Double-welding-torch intelligent welding system

A welding system and dual torch technology, applied in welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems of low welding torch positioning accuracy, low welding quality, and high cost, and achieve the effect of facilitating later maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

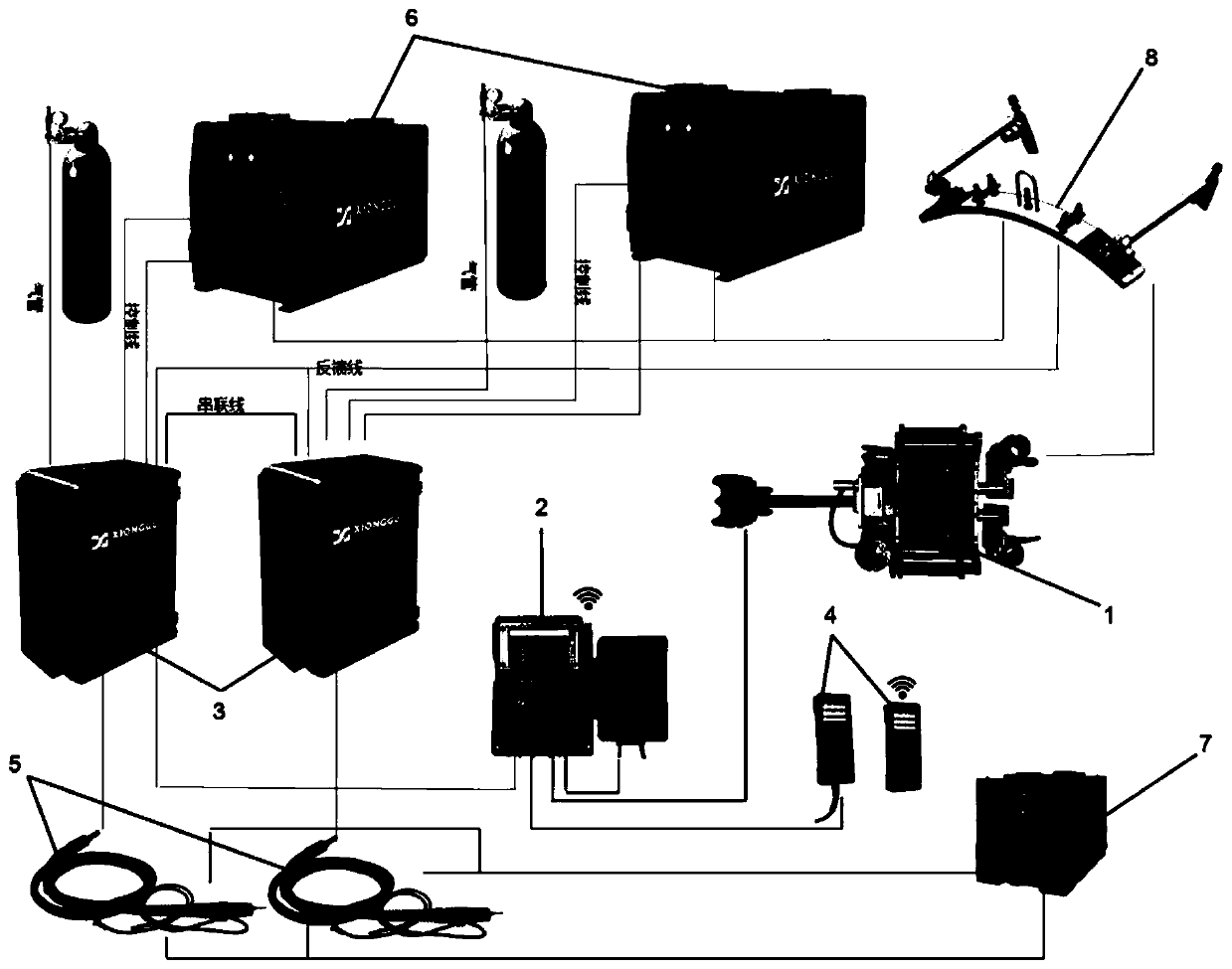

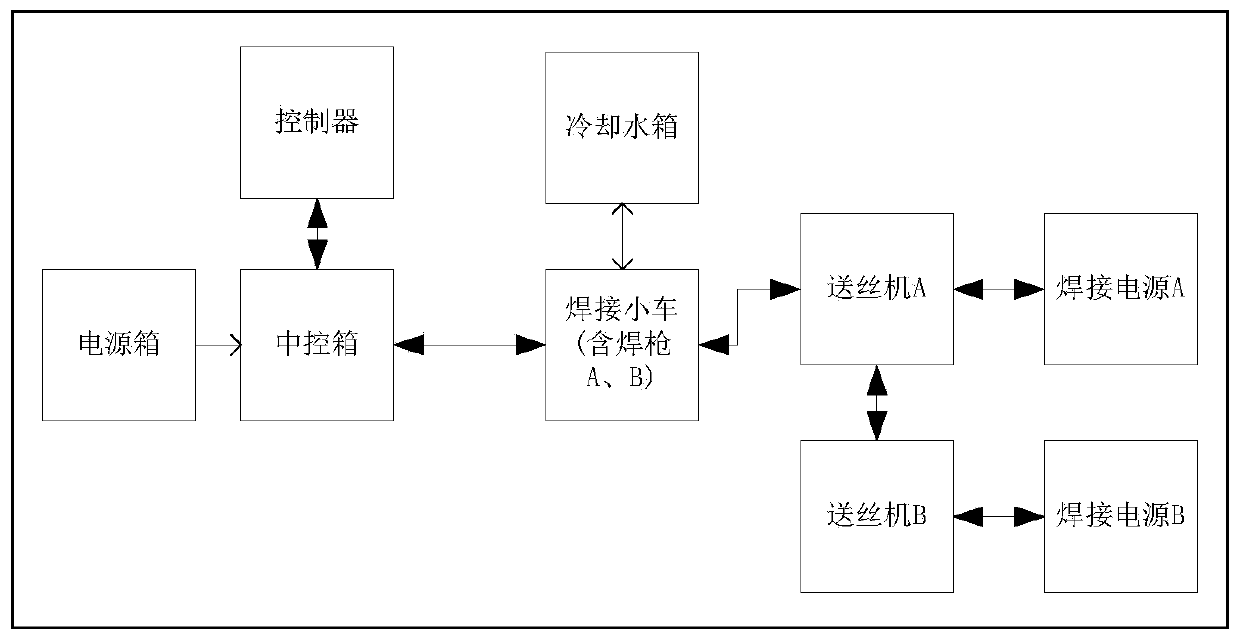

[0043] This embodiment proposes a dual torch intelligent welding system, which mainly includes a welding trolley 1, a central control power box 2, two wire feeders 3 (wire feeder A and wire feeder B), control devices 4, 2 A welding gun 5 (welding gun A and welding gun B), two welding power sources 6 (welding power source A and welding power source B), cooling water tank 7, grounding device 8, shielding gas supply system and supporting control cables, etc., such as figure 1 shown. Wherein, the central control power supply box includes a central control box 202 and a power supply box 201 , and the power supply box 201 supplies power to the central control box 202 .

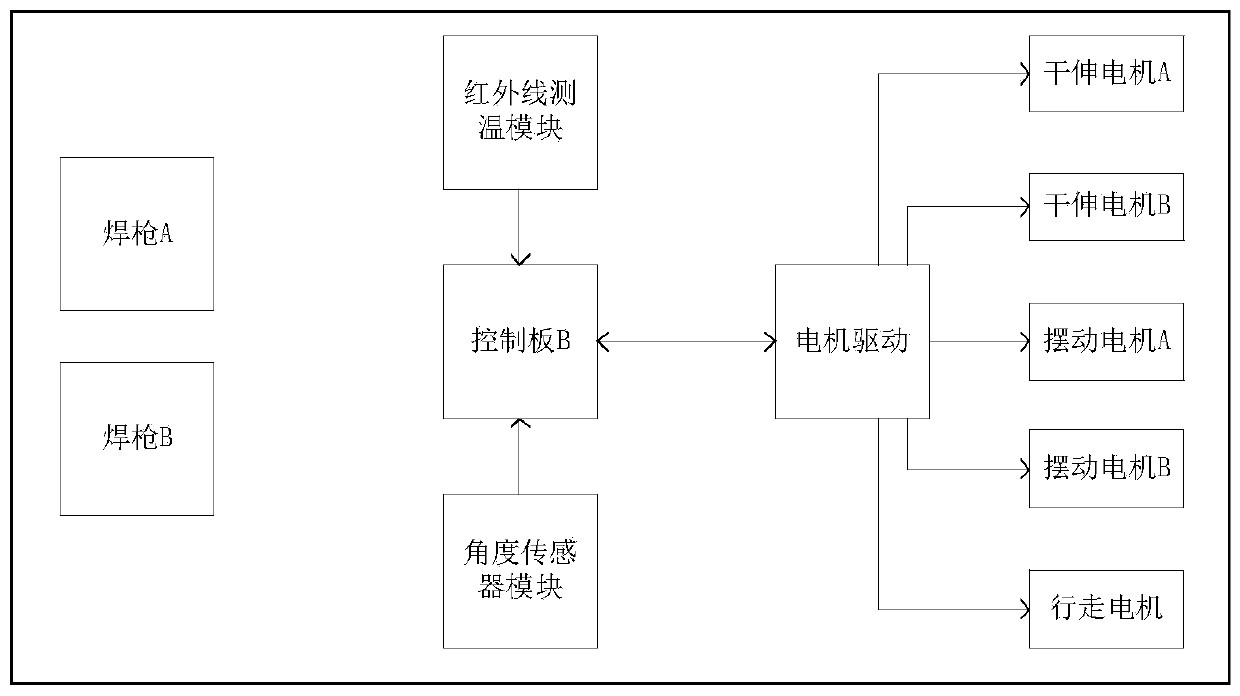

[0044] In this embodiment, the central control box 202 is the control center of the entire welding system, and the controller 4 is connected to the central control box 202 as a human-computer interaction interface; welding torch A and welding torch B are installed on the welding trolley 1, and The welding trolley 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com