Magnetic field induced fiber reinforced polyimide composite material and preparation method thereof

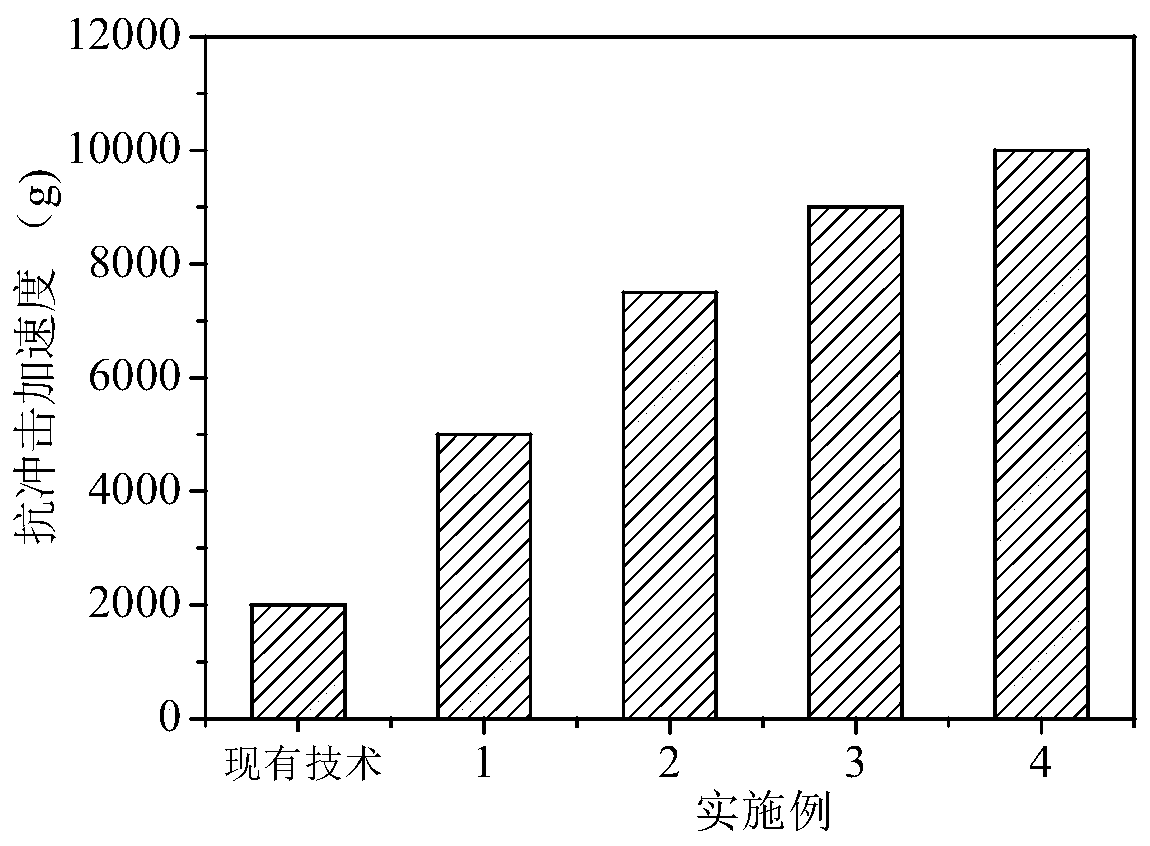

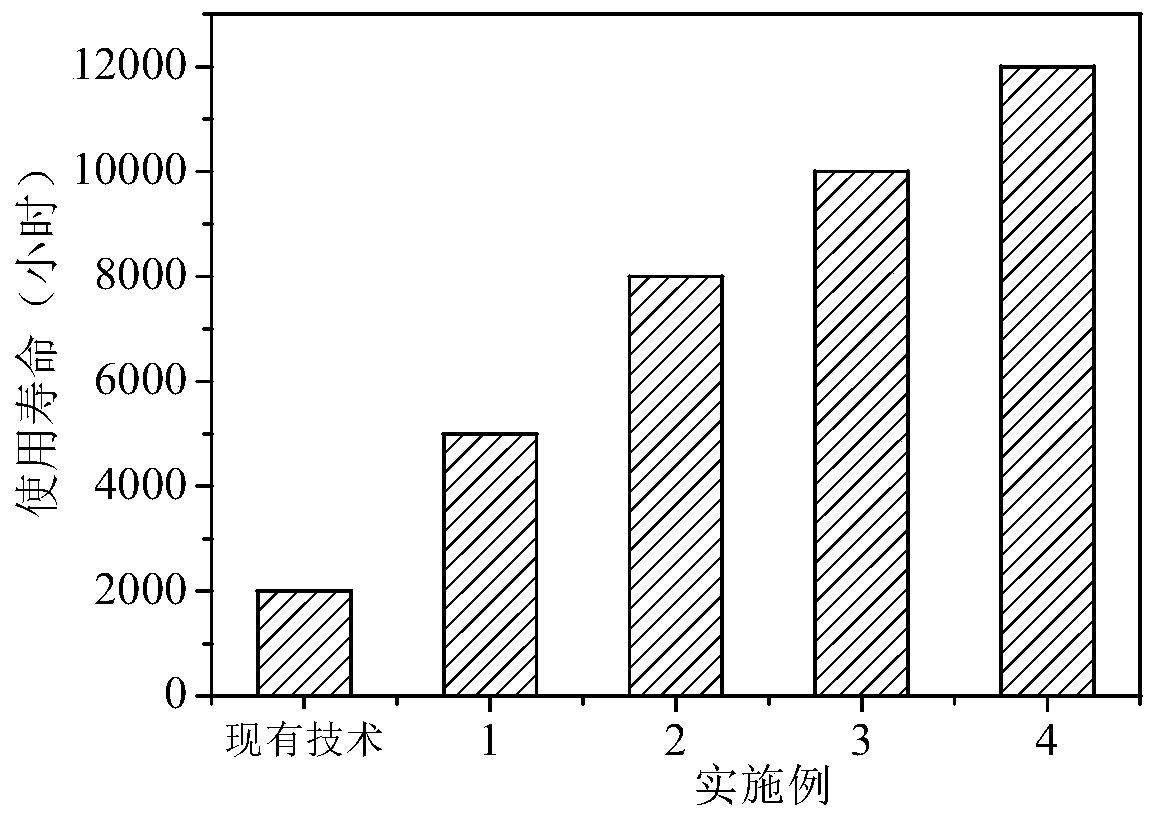

A polyimide and fiber-reinforced technology, which is applied in the field of magnetic field-induced fiber-reinforced polyimide composite materials and its preparation, can solve the problem that the impact resistance performance cannot meet the use requirements, and achieve good impact resistance and excellent mechanical properties , Improve the effect of creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A magnetic field-induced fiber-reinforced polyimide composite material is prepared by the following steps:

[0026] 1) Disperse 0.02 g of magnetic Fe3O4 nanoparticles and 0.2 g of chopped carbon fibers in 50 ml of anhydrous ethanol solution for ultrasonic stirring, and then dry to obtain magnetic Fe3O4 nanoparticles loaded on the surface of carbon fibers for use.

[0027] 2) Put the two monomers of ODA and PMDA in a vacuum drying oven at 80±10°C for 2 hours and store for later use; add 2.18g of dried PMDA to 20 ml of DMA solution, add 2g of ODA after dissolution, and Stir in an ice-water bath for 8 ± 0.5 hours to synthesize polyamic acid, add 5% w.t. carbon fiber coated with iron tetraoxide to the polyamic acid, continue stirring for 2 ± 0.5 hours, and then spread it on a dry and clean glass plate. The sample was placed in a constant magnetic field (field strength of 100 gauss) and heated in a vacuum drying oven until the solvent was volatilized. Finally, the temperatur...

Embodiment 2

[0030] A magnetic field-induced fiber-reinforced polyimide composite material is prepared by the following steps:

