Rolling device for dust-proof cap of automobile lock cylinder

A rolling device, dust cap technology, applied in metal processing equipment, metal processing, manufacturing tools and other directions, can solve the problems of dust cap deformation, poor sealing, accelerated wear of the sealing ring, etc., to achieve product quality improvement, The effect of improving durability and life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

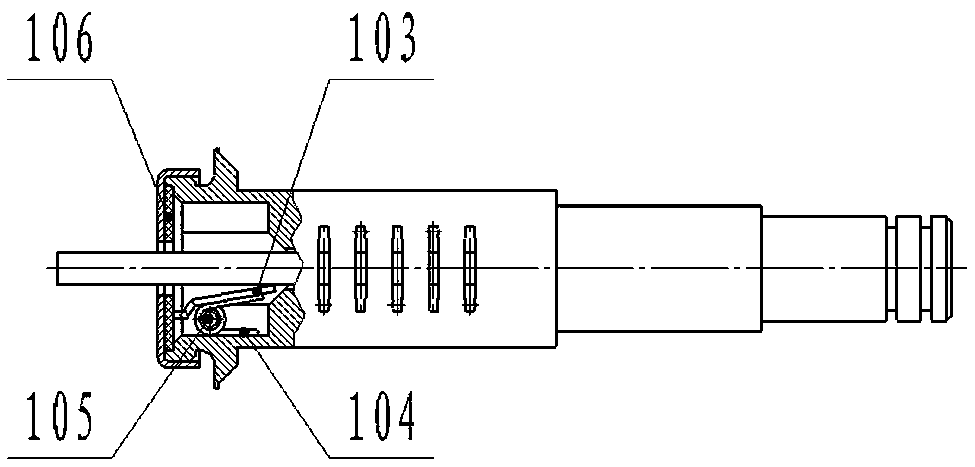

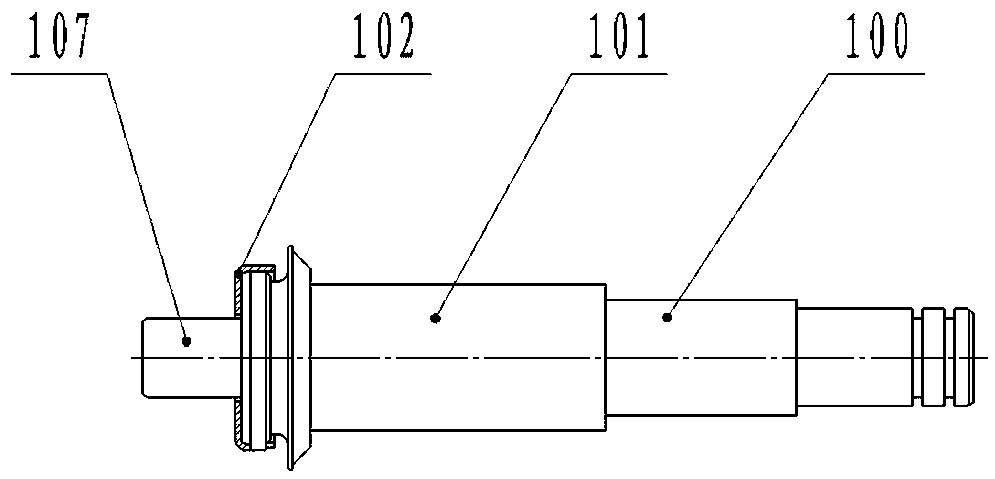

[0030] The car lock cylinder to be rolled in this application, the car lock cylinder assembly 100 before the blade pins are assembled, such as Figure 1a , 1b As shown, it includes a lock cylinder 101, a dust cap 102, a turning piece 103, a double-leg spring 104, a pin shaft 105 and a gasket 106, wherein the turning piece 103, a double-leg spring 104, a pin shaft 105 and a sealing gasket 106 are located in the lock Inside the core 101, inserting the key blank 107 can prevent the springs 104 from bouncing up. The key blank 107 is an auxiliary tool for the assembly of the lock core dust cap. It is assembled using the rolling device of the present application. The specific parts used in this application are only As a specific embodiment of the present application, other parts with the same function instead of the present application also belong to the protection scope of the present application.

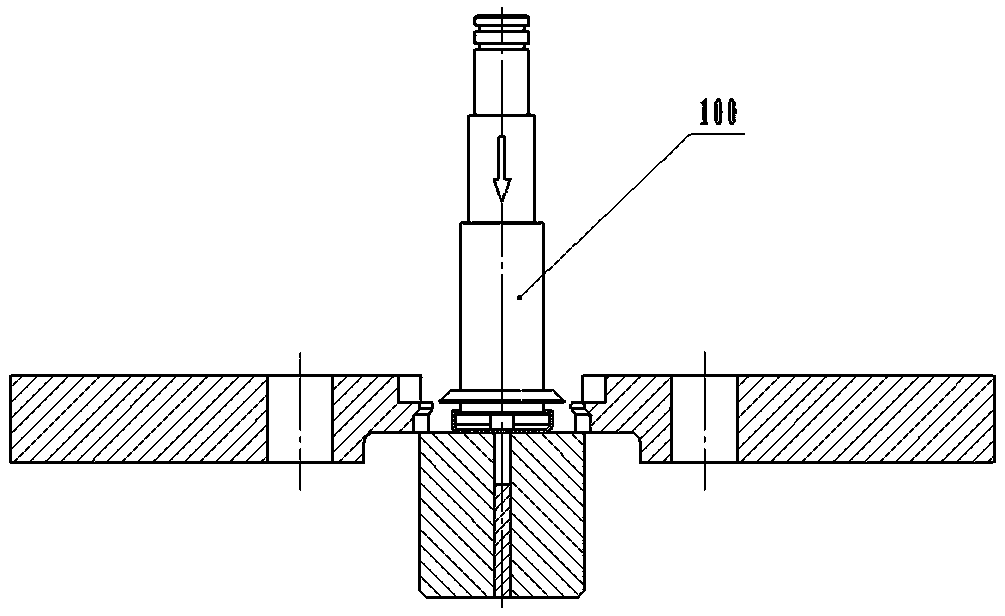

[0031] according to Figure 3-4 , the device of the present application is encaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com