Dust-free stone crushing and shaping system and method

A crushing system and dust removal system technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as pollution, incomplete treatment of dust, loud noise and dust, and reduce noise pollution. health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

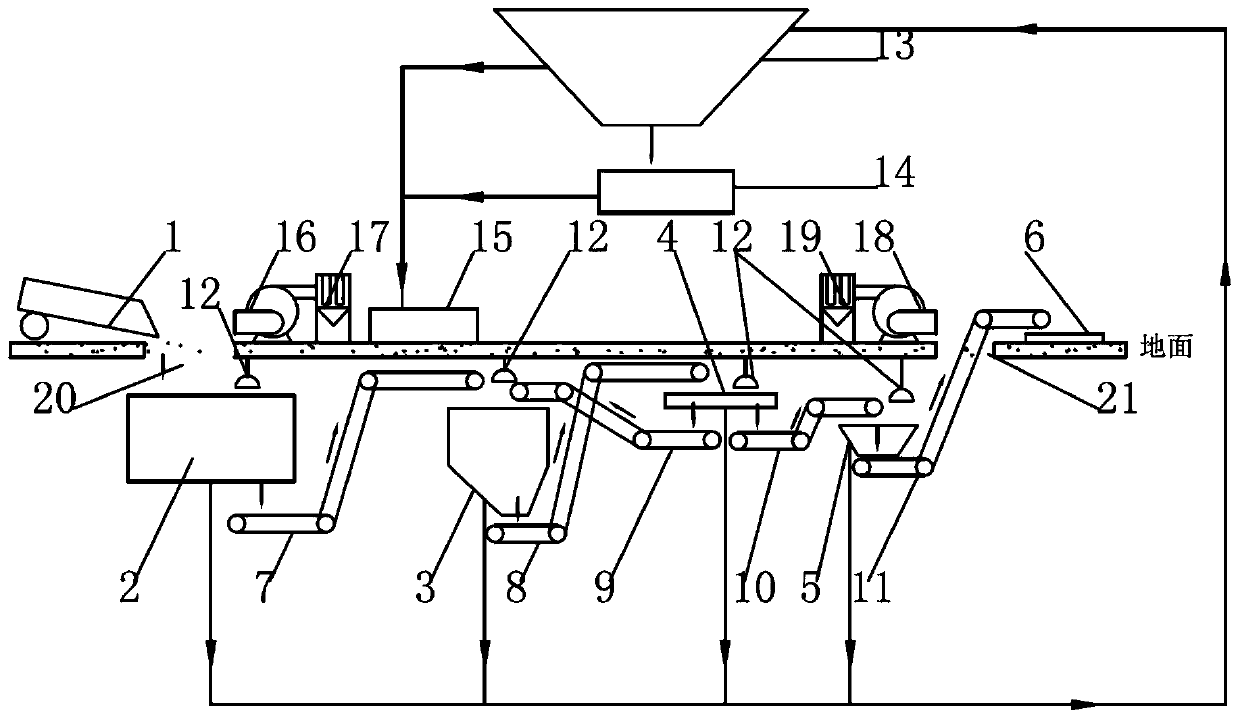

[0055] The large-grained stones are put into the primary crushing device 2 through the discharge channel of the feeder 1 through the discharge port 20 for primary crushing processing, and the stones processed by the primary crushing device 2 are transported to the fine crushing device 3 through the fine crushing feeding belt 7 After further processing by the fine crushing device 3, more uniform stones are transported to the vibrating screen 4 by the vibrating screen feeding belt 8, and the qualified stones with a particle size of ≤ 20mm are transported to the sand washing device by the sand washing device feeding belt 10 5 Carry out sand washing treatment, unqualified stones with a particle size > 20mm are transported to the fine crushing device 3 for reprocessing by the fine crushing return belt 9, and the sand washed stones are transported to the finished product by the finished product feeding belt 11 through the discharge port 21 Storehouse 6 completes the entire stone crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com