Heating device and method for processing rolling edges on heating device

A heating device and rolling technology, which is applied in the direction of metal processing equipment, heating element shape, ohmic resistance heating parts, etc., can solve the problem of affecting the performance and aesthetics of the heating device, and the copper sleeve cannot be installed on the heated tube, copper sleeve Problems such as large gaps with the heated tubes, etc., to avoid the effects of performance and aesthetics, improve convenience, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

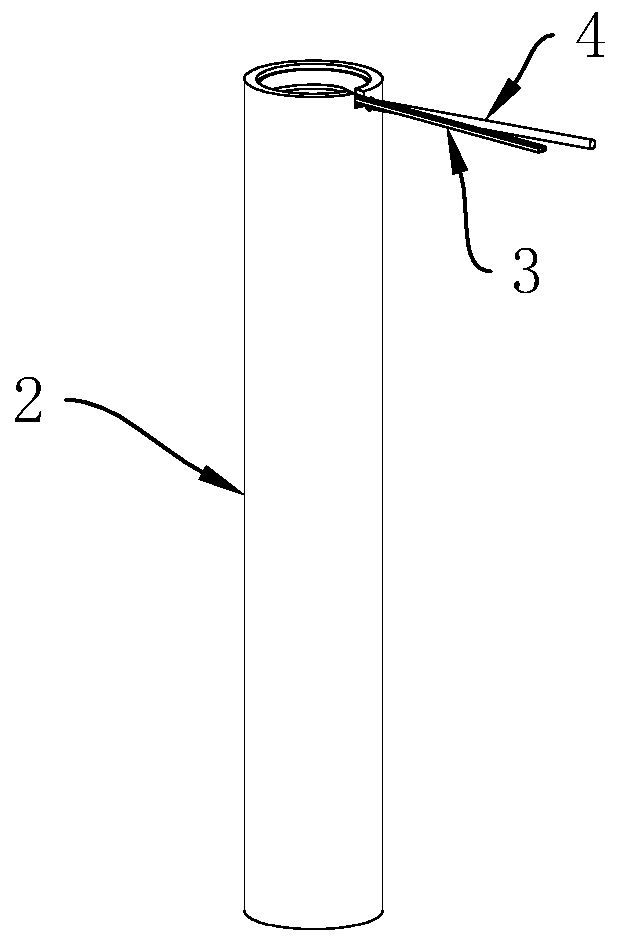

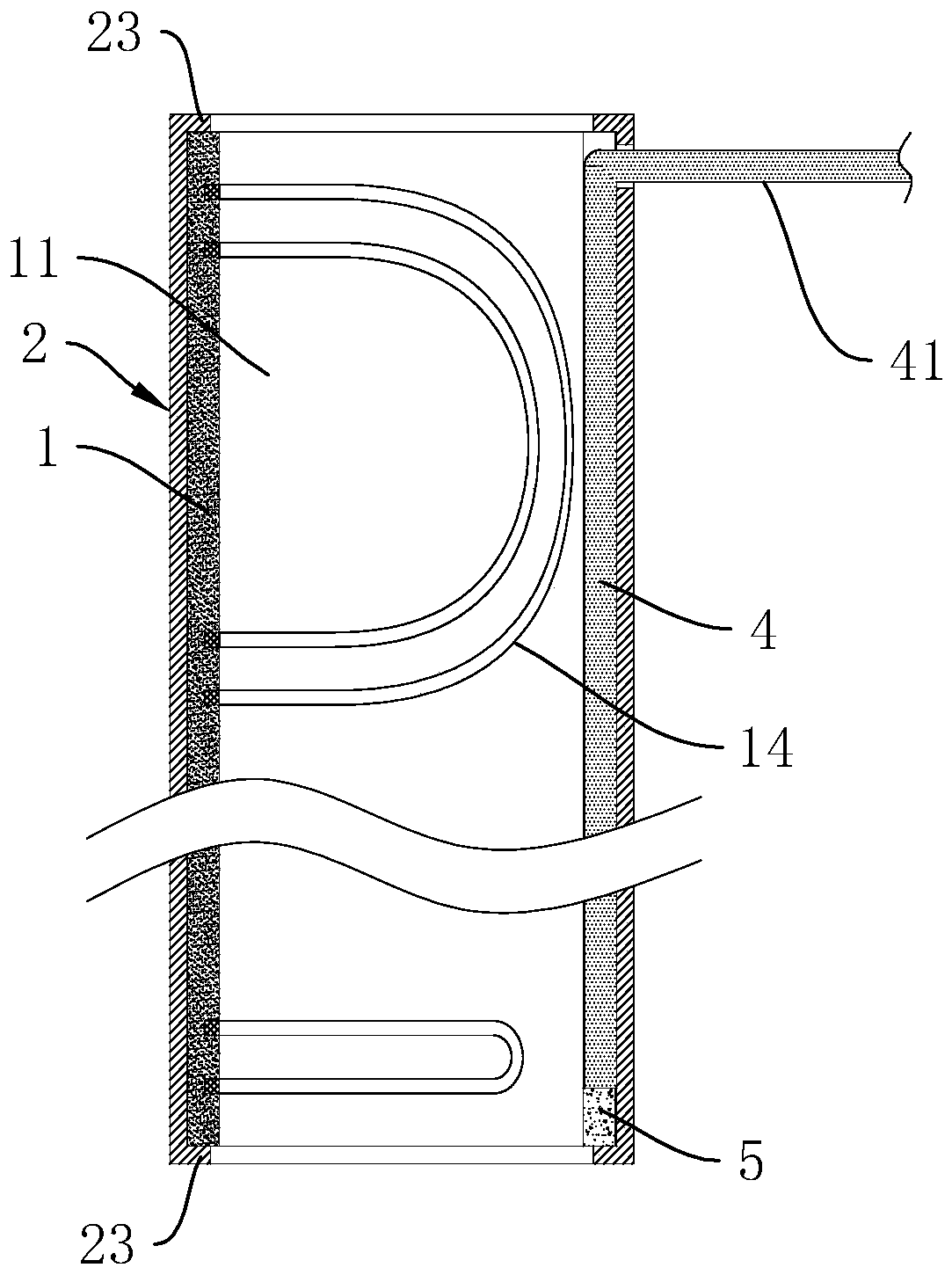

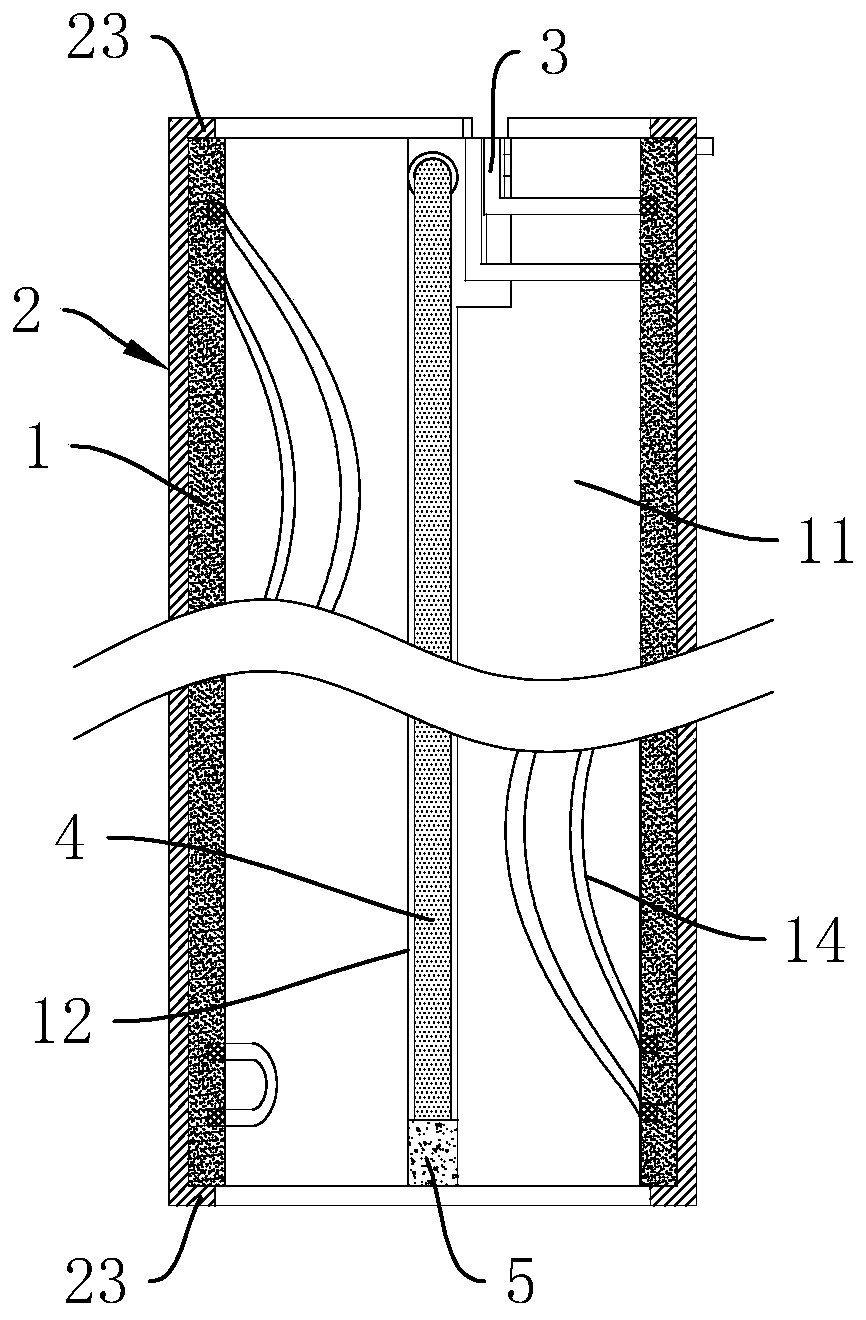

[0029] like figure 1 and figure 2 As shown, a heating device according to the present invention includes an inner copper sleeve 1, an outer steel cylinder 2, an electric heating wire 3, a temperature measuring wire 4, and a limit block 5, wherein, as figure 2 , Figure 4 , Figure 6 to Figure 8 As shown, the inner copper sleeve 1 is a tubular structure, and the inner hole of the inner copper sleeve 1 is a sleeve hole 11, and the outer surface of the inner copper sleeve 1 is provided with an expansion joint 12 penetrating to the sleeve hole 11, and The expansion joint 12 is extended to the two end faces of the inner copper sleeve 1, and the outer surface of the inner copper sleeve 1 is also provided with an inner relief hole 13 penetrating to the fitting hole 11, and the hole wall of the fitting hole 11 There is a surrounding wire groove 14 embedded with a power supply heating wire 3, and the initial groove end 141 and the terminal groove end 142 of the surrounding wire gr...

Embodiment 2

[0039] A method for processing rolling edges on the above-mentioned heating device, the method requires the following components: a rotating chuck 10, a reinforcing mandrel 20, and a rolling die 30;

[0040] first step, such as Figure 9 As shown, the inner copper sleeve 1 and the outer steel cylinder 2 of the suit are ready to be completed, and the end faces of both ends of the outer steel cylinder 2 exceed the end faces of the inner copper sleeve 1, and the two ends of the outer steel cylinder 2 exceed the inner copper sleeve 1 The parts constitute the convex ring part 101 respectively, and the axial length of the convex ring part 101 is smaller than the thickness of the inner copper sleeve 1;

[0041] The second step, such as Figure 9 As shown, the reinforcing mandrel 20 is inserted into the sleeve hole 11, and the end face of the reinforcing mandrel 20 is flush with the end face of the inner copper sleeve 1;

[0042] The third step, such as Figure 9 As shown, clamp th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com