Precise clamping device and pre-tightening method for large-caliber laser transmission reflector

A technology of clamping device and mirror, applied in the directions of installation, optics, optical components, etc., to achieve the effect of good load sharing characteristics, ensure controllability, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and a specific implementation example.

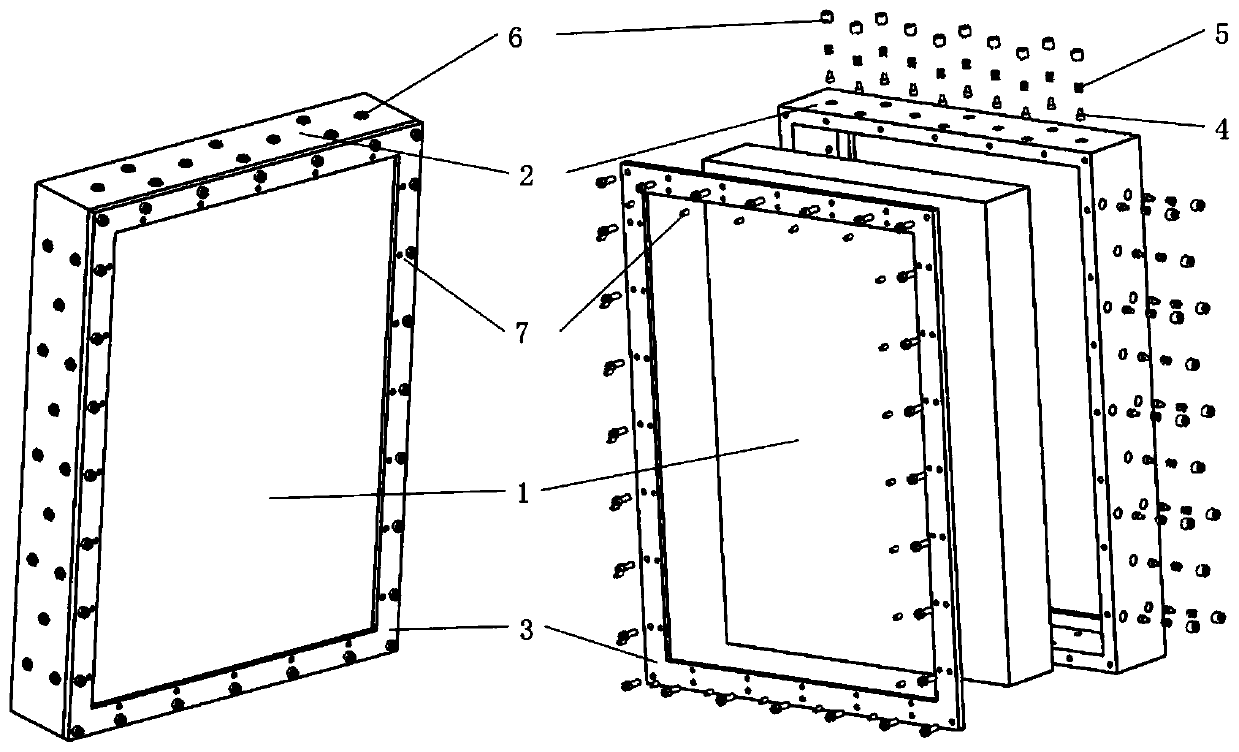

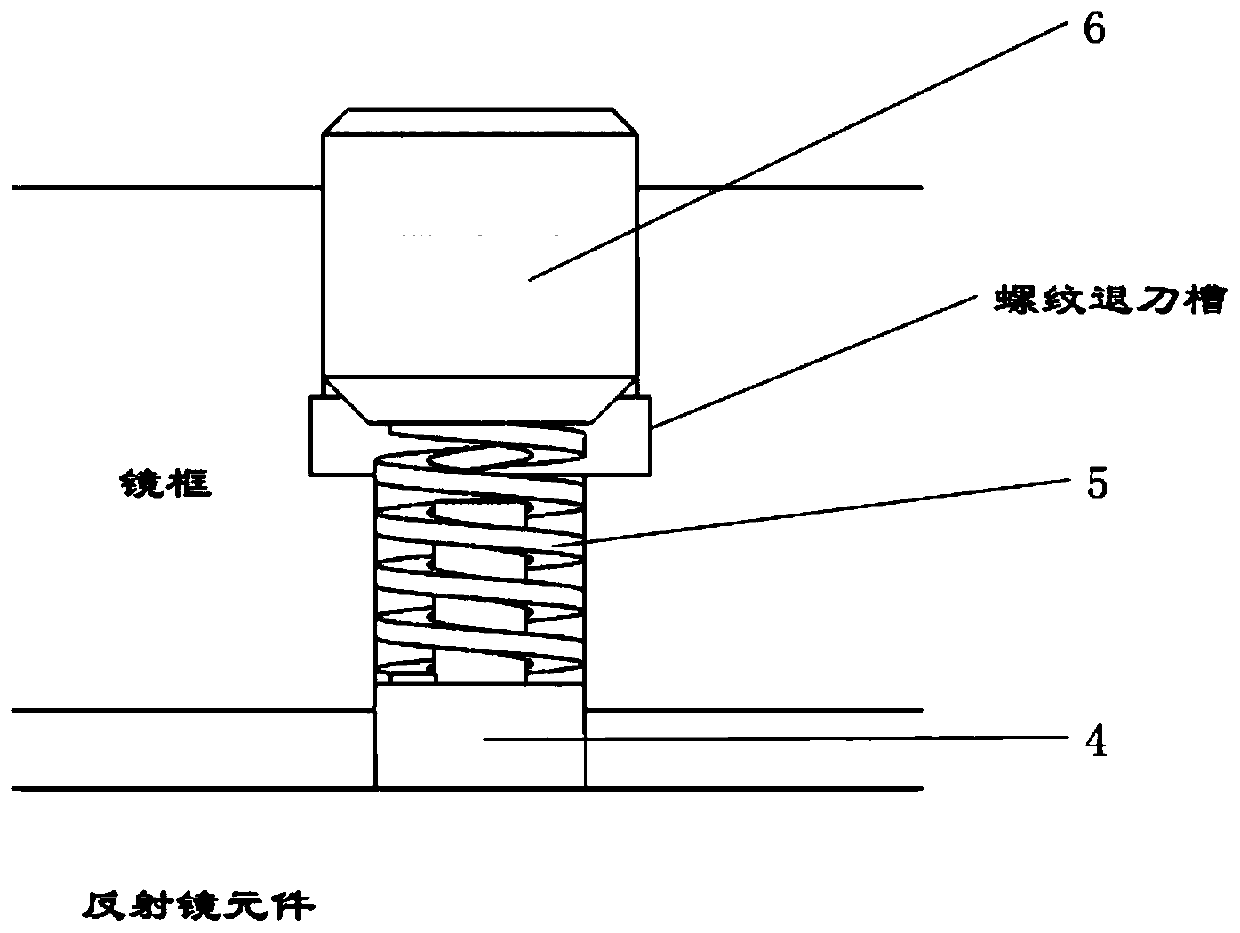

