Tracked ore transfer car positioning system and positioning method thereof

A technology of positioning system and mining vehicle, which is applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve problems such as hindering production efficiency, impact of automated production, and positioning errors of RFID tags to achieve accurate solutions The effect of locating problems, promoting automation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

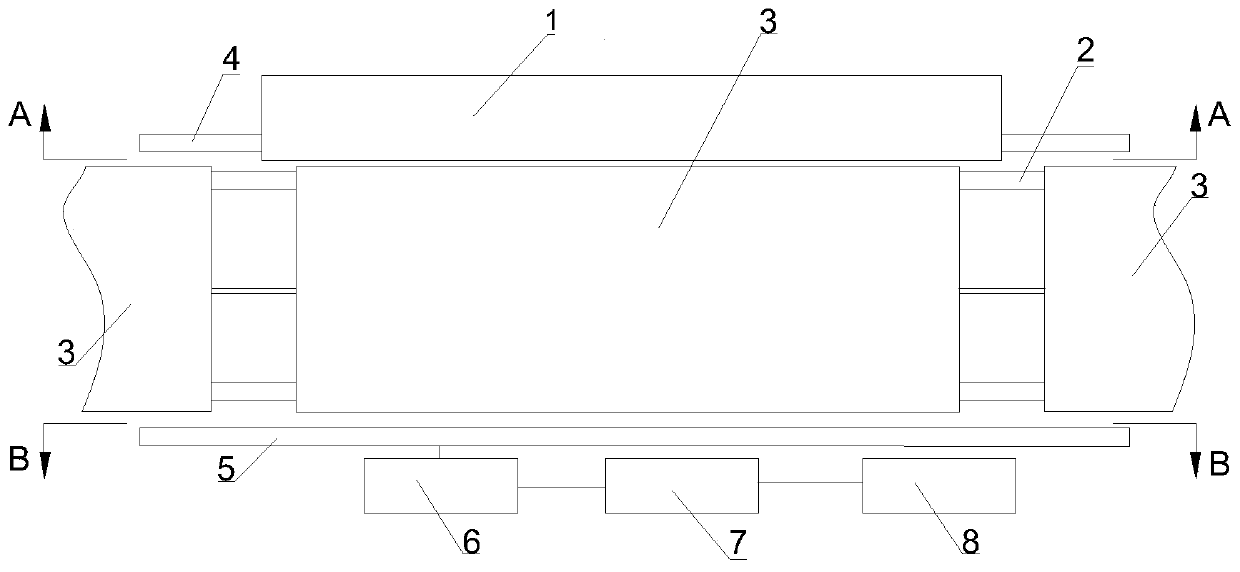

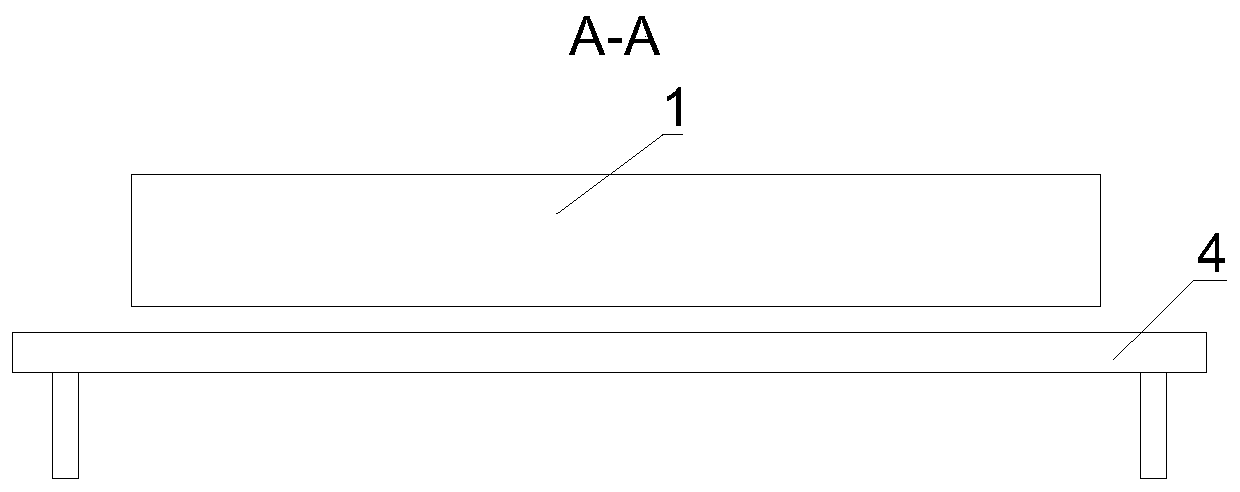

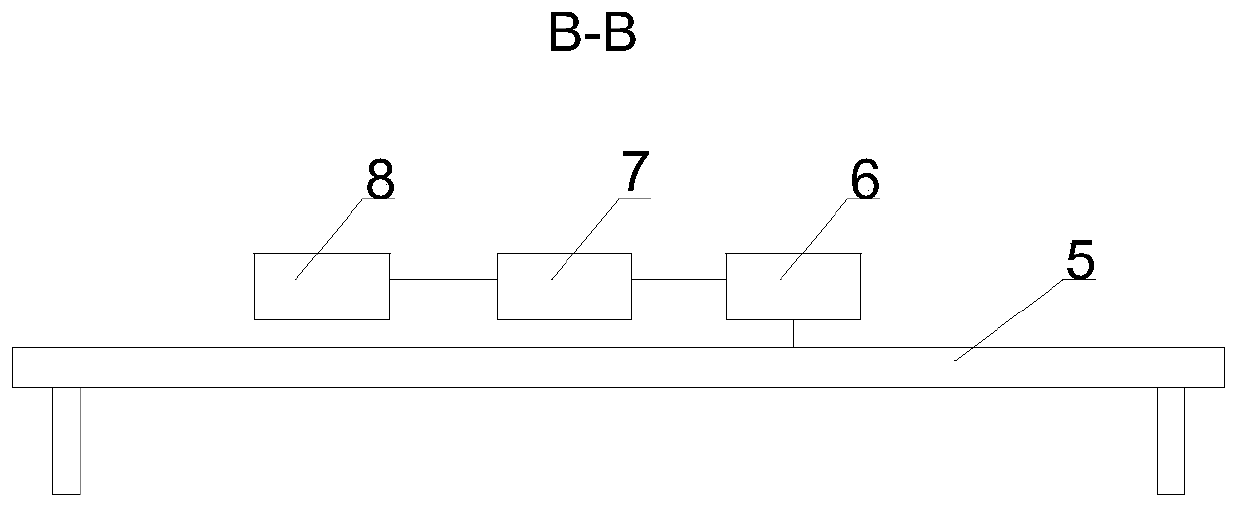

Image

Examples

Embodiment

[0057] A total of 5 rail mine vehicles are intertwined, and the positioning steps are as follows:

[0058] 1). Make the five interlocking ore trucks drive from left to right, place the area in front of the first ore truck, the space between every pair of adjacent ore trucks, and the rear of the last ore truck. The area of the grid is set as the penetration point of the grating, and the penetration points are numbered 1, 2, 3, 4, 5, 6 from small to large from right to left;

[0059] 2). When the grating receiver receives the gratings of penetration points 1 and 2 at the same time;

[0060] 3). The grating receiver transmits the signal to the data processor through the communication interface, and the data processor transmits the control signal generated by it to the controller, and the controller controls the mine truck to stop;

[0061] 4). Whether the grating receiver keeps receiving the gratings of penetration points 1 and 2;

[0062]5). If the grating receiver keeps rec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap