondingly matched with the guide rods, the inner wall assembly 1 is located 1. Peripheral plate assemblies 1 and 2 are matched correspondingly, and arranged adjacently and continuously in sequence. Positioning grooves 9 are respectively provided at the upper ends of the surrounding plates 4 and 5, and a surrounding plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com