Fast wine brewing machine

A brewing machine and fast technology, applied in the field of brewing machines, can solve the problems of long brewing cycle, unable to meet demand, difficult to ensure wine quality, etc., and achieve the effects of good leakage effect, rapid processing and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

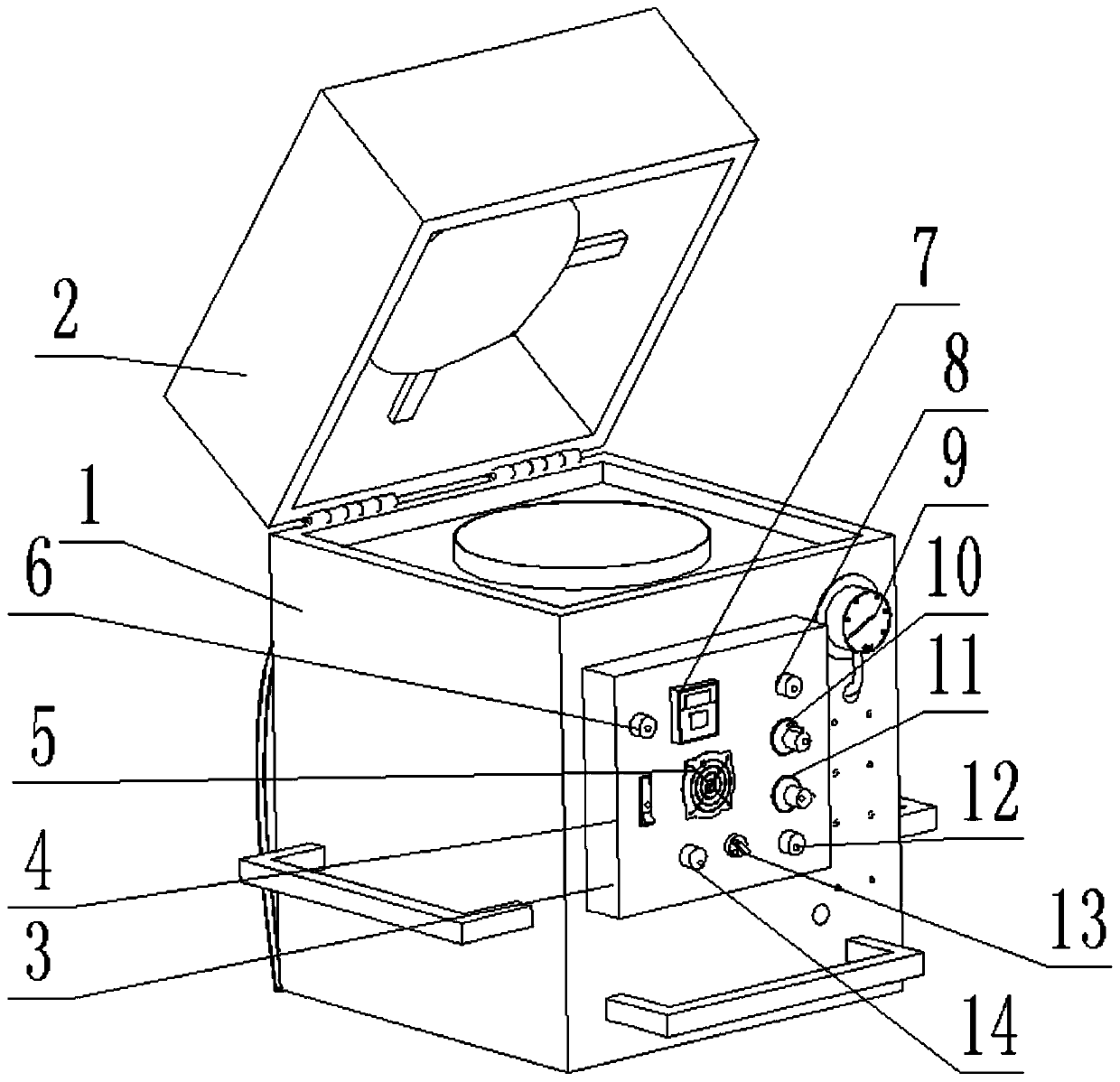

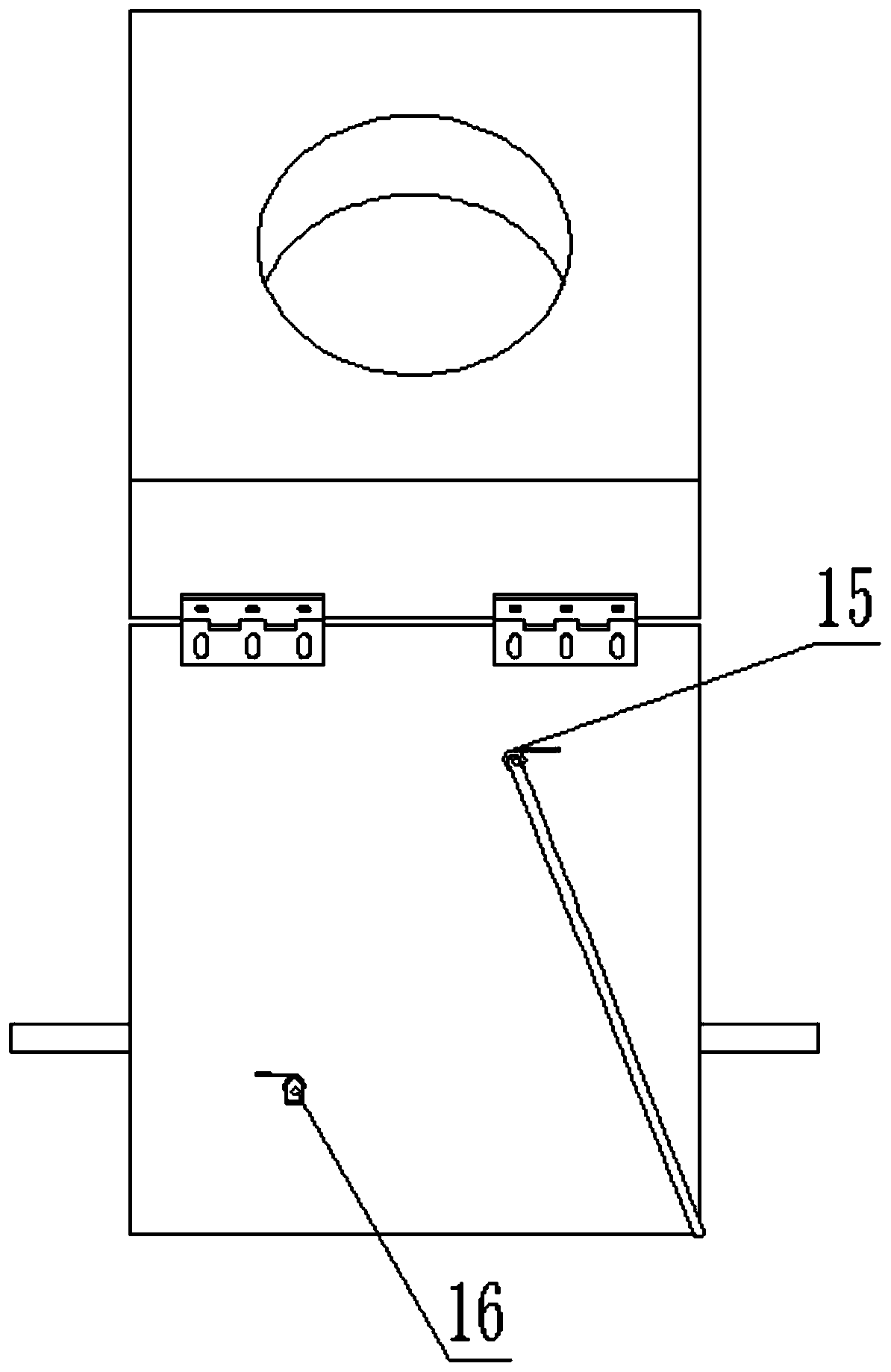

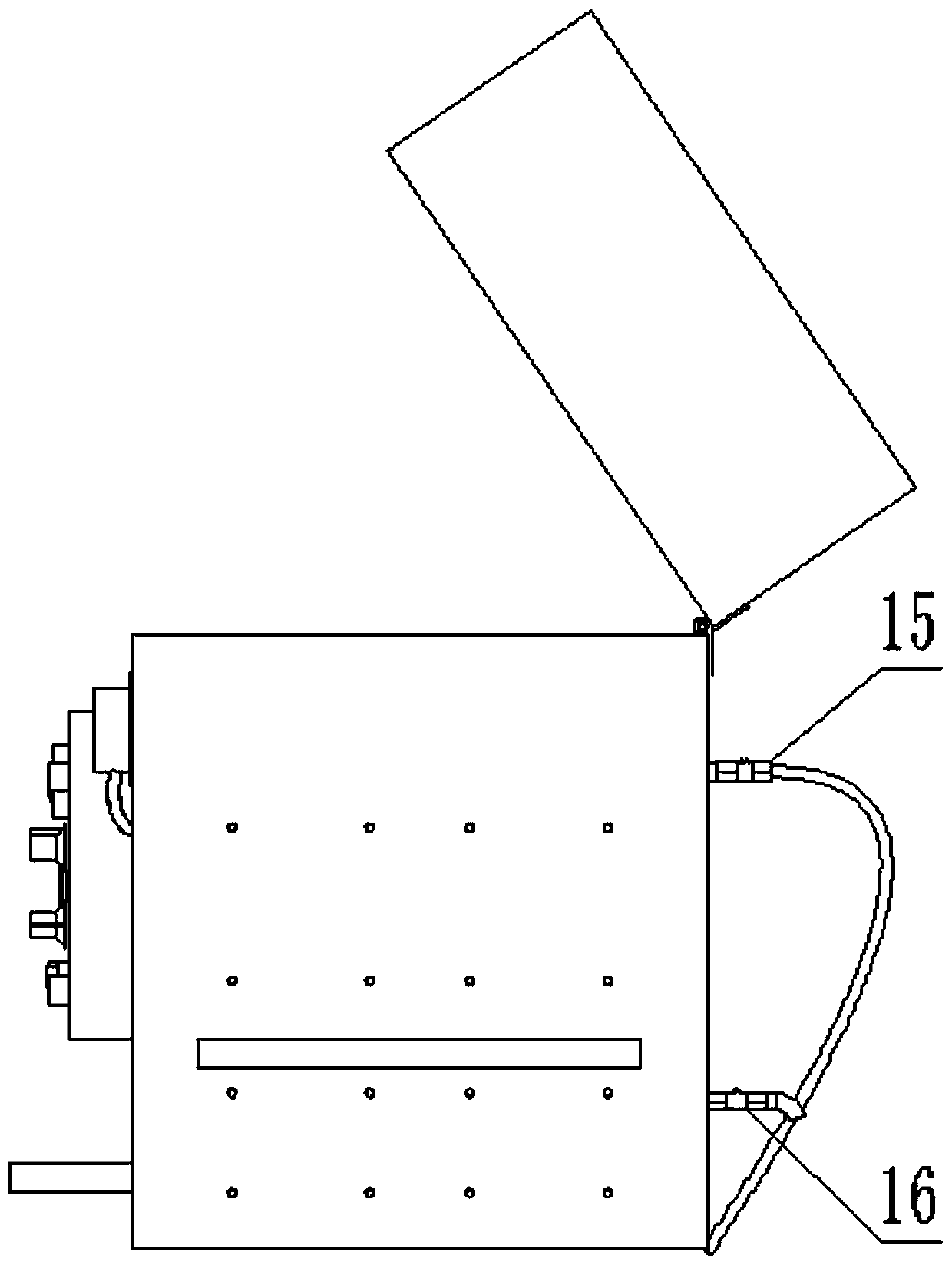

[0019] see Figure 1-4 , a fast brewing machine, comprising a case 1, the top of the case 1 is provided with a case cover 2, the case cover 2 is connected to the case 1 through a hinge shaft, the inside of the case 1 is a brewing chamber, the depth of the brewing chamber is 70cm, in front of the case 1 The side is provided with a control panel 3, and the control panel 3 has a cover opening switch 4, a first heating tube switch 10, a second heating tube switch 11 and a pot bottom switch 13, and two heating tubes are arranged in the brewing cavity, one of which is The power of the heat pipe is 6kW, the power of the other heat pipe is 3kW, and the two heat pipes are respectively connected with the first heat pipe switch 10 and the second heat pipe switch 11, and the first heat pipe switch 10 is connected with the second switch indicator light 8 , the second heat pipe switch 11 is connected with a third switch indicator light 12, which is used to indicate the working status of the...

Embodiment 2

[0024] On the basis of Embodiment 1, the control panel 3 is also provided with an exhaust fan 5. When adjusting the temperature, if it is necessary to lower the temperature, the exhaust fan 5 can be started to accelerate heat dissipation, effectively reducing the temperature caused by the brewing machine. If the time is too long, the temperature will be too high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com