Method for preparing fe-al-ta multifunctional integrated material by Bridgman directional solidification technology

A fe-al-ta, directional solidification technology, applied in the field of metallurgy, can solve the problems of low utilization rate, single performance, single material performance, etc., and achieve the effect of prolonging service life and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

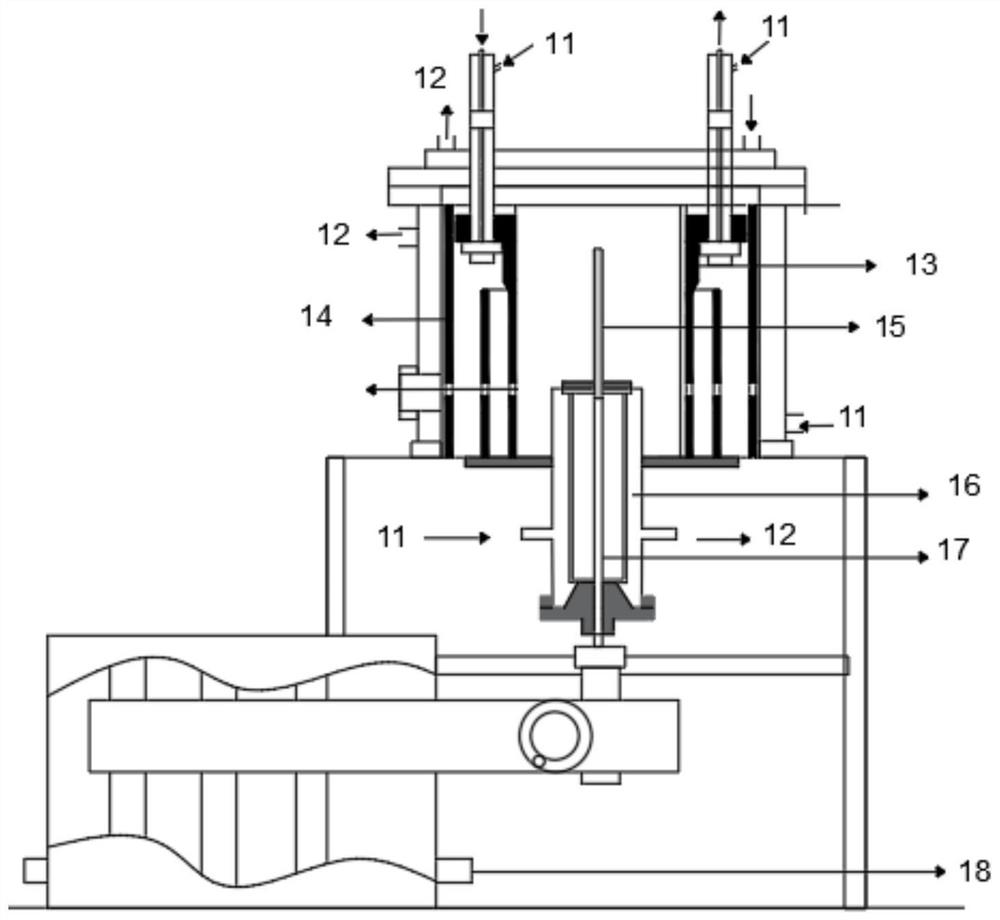

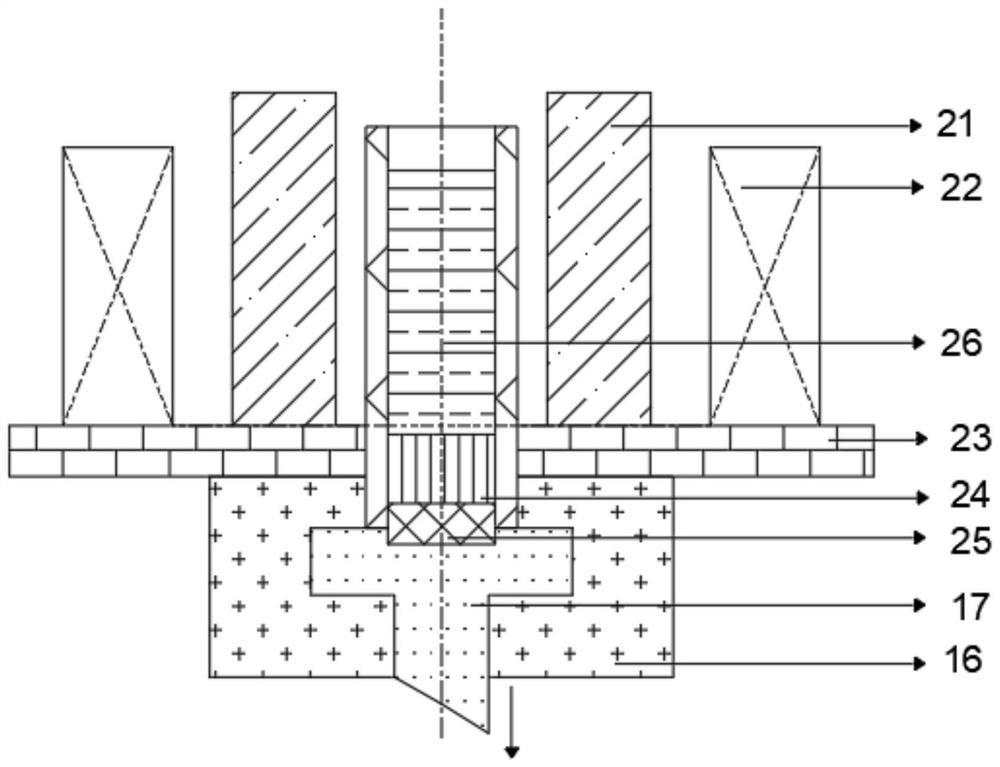

[0040] 1) Fix the corundum tube on the draw rod, and then put the wire-cut test bar into it, ensuring that the corundum tube and the test bar are in the center of the graphite sleeve. Turn on the mechanical pump and molecular pump in turn to vacuum until the vacuum degree is 4.0×10 -2 At Pa, the heating power is adjusted step by step to 2.5Kw, 5Kw and 7Kw. During heating, the molecular pump and mechanical pump are turned off when the composite vacuum count drops to 0. After heating for 20 minutes, the pumping rate and stroke (pumping The pulling rate is the rate at which the sample moves downward into the cooling liquid, such as 6μm / s; the pulling stroke refers to the distance of downward movement) for pulling. Turn off the heating power after the drawing is finished, and the circulating water can be turned off after 30 minutes to cool down with the furnace. After 90 minutes, the directional solidified sample can be taken out of the furnace after it is completely cooled.

[0041]...

Embodiment 2

[0043] 1) Fix the corundum tube on the draw rod, and then put the wire-cut test bar into it, ensuring that the corundum tube and the test bar are in the center of the graphite sleeve. Turn on the mechanical pump and molecular pump in turn to vacuum until the vacuum degree is 4.0×10 -2 At Pa, the heating power is adjusted step by step to 2.5Kw, 5Kw and 7Kw. During heating, the molecular pump and mechanical pump are turned off when the composite vacuum count drops to 0. After heating for 20 minutes, the pump will be pumped according to the set drawing rate and drawing stroke. Pull. Turn off the heating power after the drawing is completed, and the circulating water can be turned off after 30 minutes to cool down with the furnace. After 90 minutes, the directional solidified sample can be taken out of the furnace after it is completely cooled.

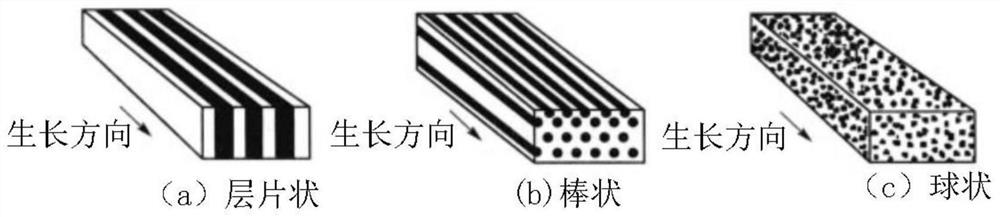

[0044] 2) When the material is in service and requires excellent properties such as plasticity, toughness and fatigue resistance, it is dir...

Embodiment 3

[0046] 1) Fix the corundum tube on the draw rod, and then put the wire-cut test bar into it, ensuring that the corundum tube and the test bar are in the center of the graphite sleeve. Turn on the mechanical pump and molecular pump in turn to vacuum until the vacuum degree is 4.0×10 -2 At Pa, the heating power is adjusted step by step to 2.5Kw, 5Kw and 7Kw. During heating, the molecular pump and mechanical pump are turned off when the composite vacuum count drops to 0. After heating for 20 minutes, the pump will be pumped according to the set drawing rate and drawing stroke. Pull. Turn off the heating power after the drawing is finished, and the circulating water can be turned off after 30 minutes to cool down with the furnace. After 90 minutes, the directional solidified sample can be taken out of the furnace after it is completely cooled.

[0047] 2) When the material is in service and requires good wear resistance and strength, it is directional solidified from bottom to top at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com