Preparation method of colored ink powder

A technology of color powder and toner, which is applied in the field of toner preparation, can solve the problems of thick printing layer, fast fading speed, wasting toner, etc., and achieve the effect of thin printing layer, strong adsorption force and high market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

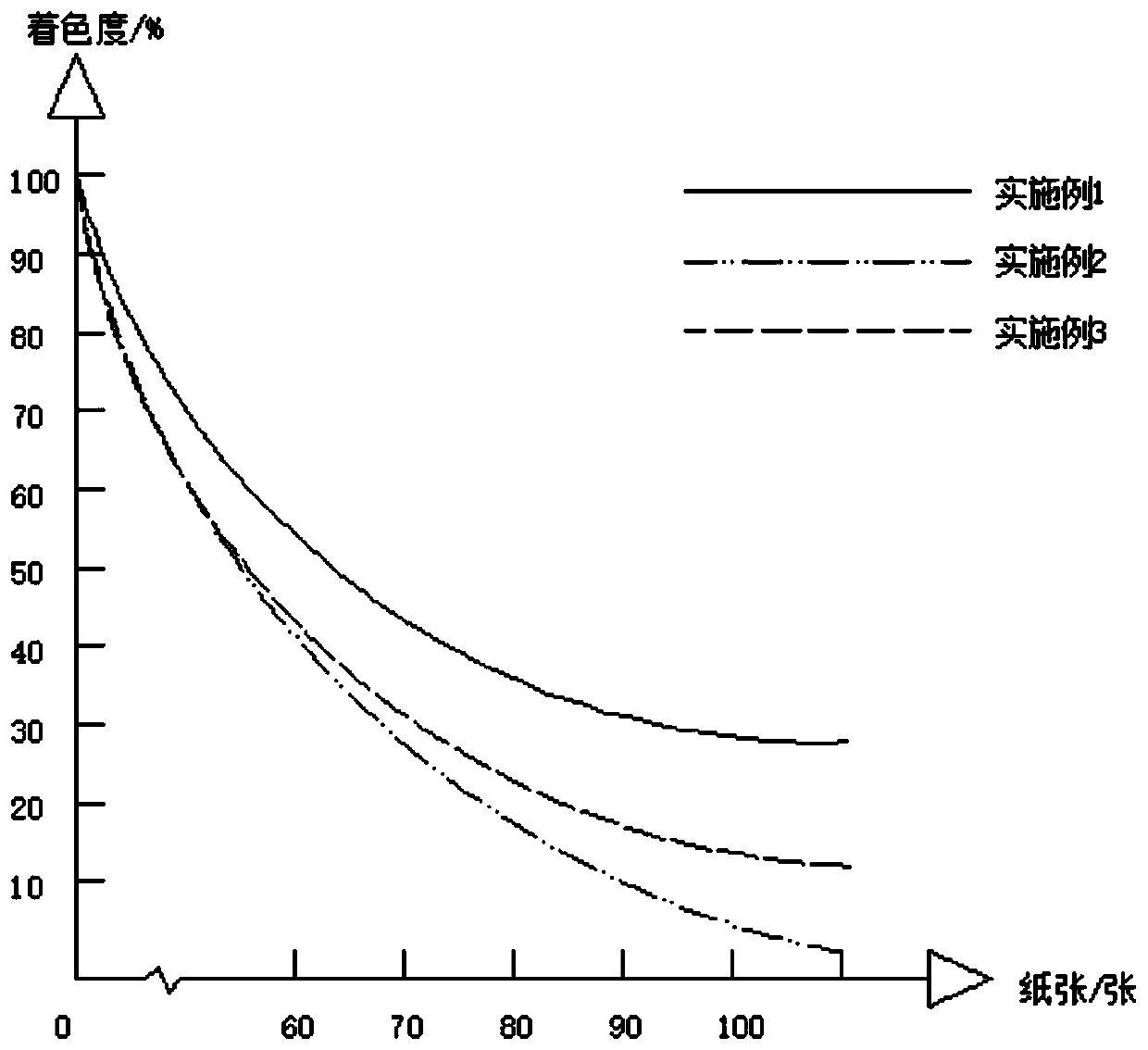

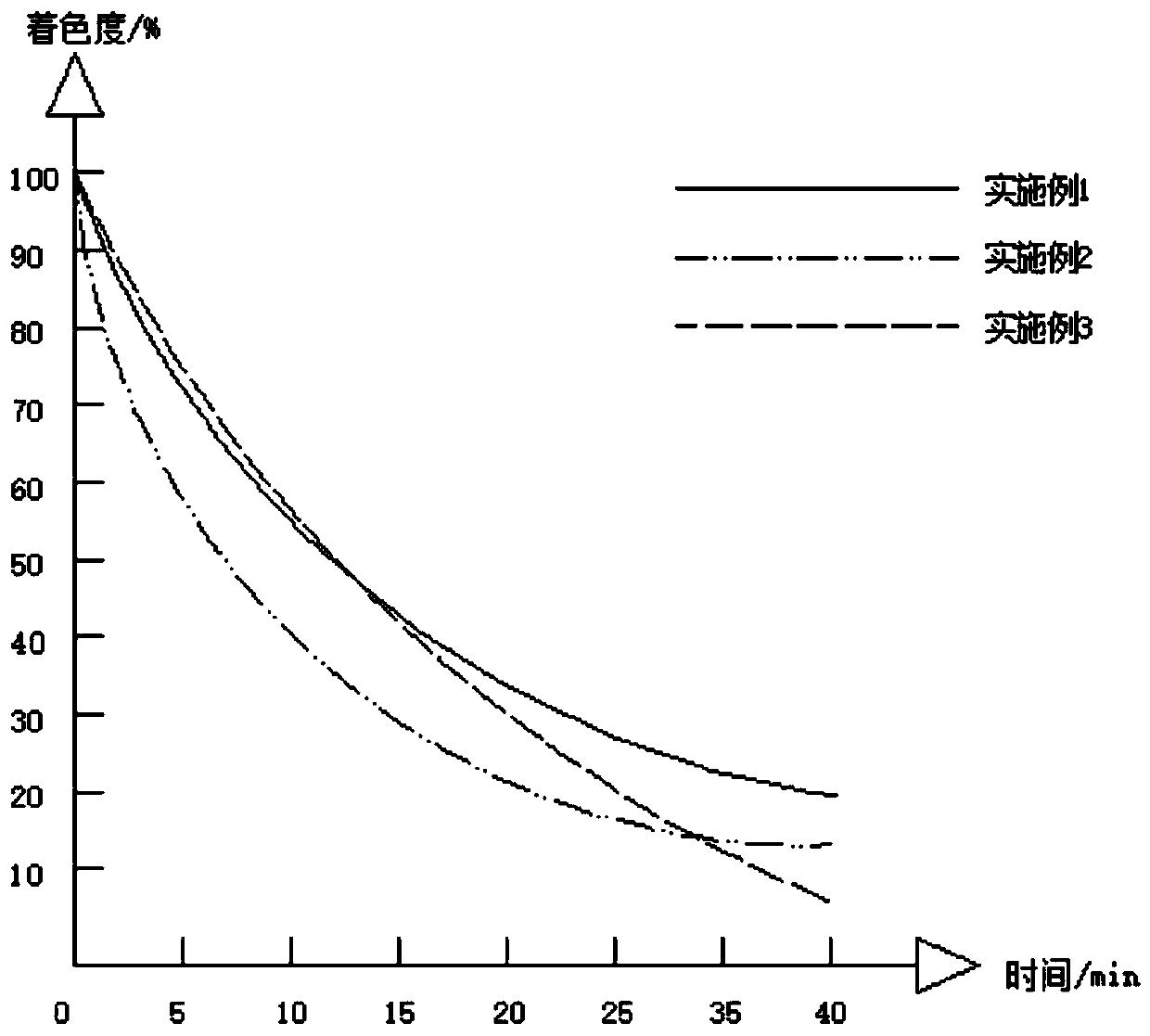

Examples

preparation example Construction

[0031] A preparation method of toner color powder, which is made of the following raw materials in parts by weight: 70-80 parts of polyester resin, 2-4 parts of organic black pigment, 2-4 parts of organic yellow pigment, and organic magenta pigment 3-5 parts, 2-3 parts of organic cyan pigment, 1-2 parts of additives.

[0032] The organic black pigment is carbon powder, the organic yellow pigment is pigment yellow 12, the organic magenta pigment is obtained by mixing pigment red 122 and pigment blue 60 in a ratio of 1:1, and the organic cyan pigment is pigment green 36 It is obtained by mixing with Pigment Blue 60 at a ratio of 1:1. The additive uses treated silica, and the treated silica includes one of the following: CAB-O-SIL TG-C321, CAB-O-SIL TG-C425, CAB-O-SIL TG-C493.

Embodiment 1

[0034] The invention discloses a preparation method of toner color powder, which is prepared from the following raw materials in parts by weight: 70 parts of polyester resin, 2 parts of organic black pigment, 2 parts of organic yellow pigment, and 3 parts of organic magenta pigment , 2 parts of organic cyan pigments, 1 part of additive, the additive adopts CAB-O-SIL TG-C321.

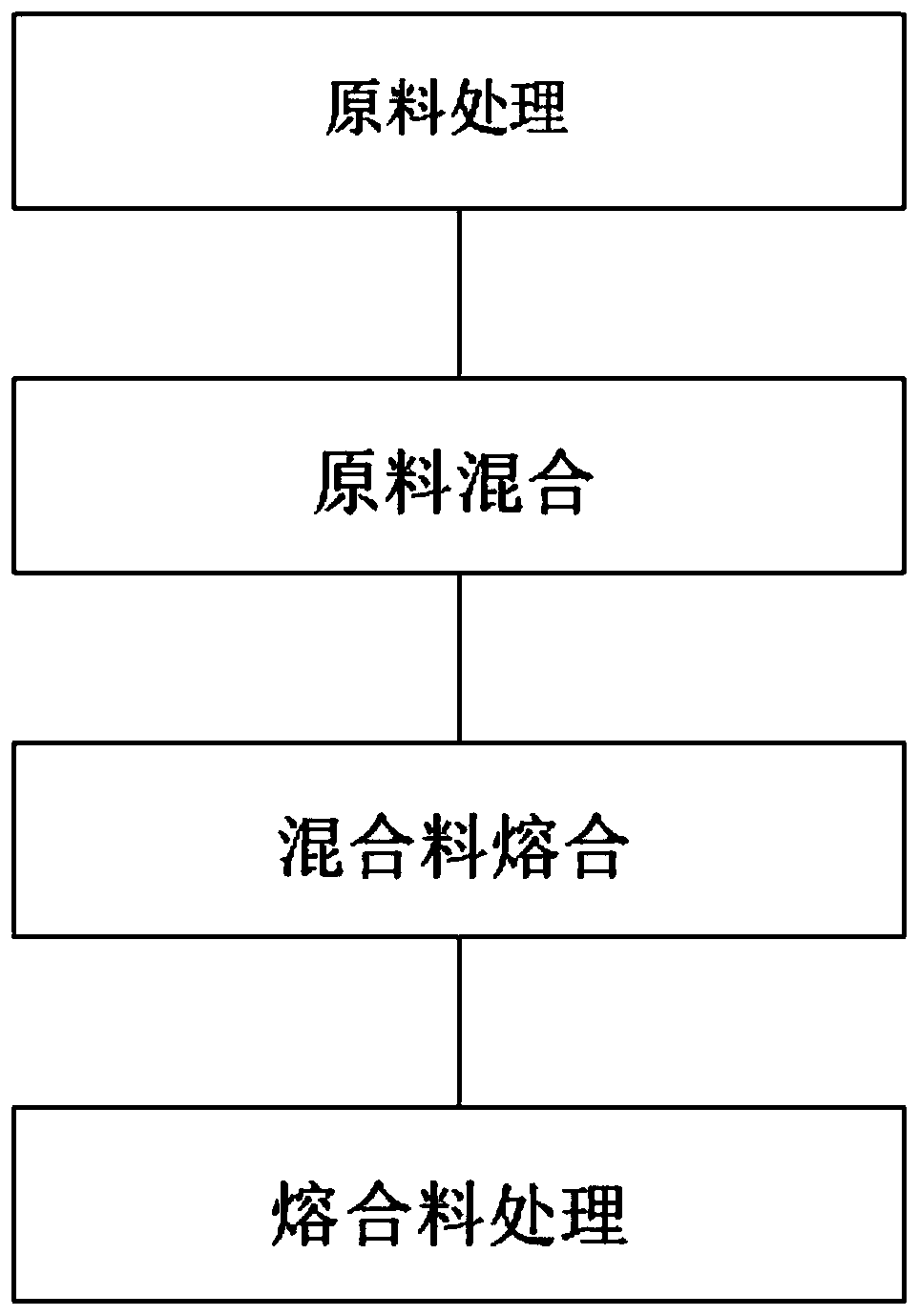

[0035] The preparation method of described toner color powder, concrete steps are as follows:

[0036] (1), raw material processing:

[0037] Pass polyester resin, organic black pigment, organic yellow pigment, organic magenta pigment, organic cyan pigment and additive through a 1000 mesh sieve;

[0038] (2), raw material mixing:

[0039] Add the screened polyester resin, organic black pigment, organic yellow pigment, organic magenta pigment, organic cyan pigment and additives into the mixer and stir;

[0040] (3) Mixture fusion:

[0041] Add the material produced by stirring and mixing in step (2) i...

Embodiment 2

[0049] The invention discloses a preparation method of toner color powder, which is prepared from the following raw materials in parts by weight: 75 parts of polyester resin, 3 parts of organic black pigment, 3 parts of organic yellow pigment, and 4 parts of organic magenta pigment , 2.5 parts of organic cyan pigments, 1.5 parts of additives, the additives are CAB-O-SIL TG-C425.

[0050] The preparation method of toner color powder, concrete steps are as follows:

[0051] (1), raw material processing:

[0052] Pass polyester resin, organic black pigment, organic yellow pigment, organic magenta pigment, organic cyan pigment and additive through a 1000 mesh sieve;

[0053] (2), raw material mixing:

[0054] Add the screened polyester resin, organic black pigment, organic yellow pigment, organic magenta pigment, organic cyan pigment and additives into the mixer and stir;

[0055] (3) Mixture fusion:

[0056] Add the material produced by stirring and mixing in step (2) into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com