A cable force real-time monitoring device and monitoring method

A real-time monitoring and cable force technology, which is applied in the field of bridge engineering and construction, can solve the problems of non-uniform strain changes of point-type strain sensors, difficulty in ensuring absolute centering of the force of the force measuring ring, and affecting the accuracy of cable force monitoring. Long-term weather resistance, unique anti-electromagnetic interference ability, stable monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

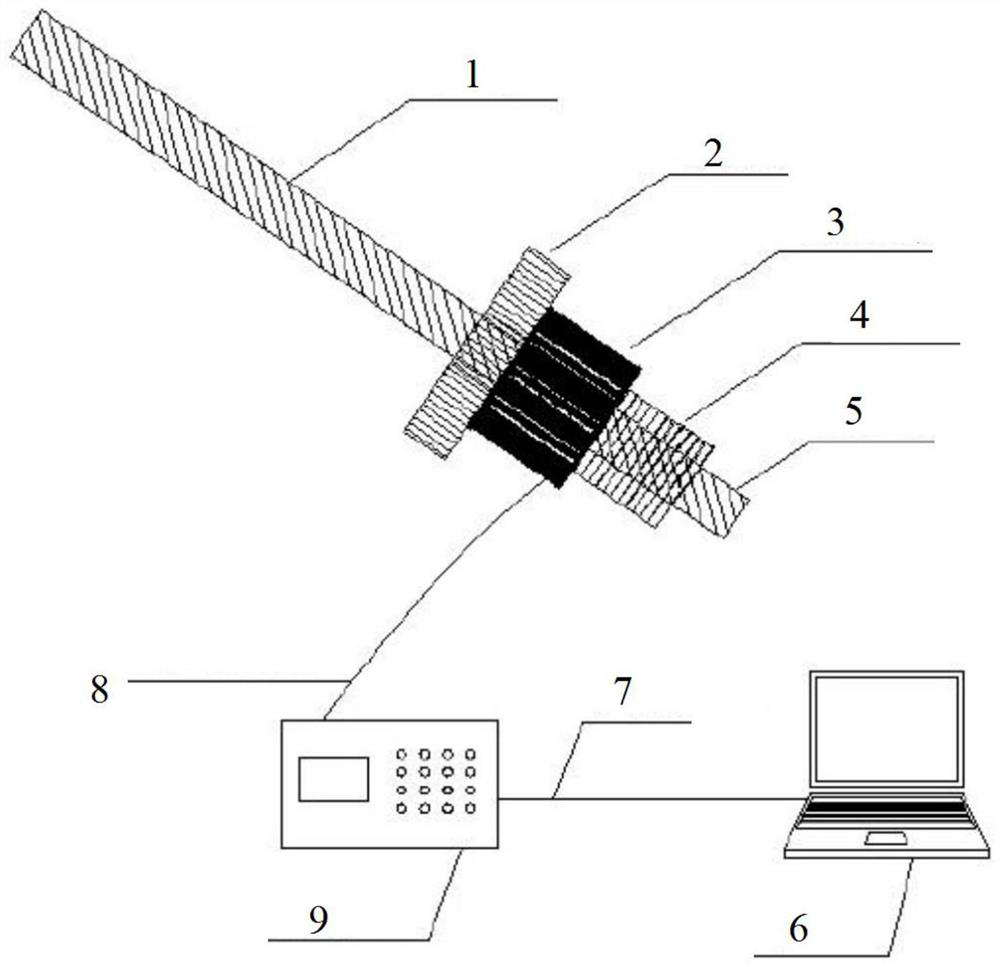

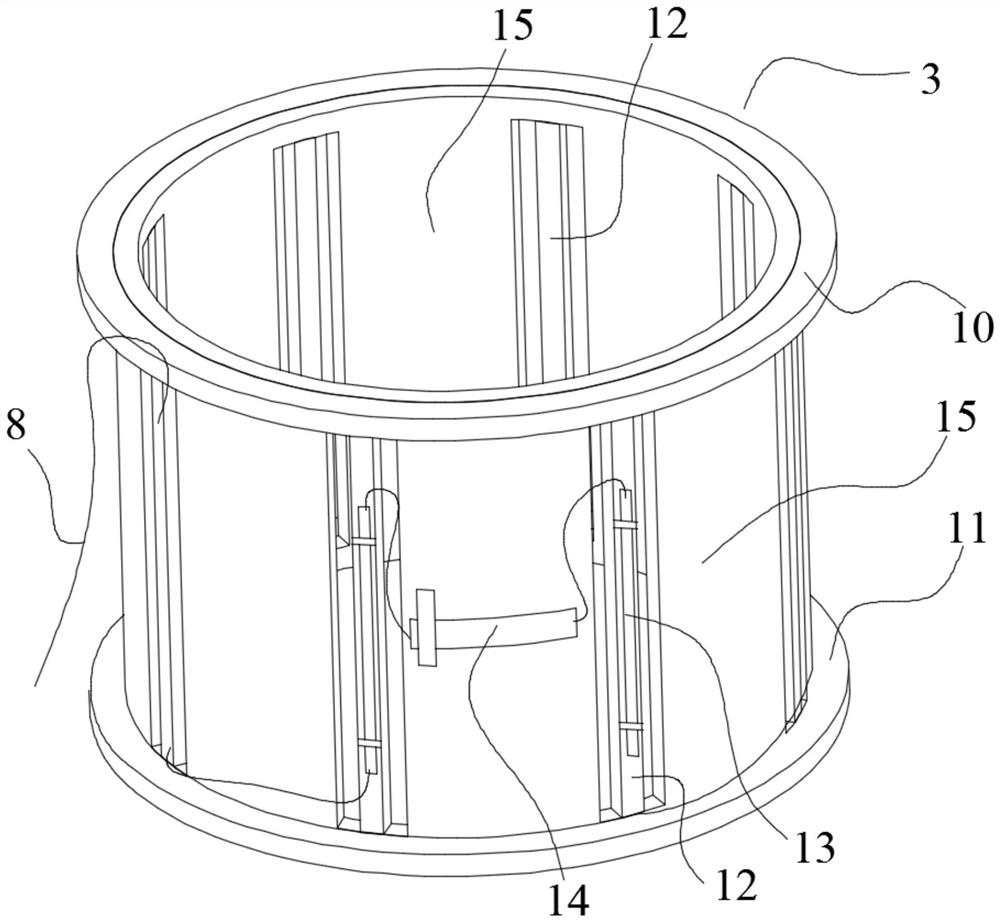

[0034] Such as figure 1 with figure 2As shown, a cable force real-time monitoring device includes a force-measuring ring 3 and eight long-gauge fiber grating strain sensors 13. The force-measuring ring 3 is a hollow ring, which includes a first force-bearing ring 10, a second Forced ring 11 and side wall 15 provide axial grooves on side wall 15 to form narrow columns 12 for installing sensors. In this embodiment, there are 8 narrow columns 12, and each narrow column 12 is installed One long-gauge fiber grating strain sensor 13 , generally more than four long-gauge fiber grating strain sensors 13 can obtain stable data. The long gauge fiber grating strain sensor 13 is firmly connected by cold light welding process, and measures the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com