Laser intersecting line cutting machine free of cam replacement

A laser cutting and intersecting line technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high price and lack of simple intersecting line cutting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

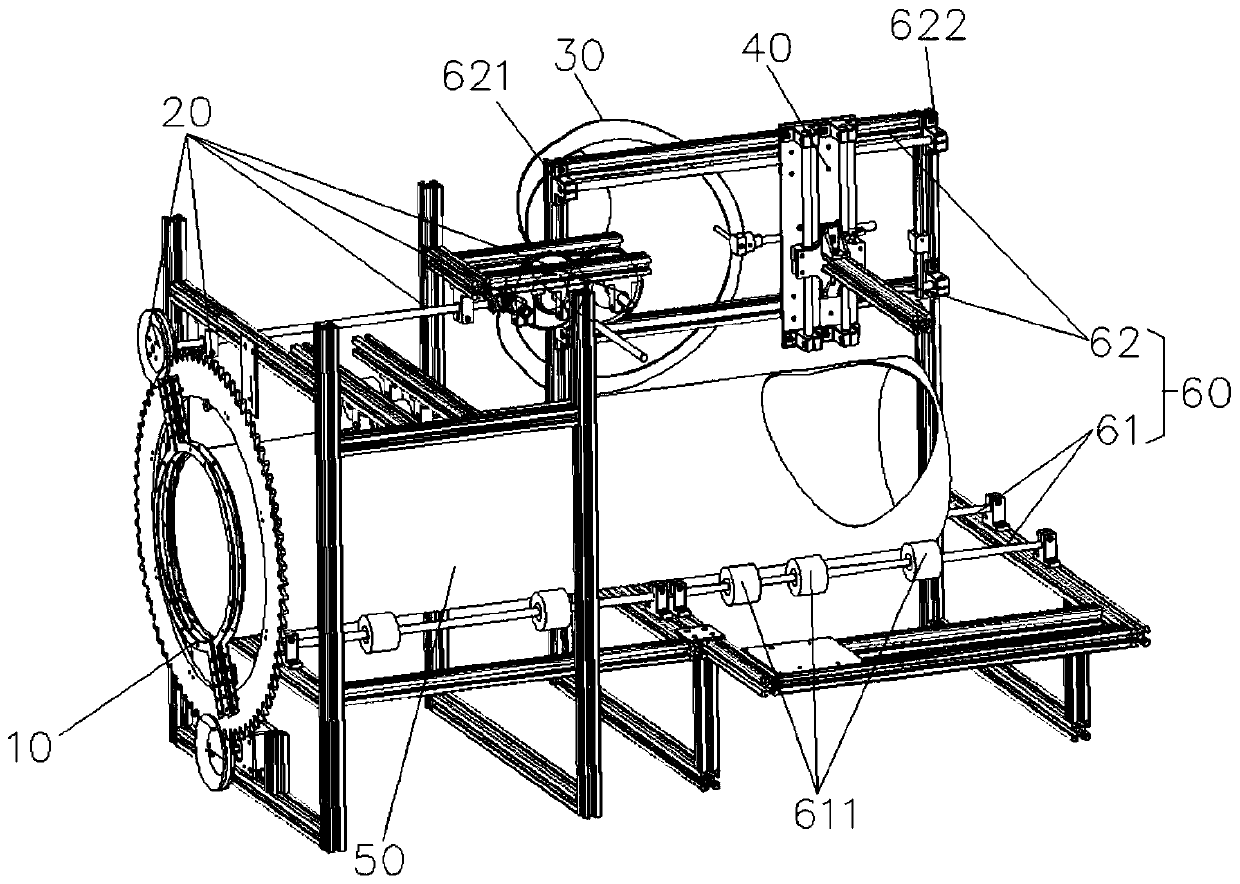

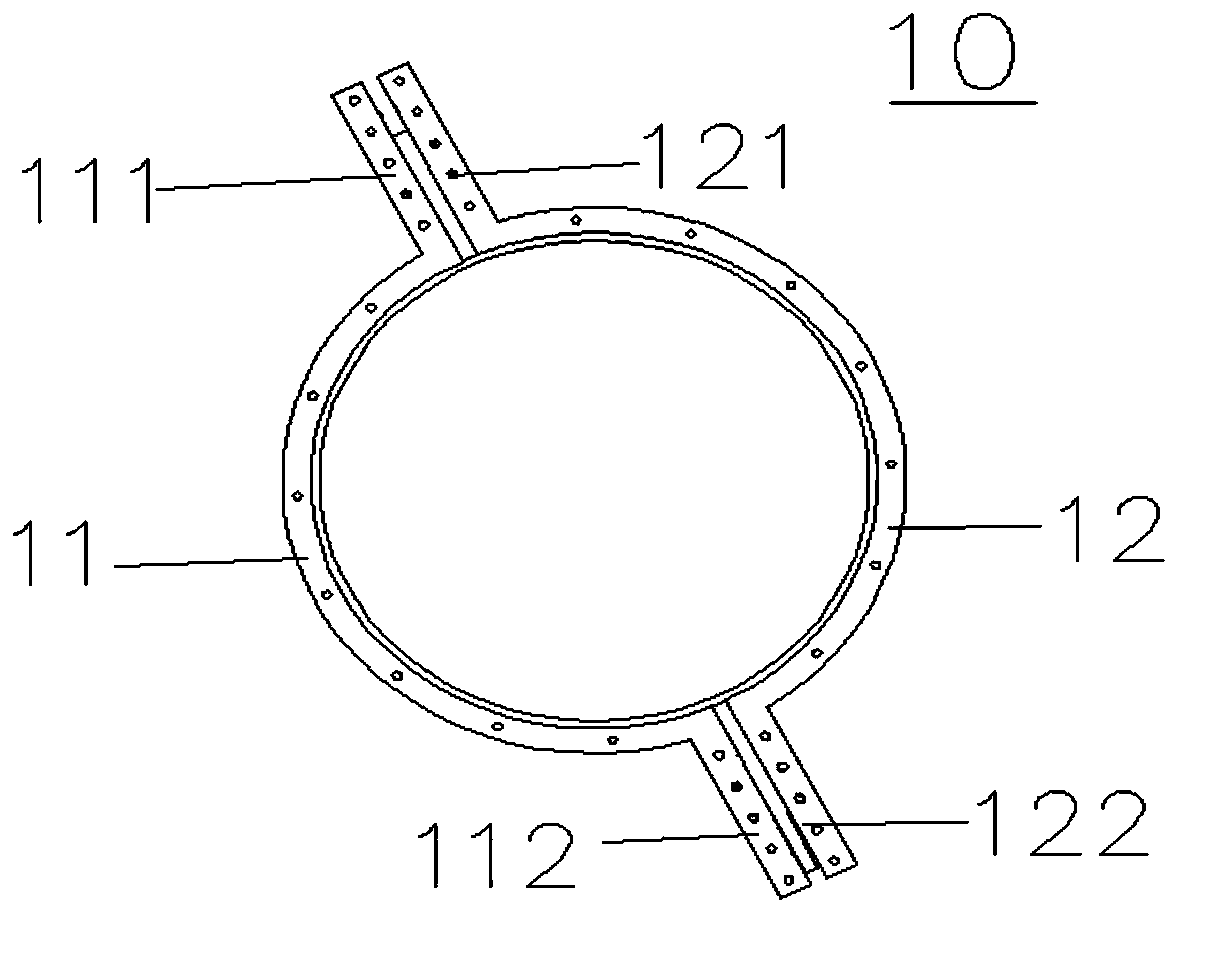

[0061] The embodiment of the present invention provides a laser intersecting wire cutting machine without changing the cam, such as figure 1 , Figure 13 to Figure 16 As shown, it includes: a pipe clamping fixture 10, a gear transmission assembly 20, a first cam 30, a second cam 70 and a laser cutting assembly 40;

[0062] The pipe clamping fixture 10 is used to clamp the pipe 50 to be cut;

