Water-driven heat exchange enhanced type heating radiator

A technology that enhances heat exchange and hydraulic drive, applied in the field of heating and heating, can solve problems such as limited heat dissipation, limited side walls and partition walls, and failure to meet the design requirements of radiators in motor vehicle maintenance depots, so as to speed up airflow and increase convection Effect of heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

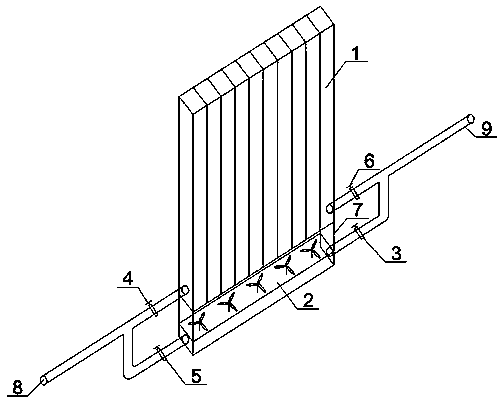

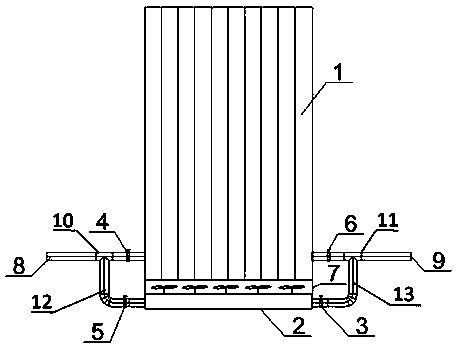

[0025] Such as figure 1 As shown in the figure, a hydraulically driven radiator with enhanced heat exchange includes a radiator 1, a water supply pipe 8 for water supply is provided on the left side of the radiator 1, and a return pipe 9 for water return is provided on the right side of the radiator 1. The radiator 1 is provided with a hydraulic fan 2 driven by the pressure difference between supply and return water, and the airflow blown by the hydraulic fan 2 enhances the heat exchange of the radiator 1 .

[0026] The hydraulic fan 2 is arranged below the radiator 1, and the air outlet of the hydraulic fan 2 faces the radiator 1.

[0027] A connecting piece 7 is provided between the hydraulic fan 2 and the radiator 1 .

[0028] The connecting piece 7 is a connecting plate or a connecting frame.

[0029] The water supply pipe 8 is provided with a water supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com