Novel wall and construction process thereof

A new type of wall technology, applied in the field of building structure thermal insulation, can solve problems such as easy displacement, and achieve the effects of simple and convenient construction, low preparation and processing costs, and no potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

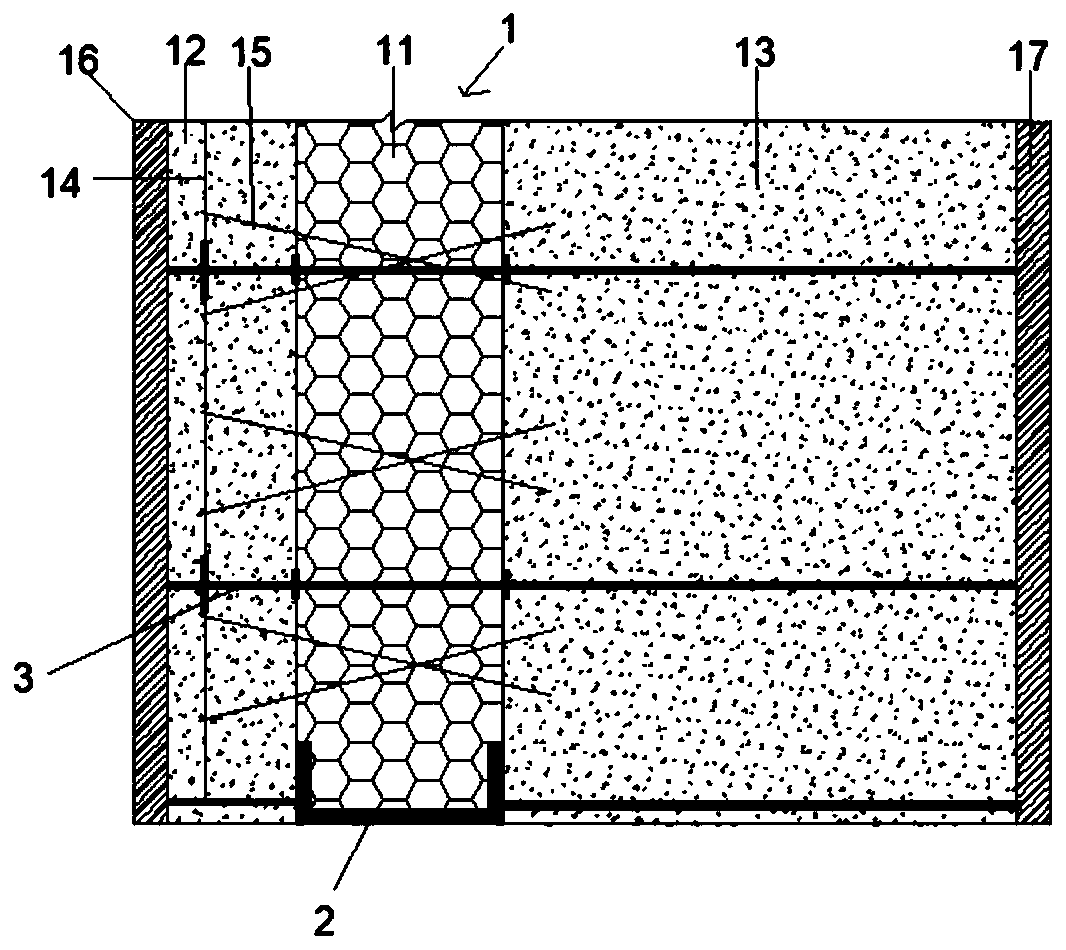

[0051] Such as figure 1 As shown, a new type of wall can fix the steel wire grid insulation board when building the wall insulation board. It includes at least one steel wire grid insulation board 1, at least one new-type insulation board bottom limit support 2 and at least one new steel wire grid insulation board positioning support 3.

[0052] in:

[0053] The steel wire grid insulation board 1 includes a central insulation board 11 and a steel wire grid. Both sides of the insulation board 11 have a first pouring layer and a second pouring layer for cast-in-place. The first pouring layer and / or the second pouring layer are cast-in-place structures, which are respectively called the first pouring structure 12 and the second pouring structure 13 after pouring. The second pouring layer is the space where the shear wall reinforcement is located. The wire mesh frame includes abdominal wires 15 and steel wire mesh sheets 14 located in the first pouring layer. The abdominal wire...

Embodiment 2

[0062] Such as Figure 7 Shown, a kind of construction technology of the novel body of wall of embodiment 1 comprises the following steps:

[0063] (1) binding shear wall reinforcement;

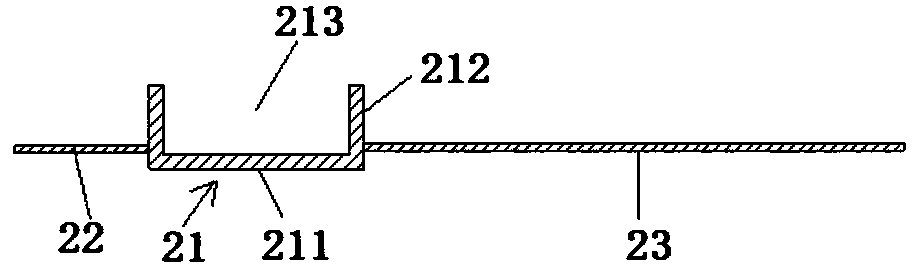

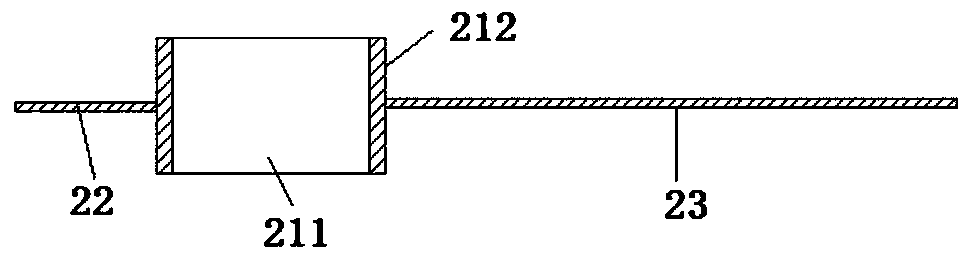

[0064] (2) Place the limit support member 2 at the bottom of the new insulation board on the location of the insulation board 11;

[0065] (3) install the steel wire grid insulation board 1, make the insulation board 11 be stuck in the U-shaped draw-in groove 213 of the first member 21, thereby fix the insulation board 11;

[0066] (4) Pass the rod on the right side of the support rod 31 of the new steel wire grid insulation board positioning support 3 and the first support 32 through the mesh of the steel wire mesh sheet 14, so that the rod passes through the insulation board 11, so that the first A support bracket 32 leans against the left side of the insulation board 11 to limit the displacement of the insulation board 11 to the outside, and a second support bracket 33 leans against th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com