[0031] 1) Disperse 0.04g of magnetic Fe3O4 nanoparticles and 0.4g of chopped carbon fibers in 50 ml of anhydrous ethanol solution with ultrasonic stirring, and then dry to prepare magnetic Fe3O4 nanoparticles loaded on the surface of carbon fibers for use.

[0032] 2) Put the two monomers ODA and PMDA in a vacuum oven at 80°C to dry for 2 hours, and store for later use; add 2.18g of dried PMDA to 23 ml of DMA solution, add 2g of ODA after dissolution, and place in an ice-water bath Stir in medium for 8 hours to synthesize polyamic acid, add 10% w.t. carbon fiber coated with iron tetroxide to polyamic acid, continue to stir for 2 hours, spread it on a dry and clean glass plate, put the sample in a constant magnetic field (The field strength is 120 gauss) Heating in a vacuum drying oven until the solvent is volatilized, and finally raising the temperature to 380°C ...

Embodiment 3

[0035] A magnetic field-induced fiber-reinforced polyimide composite material is prepared by the following steps:

[0036] 1) Disperse 0.08g of magnetic Fe3O4 nanoparticles and 0.8g of chopped carbon fibers in 50 ml of anhydrous ethanol solution with ultrasonic stirring, and then dry to obtain magnetic Fe3O4 nanoparticles loaded on the surface of carbon fibers for use.

[0037] 2) Put the two monomers ODA and PMDA in a vacuum oven at 80°C to dry for 2 hours, and store them for later use; add 2.18g of dried PMDA to 24 ml of DMA solution, add 2g of ODA after dissolution, and place in an ice-water bath Stir in medium for 8 hours to synthesize polyamic acid, add 20% w.t. carbon fiber coated with iron tetraoxide to polyamic acid, continue stirring for 2 hours, spread it on a dry and clean glass plate, put the sample in a constant magnetic field (The field strength is 180 gauss) Heating in a vacuum drying oven until the solvent volatilizes, and finally raising the temperature to 380...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap