Self-propelled traction ship model control and measurement method

A measurement method and technology of towing ships, applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., to achieve the effect of accurate test data, easy operation and timely processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

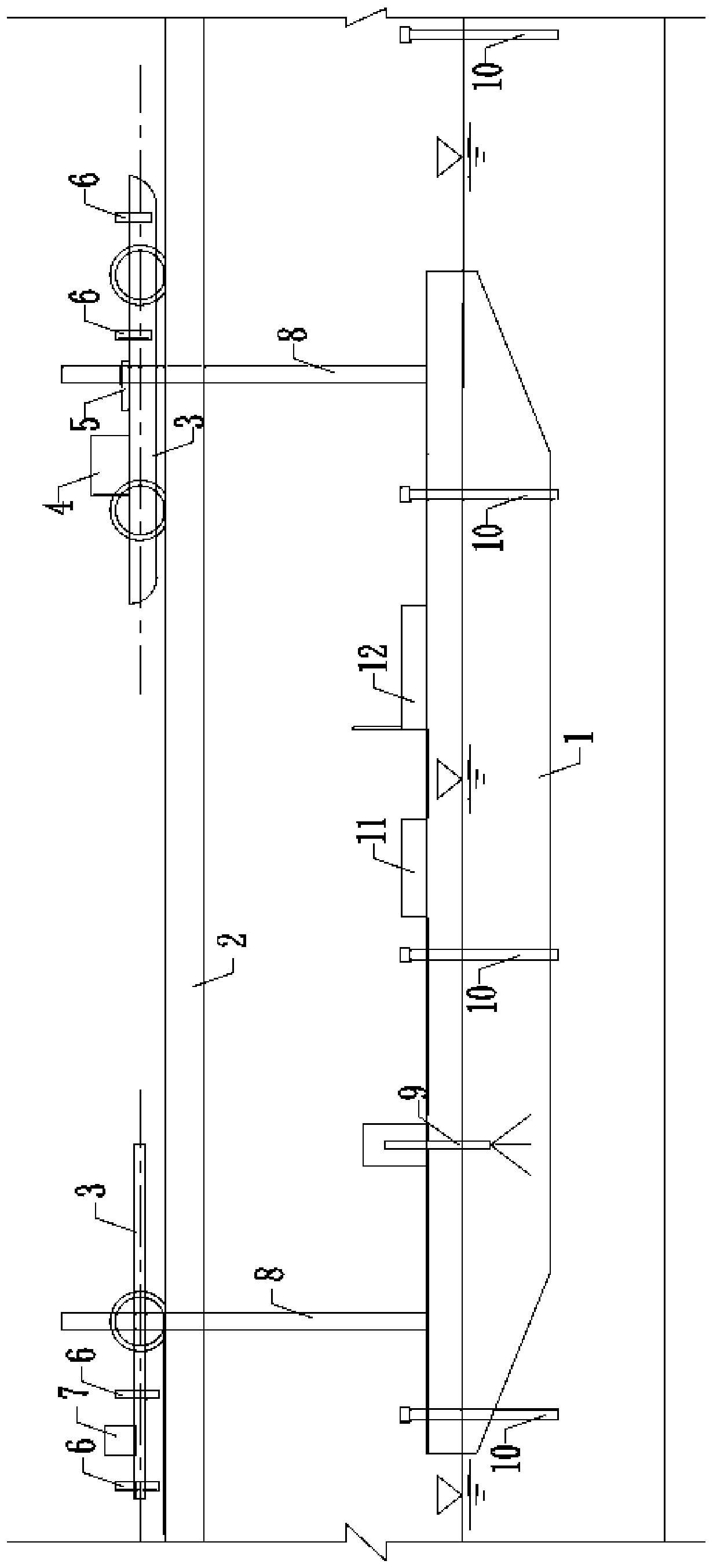

[0030] A device for towing a ship model, comprising: a guide rail 2, a ship model tractor 3, a drive motor 4 and a fixed rod 8;

[0031] Above-mentioned driving motor 4 is fixedly installed on the ship model tractor 3;

