Structure surface defect detection method based on high-frequency Lamb wave frequency domain information

A technology of structural surface and domain information, which is applied in the processing of detection response signals, measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, etc. Crack inefficiency and other problems, to achieve the effect of strong anti-noise ability, good engineering applicability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

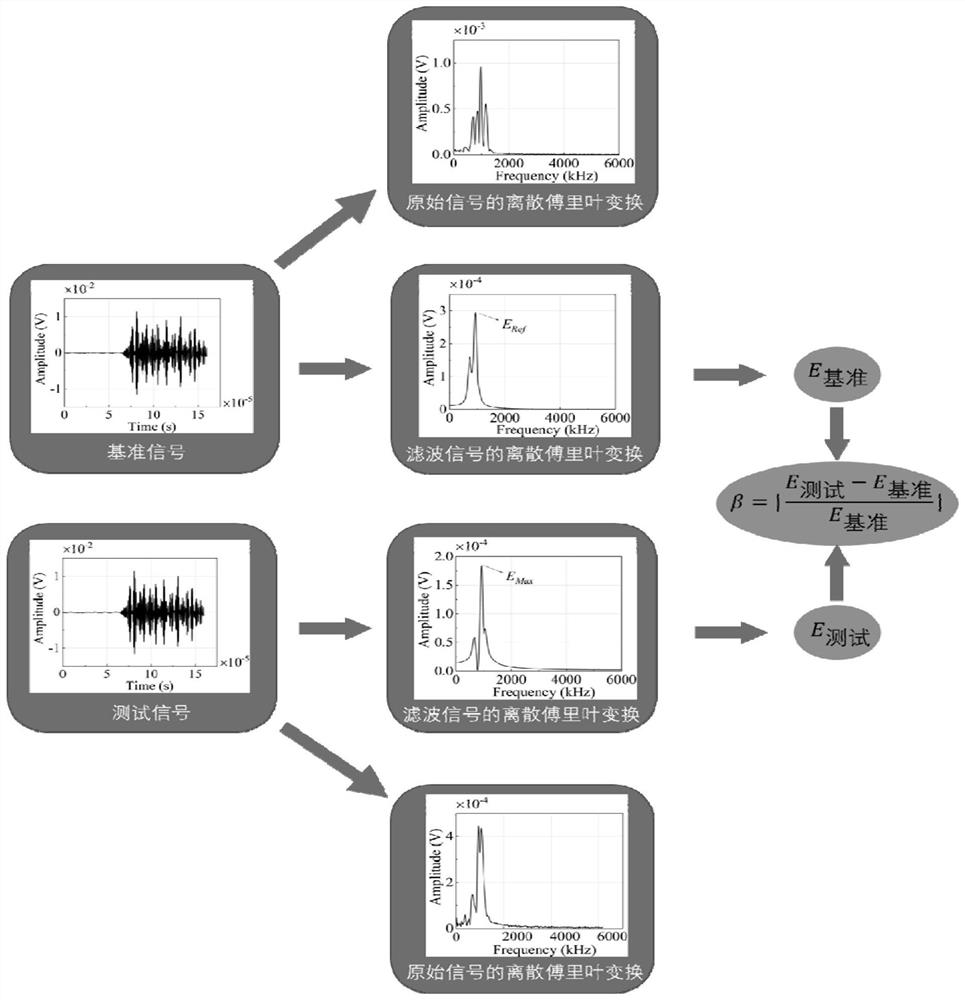

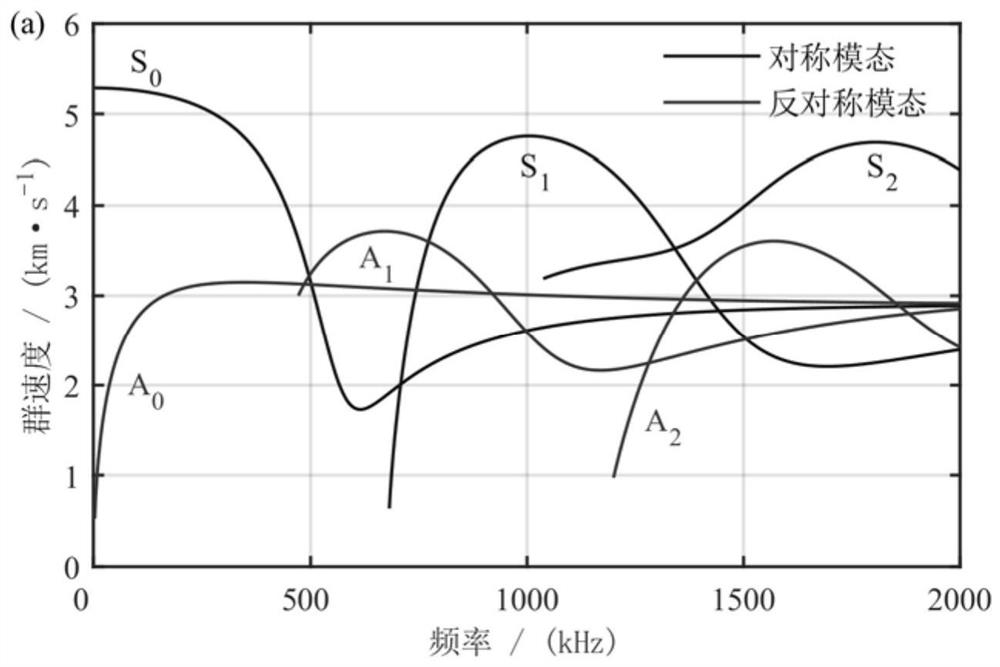

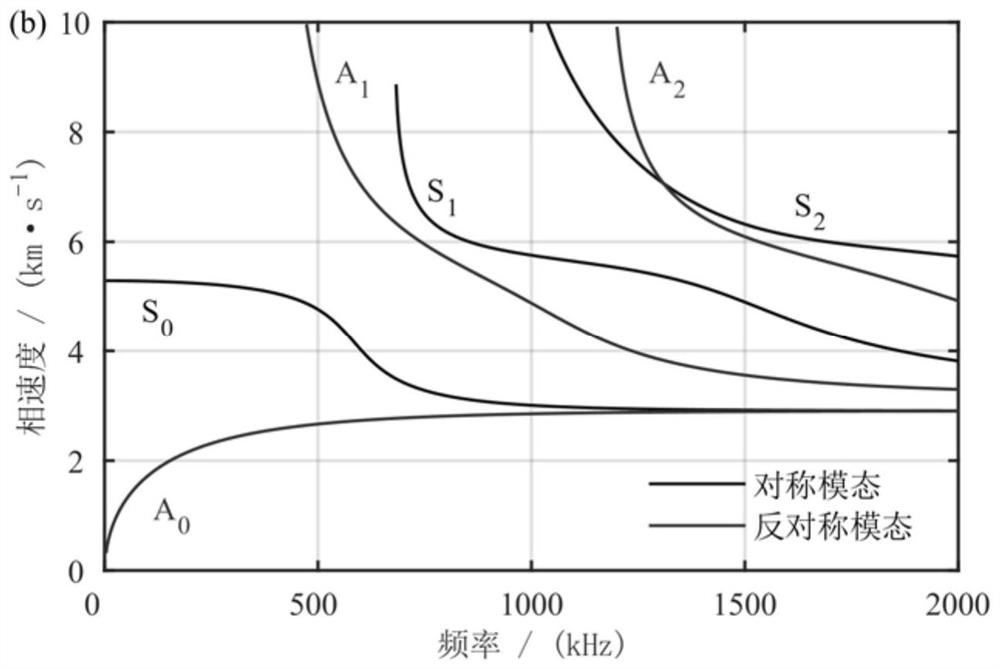

[0056] Taking the detection of surface defects of different depths in a 4mm steel plate as an example, the feasibility of the present invention for detecting surface defects and characterizing the depth of defects is verified. The theoretical basis of the present invention is the propagation mechanism of Lamb wave in the waveguide, and the method requires one or more exciters to apply excitation signals to activate the guided wave in the thin-walled structure so that it propagates on the free surface of the structure. Therefore, it is first necessary to solve the Lamb's dispersion equation in the 4mm steel plate, and determine the appropriate excitation frequency by analyzing the Lamb wave dispersion curve. Then the excitation signal is applied to the exciter in turn to obtain the corresponding received signal. Finally, the damage feature information is extracted, and the damage index is calculated according to the formula of β (formula (4)).

[0057] 1. Determine the excitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com