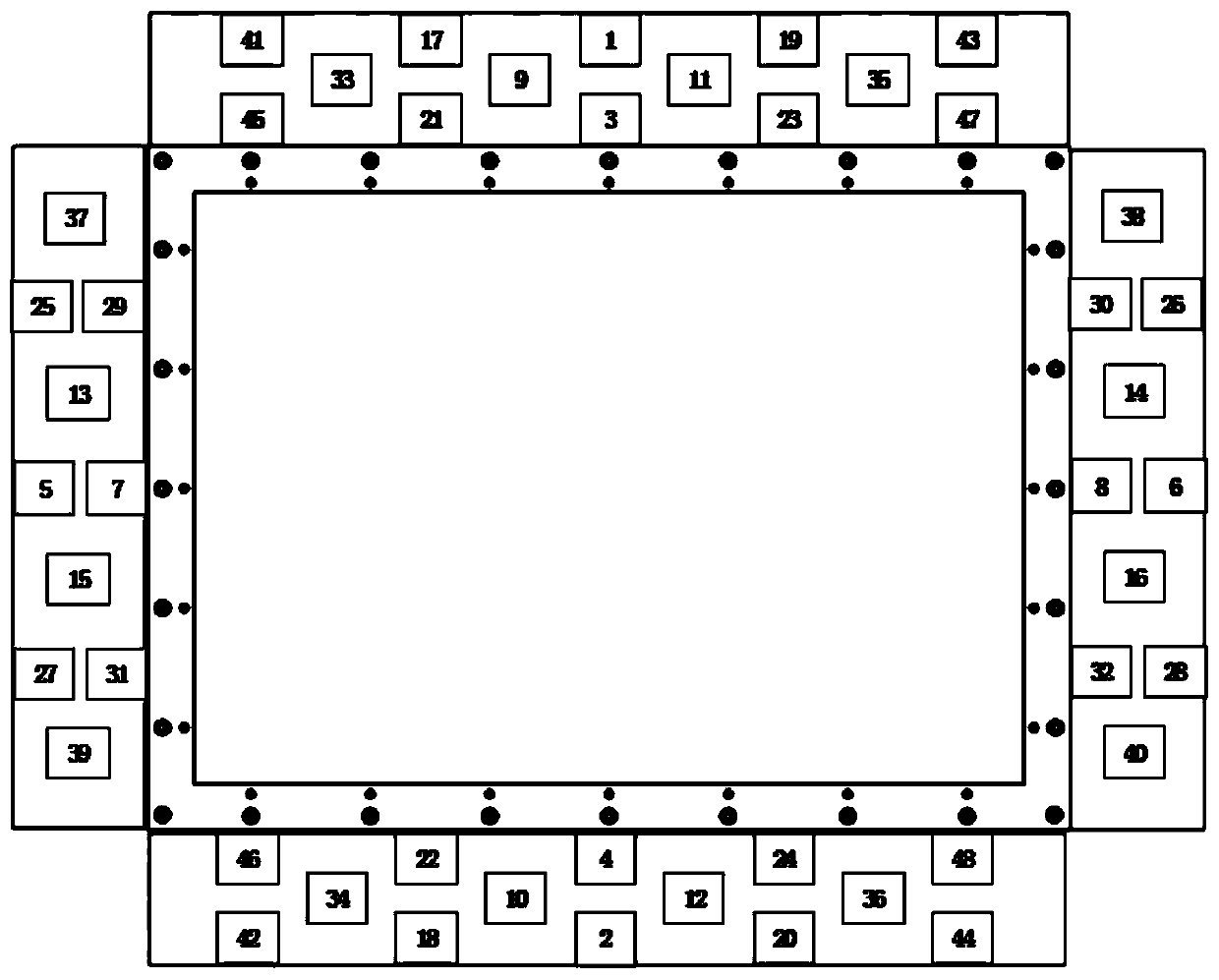

[0036] like figure 1 and figure 2 As shown, a precision clamping device for a large-diameter laser transmission mirror includes a mirror element 1, a mirror frame assembly 2, a mirror body pressure plate 3, a guide pad 4, a flexible element 5, a flat-end fine thread screw 6, and a rubber head screw 7 etc. The mirror frame assembly 2 is a rectangular frame body, used for installing and clamping the mirror element 1 . A total of 48 stepped holes are opened on its four sides, which are distributed in a triangular array, wherein the large holes are threaded holes, and the small holes are through holes. The threaded screw 6 is screwed into the threaded hole of the side wall to realize the pre-tightening of the mirror element 1 in the circumferential direction. There are 28 threaded holes in the front upper part of the mirror fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com