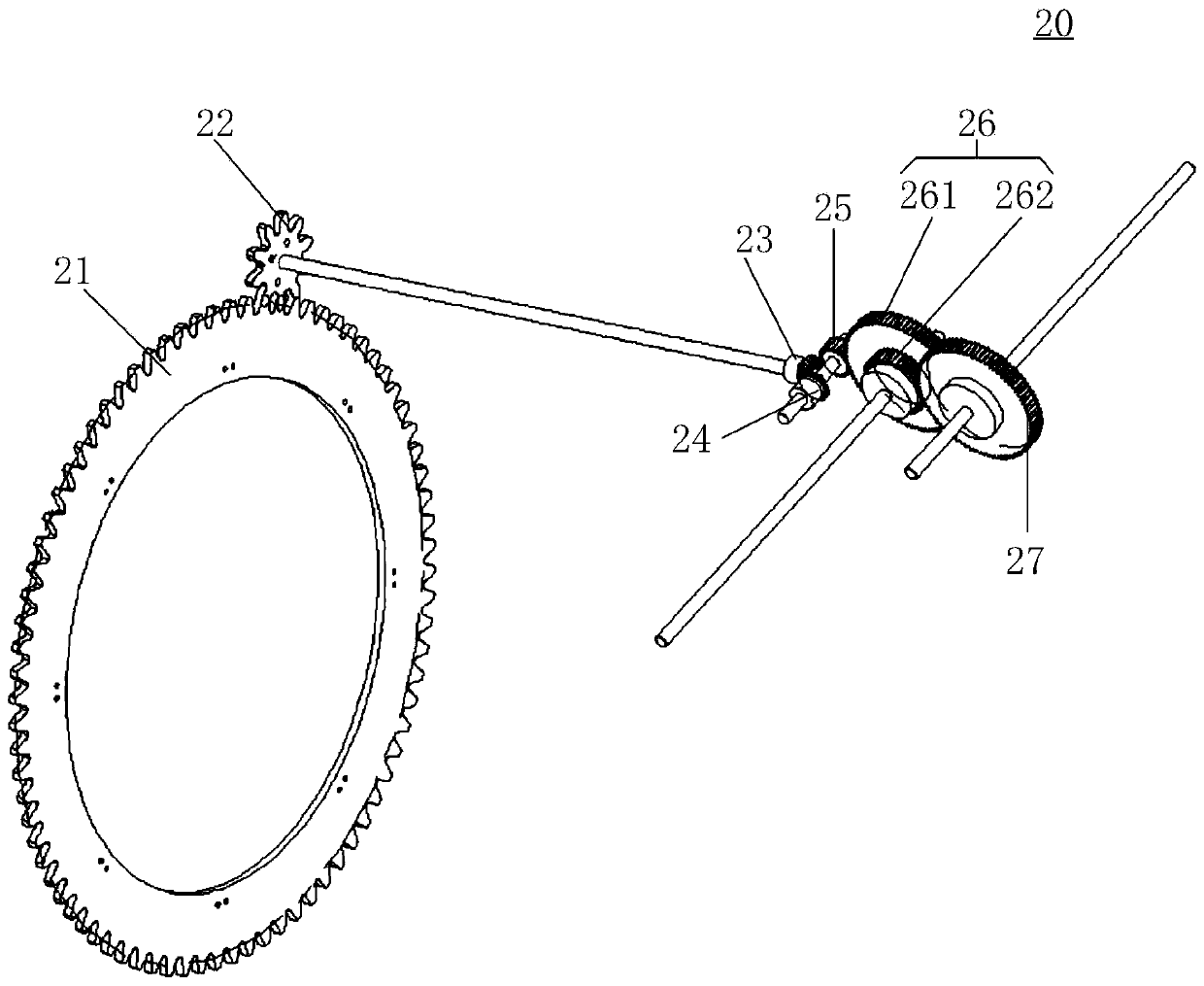

[0063] The gear transmission assembly 20 is connected to the pipe clamping fixture 10, and the gear transmission assembly 20 rotates with the rotation of the pipe 50 to be cut;

[0064] The first cam 30 and the second cam 70 are arranged side by side, the gear transmission assembly 20 connects the first cam 30 and the second cam 70 , and the gear transmission assembly 20 drives the first cam 30 and the second cam 70 rotates, the first cam 30 is used to generate the trajectory of radially intersecting lines, and the second cam 70 is used to generate the trajectory of axially intersecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com