Automatic bag mouth shaping and heat seal sealing integration machine, and shaping and heat sealing method

A heat sealing, all-in-one technology, used in transportation and packaging, packaging sealing/fastening, external support, etc., can solve the problems of inconsistency in packaging production lines, low production line work efficiency, and high capital costs, to meet mass production. , high work efficiency, high equipment integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

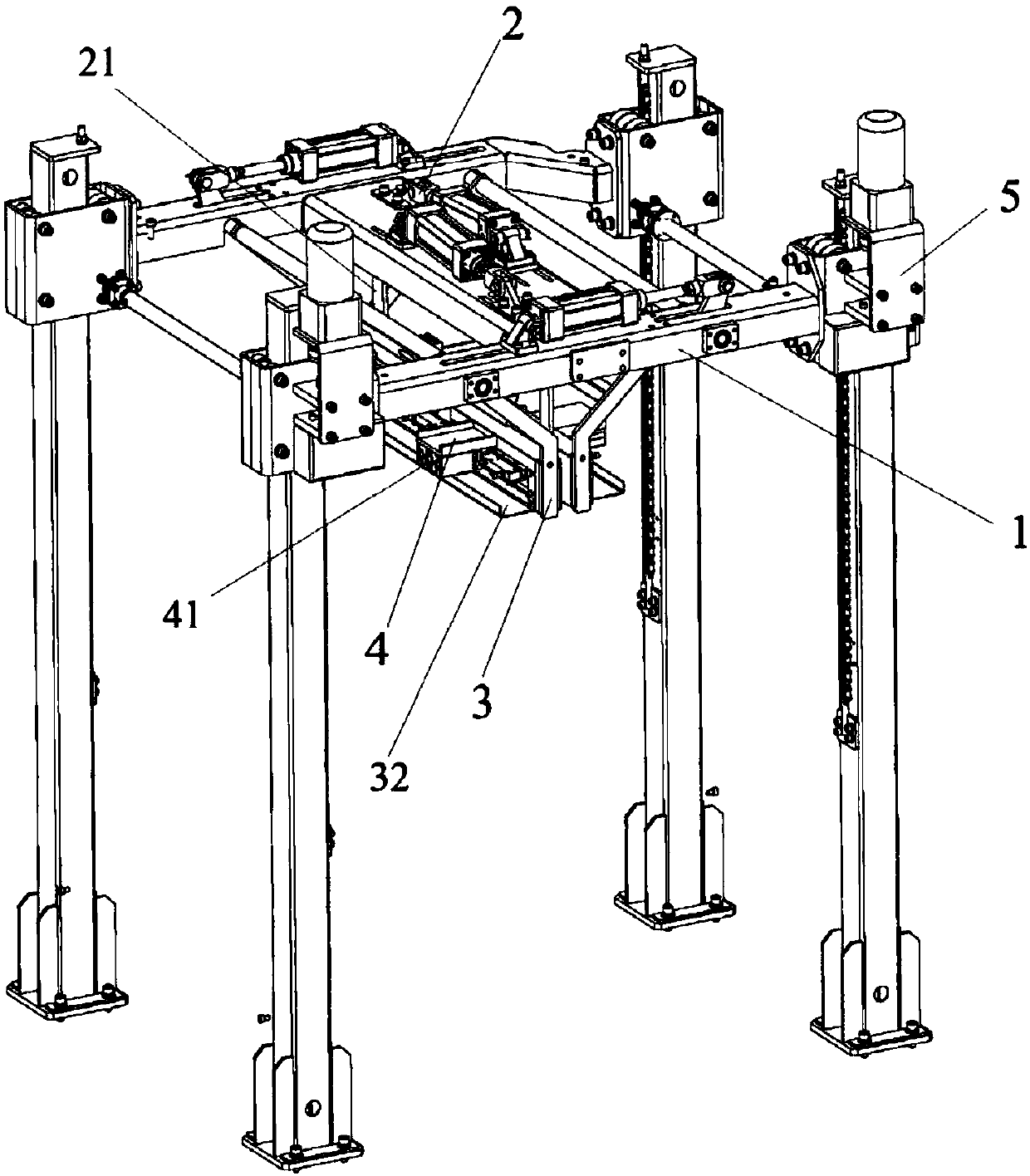

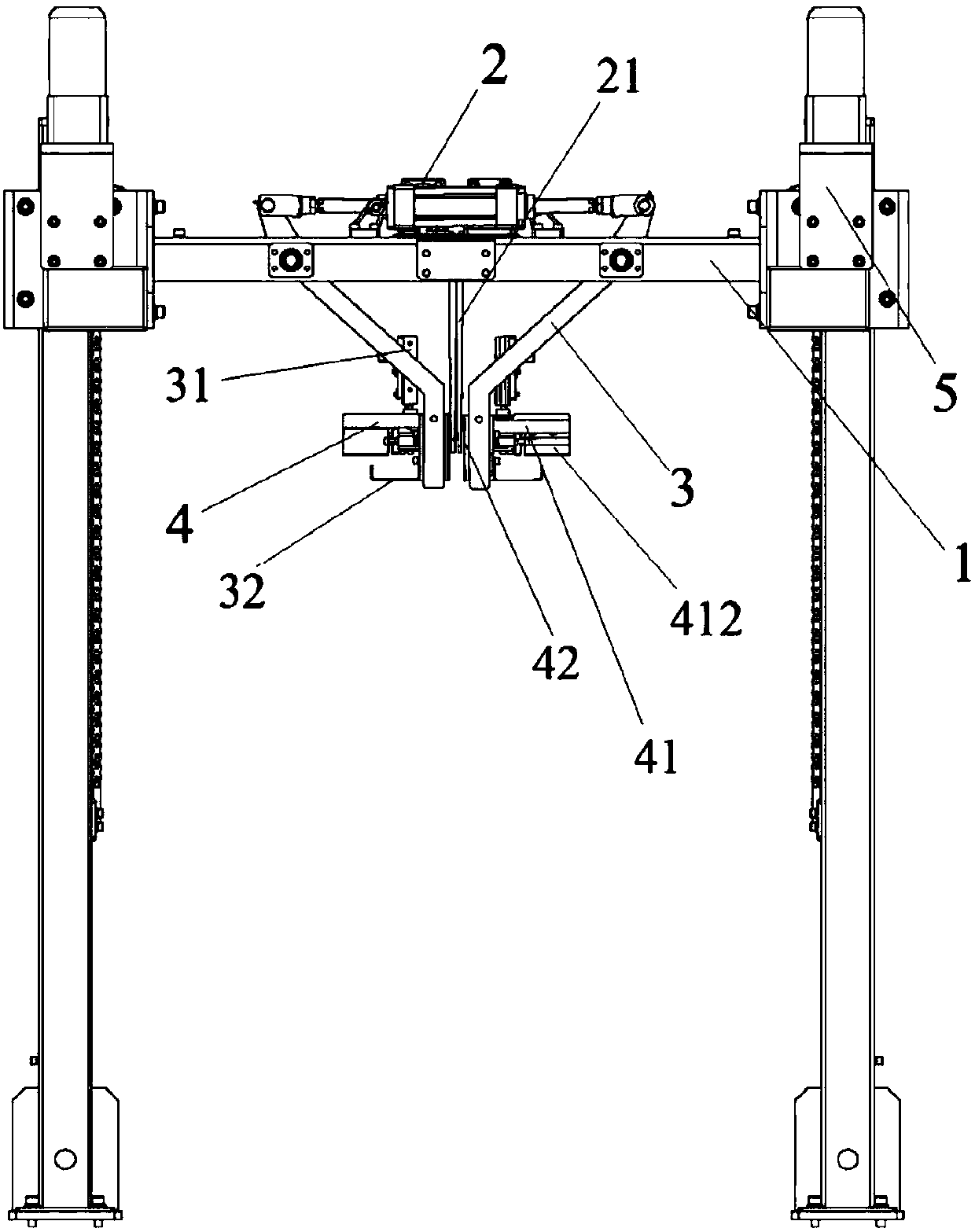

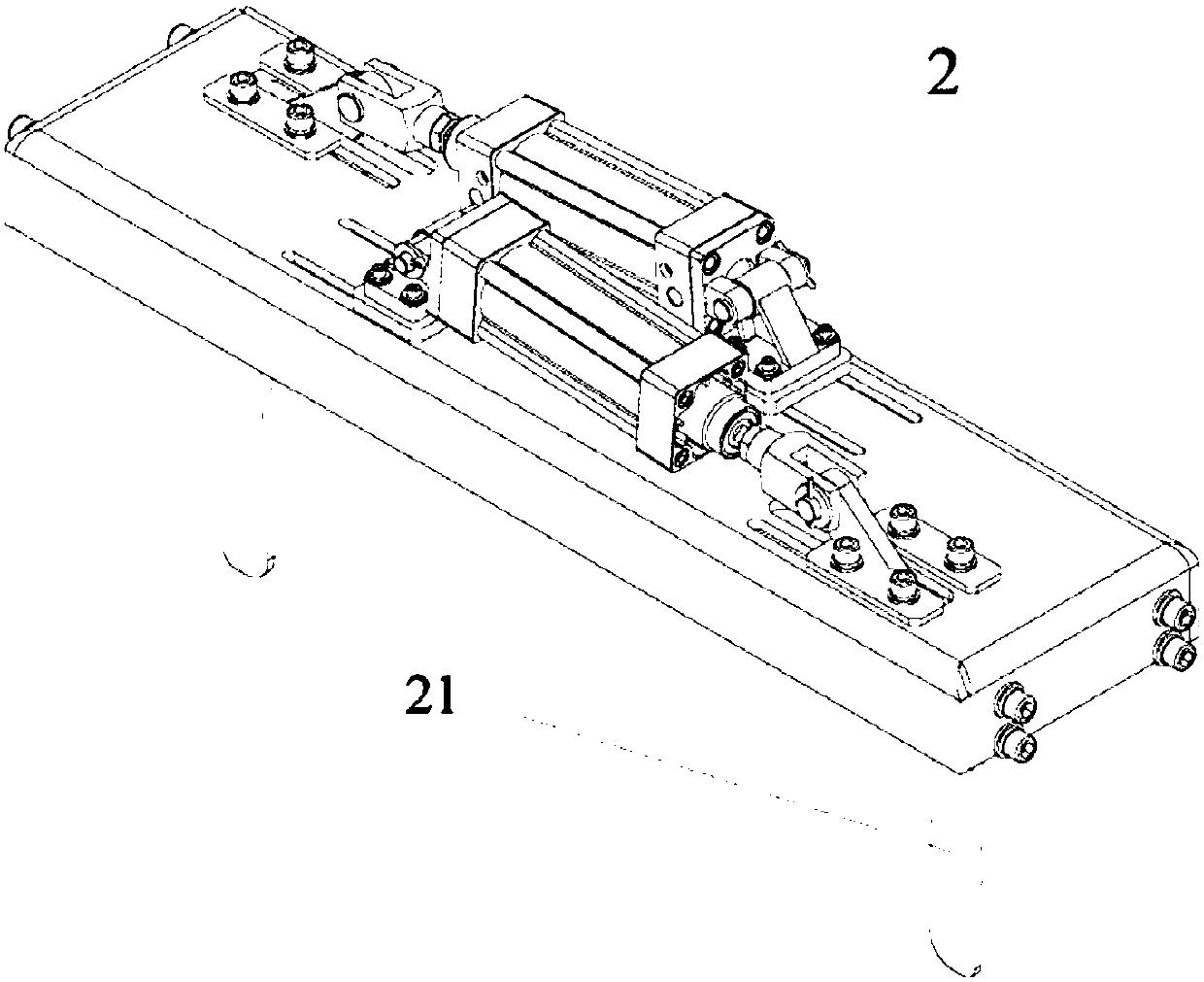

[0053] Such as Figure 1 to Figure 4 As shown, an automatic pocket shaping and heat sealing machine includes a frame 1, a bag pulling device 2 and a bag clamping device 3, the bag pulling device 2 is installed in the middle of the upper part of the frame 1, and the clamping The bag device 3 is installed on the top of the frame 1, on both sides of the bag pulling device 2, and also includes a heat sealing device 4; Side-mounted and bilaterally symmetrical.

[0054] The heat sealing device 4 includes two sets of heat sealing pushing devices 41 symmetrically arranged, a heat sealing block 42 and a heating pipe 43, the heating pipe 43 is installed in the heat sealing block 42, and the heat sealing block 42 is fixedly connected to the clip bag At the lower end of the device 3, the heat-sealing pushing device 41 drives the heat-sealing block 42 to move in opposite directions and maintain pressure.

[0055] The lower end of the bag clamping device 3 is symmetrically provided with a...

Embodiment 2

[0072] Such as Figure 5 , Image 6 , as shown, Figure 5 , Image 6 It is a structural schematic diagram of the second preferred embodiment of an automatic pocket shaping and heat sealing machine of the present invention. This embodiment is basically the same as the first embodiment, the only difference is: in order to meet the production line requirements of different products and different packaging angles, the heat sealing device 4 is installed under the bag clamping device 3 through the heat sealing platform 6: the above A bag-pressing plate 32 is arranged symmetrically at the lower end of the bag-clamping device 3 , and a heat-sealing platform 6 is arranged below the bag-pressing plate 32 , and the heat-sealing device 4 is symmetrically arranged on the heat-sealing platform 6 .

[0073] Please refer to Figure 7 , Figure 8 , in order to facilitate the folding of the heat-sealing device 4, the heat-sealing platform 6 is connected to the frame through the rotating sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap