Defectoscope and mobile flaw detection source monitoring and management system formed by the defectoscope

A flaw detector, power management module technology, applied in manufacturing computing systems, radio wave measurement systems, satellite radio beacon positioning systems and other directions, can solve problems such as loss, flaw detectors are easily stolen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution provided by the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

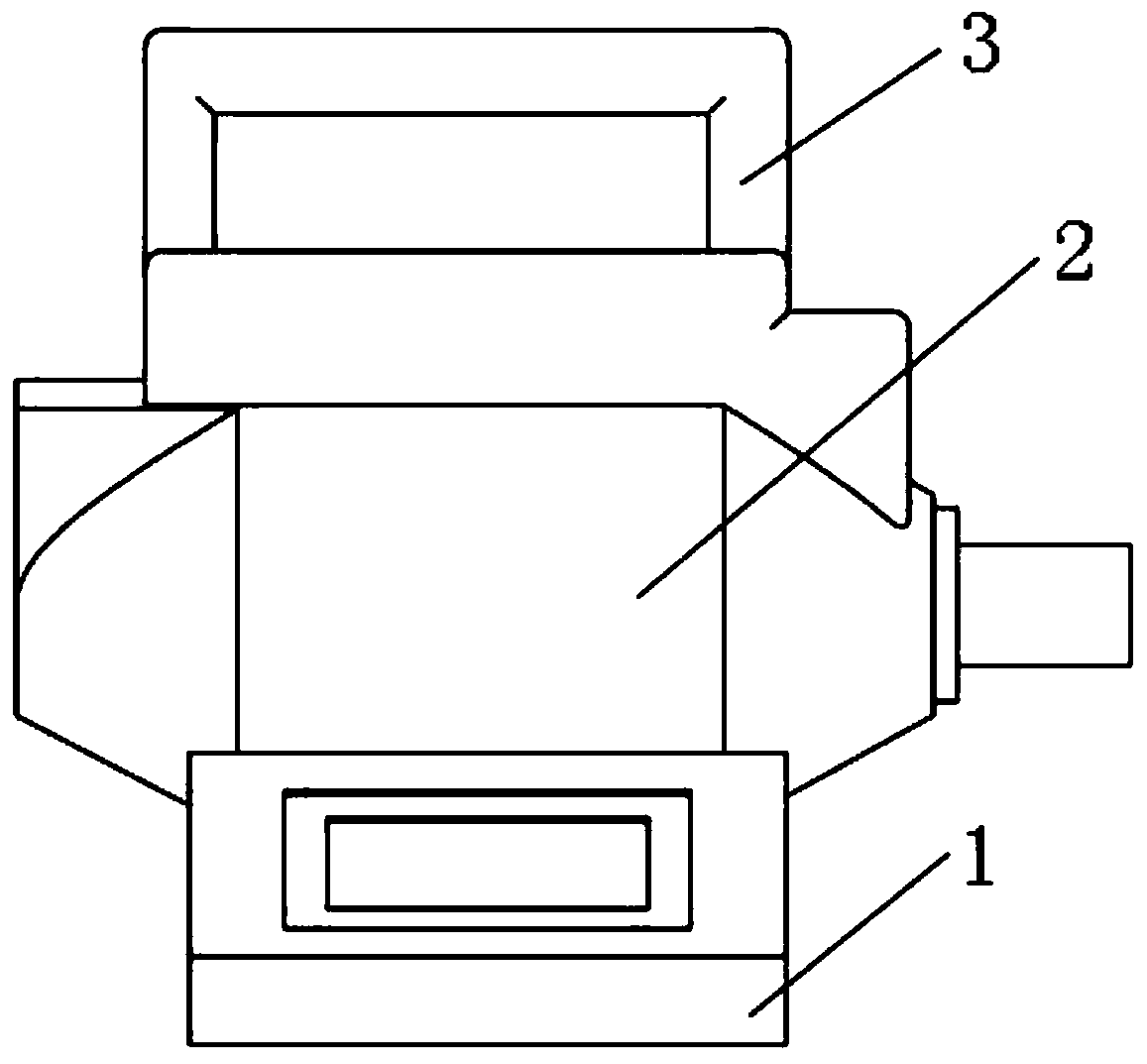

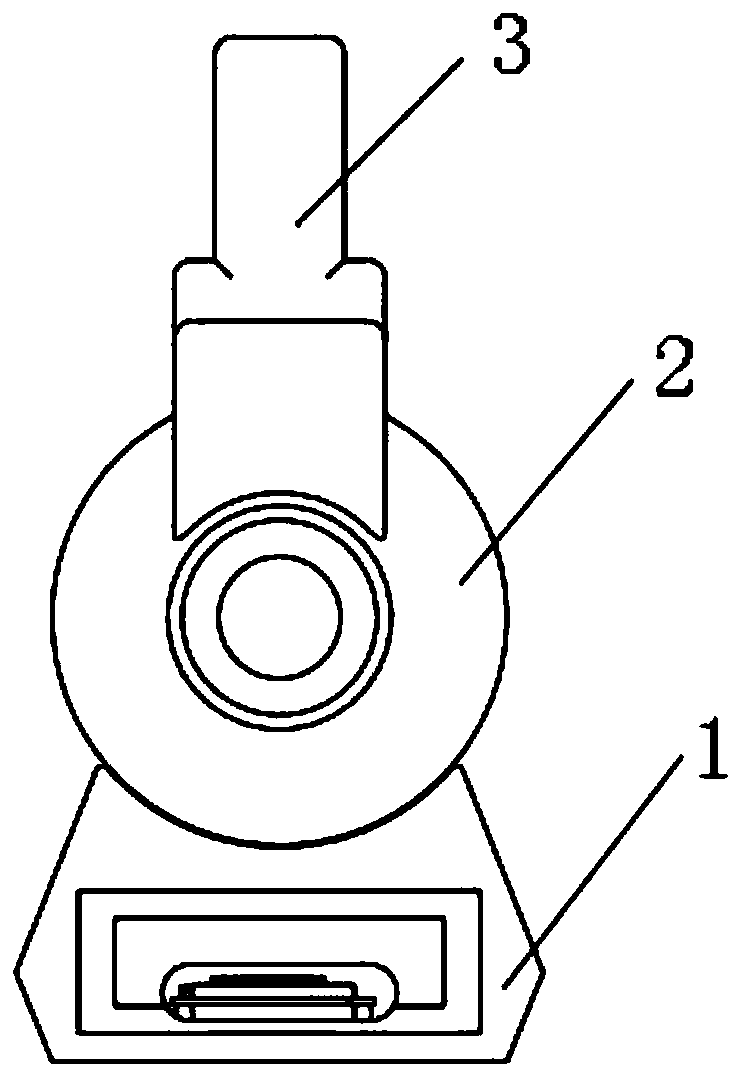

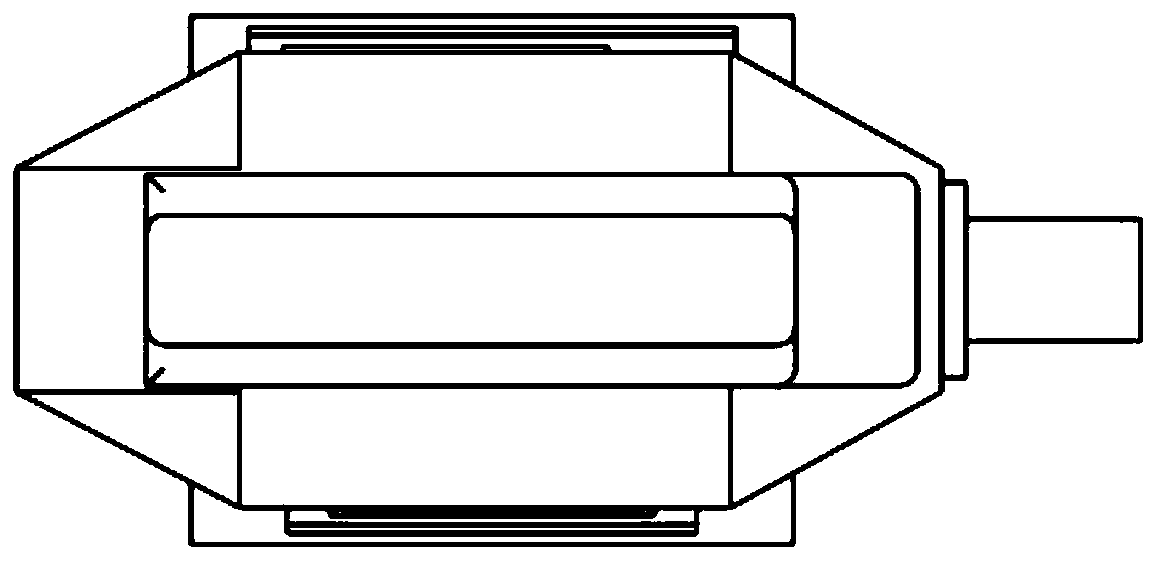

[0030] In order to solve the problem that the existing flaw detector is easy to be stolen and lost during transportation, storage and operation, the present invention provides a flaw detector with positioning function, such as Figure 1-4 As shown, the flaw detector provided by the present invention includes a housing 1 and a base 2 installed at the bottom of the housing 1. The housing 1 is provided with a radiation source outlet 11, a safety lock 12 and an automatic safety switch 13. The inside of the housing 1 Installed with uranium 14 and radioactive source 15. Such as Figure 5 As shown, the base 2 of the flaw detector includes a radiation detection module for judging whether the flaw detection source is in the flaw detector, a communication module for positioning and data information transmission, and a radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com