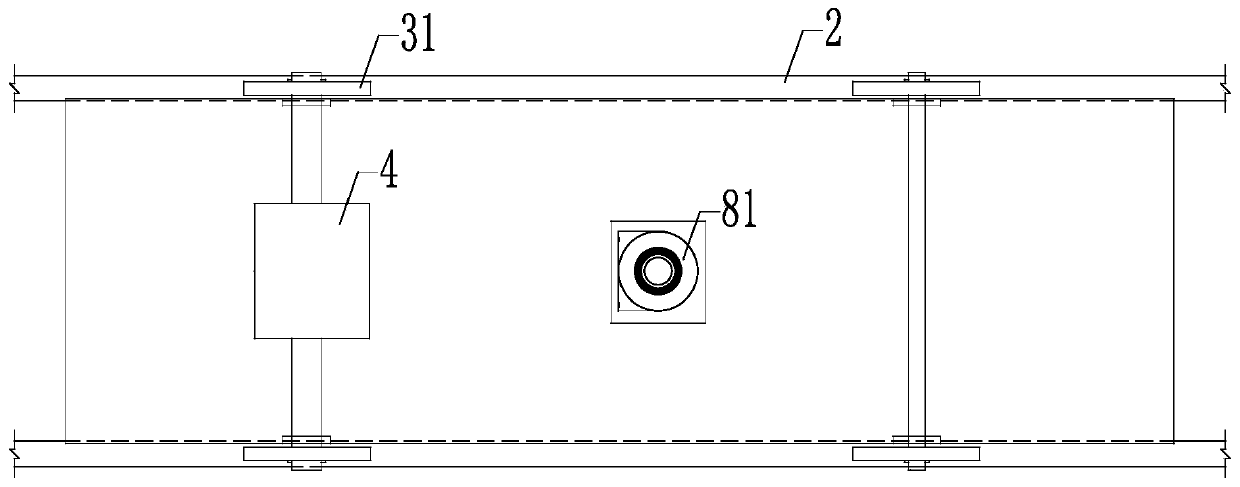

[0032] The driving wheel 31 of the above-mentioned ship model tractor 3 is fixed along the guide track 2, so that the ship model tractor 3 can only move forward and backward along the guide track 2;

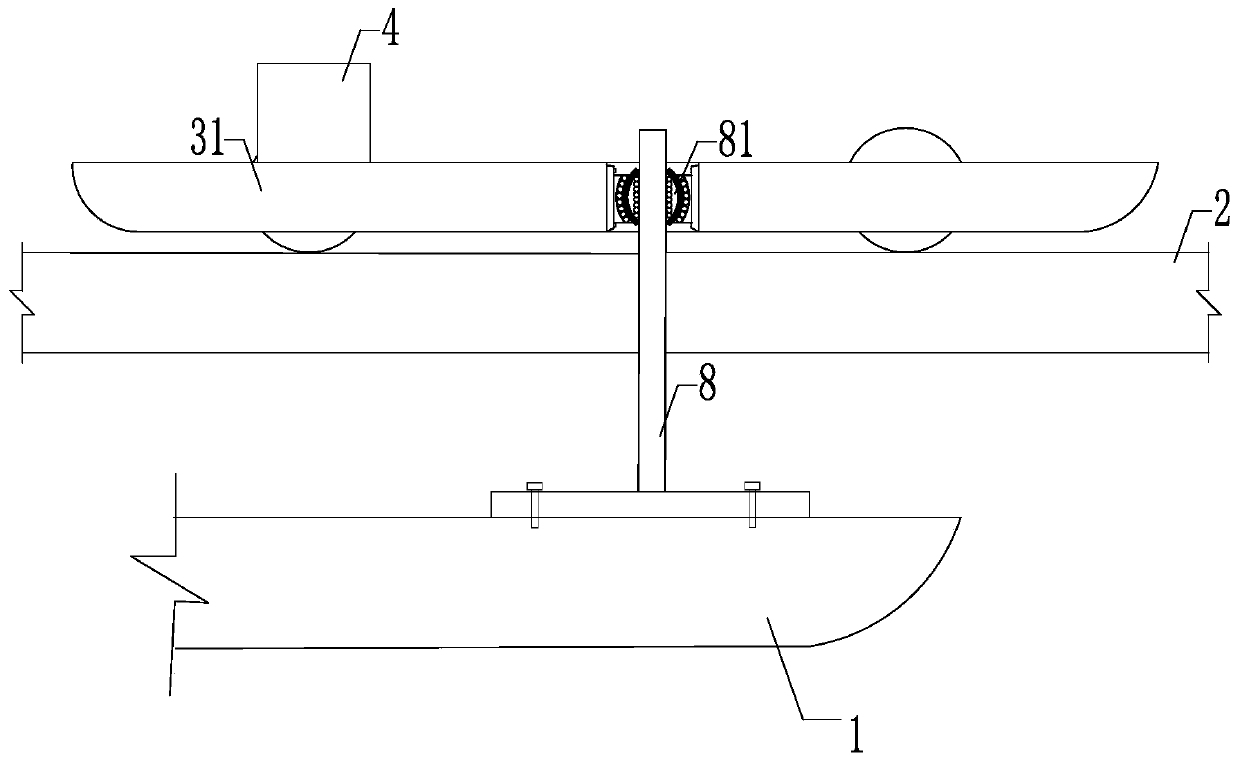

[0033] Above-mentioned ship model tractor 3 links to each other with ship model by fixed rod 8;

[0034] Above-mentioned fixed rod 8 is a cylindrical rod, passes through the middle hole of universal bearing 81 at one end of ship model tractor 3, fixed rod 8 can slide freely up and down in the middle hole of universal bearing 81, and universal bearing 81 is fixed on On the ship model tractor 3; so that the fixed rod 8 can move up and down in the vertical direction, when the fixed rod 8 is in a non-vertical state, it can still be kept consistent with the center ho...

Embodiment 2

[0039] In the ship lift project, in order to study the hydrodynamic conditions of ships entering and leaving the cabin, a local physical model of the cabin and approach channel with a scale of 1:12 was established, and a 3500t cargo ship was simulated by a traction ship model for testing.

[0040] Arranged as figure 1 As shown, the guide rail 2 is set above the ship model 1, the ship model tractor 3 is fixed on the guide rail 2, and the ship model is driven by the fixed rod 8. When the tester enters the relevant settings of the ship model on the ship model towing control system interface After parameters and control instructions, the ship model tractor 3 is driven by the drive motor 4 to drag the ship model 1 to move forward along the guide rail 2 . A laser range finder 7 is installed on the ship model tractor 3 to measure the sailing distance of the ship model, and then calculate the real-time speed of the ship model according to the sailing time of the ship model. Ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com