Gripper head for rapier loom

A technology of rapier looms and rapier heads, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of difficulty in ensuring the movement accuracy of the new yarn-connecting rod, frictional overheating of the sword shell and the yarn-connecting rod, and easy movement of the yarn-connecting rod. Misalignment and other issues, to achieve the effect of small friction, increase service life, and reduce wear speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

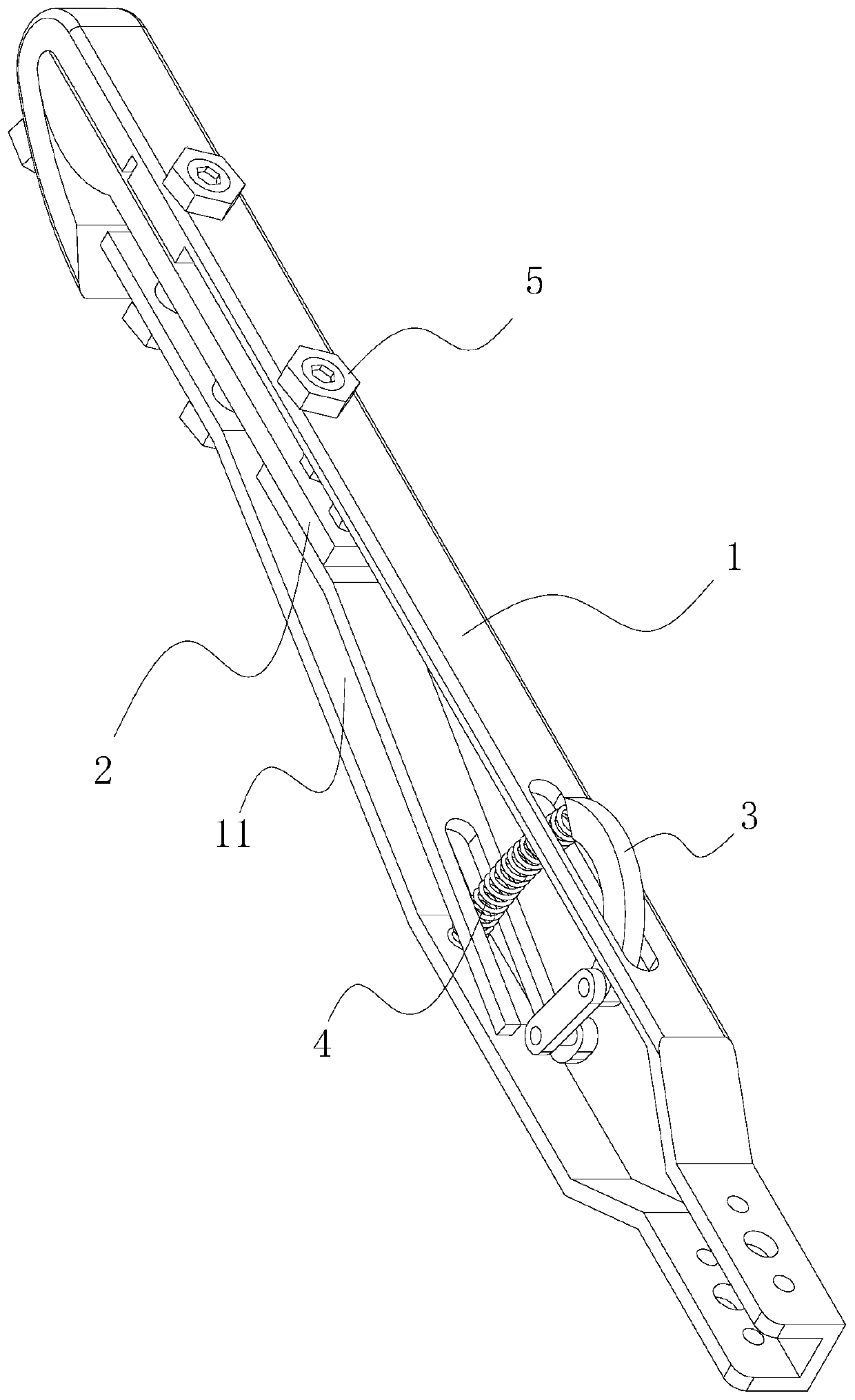

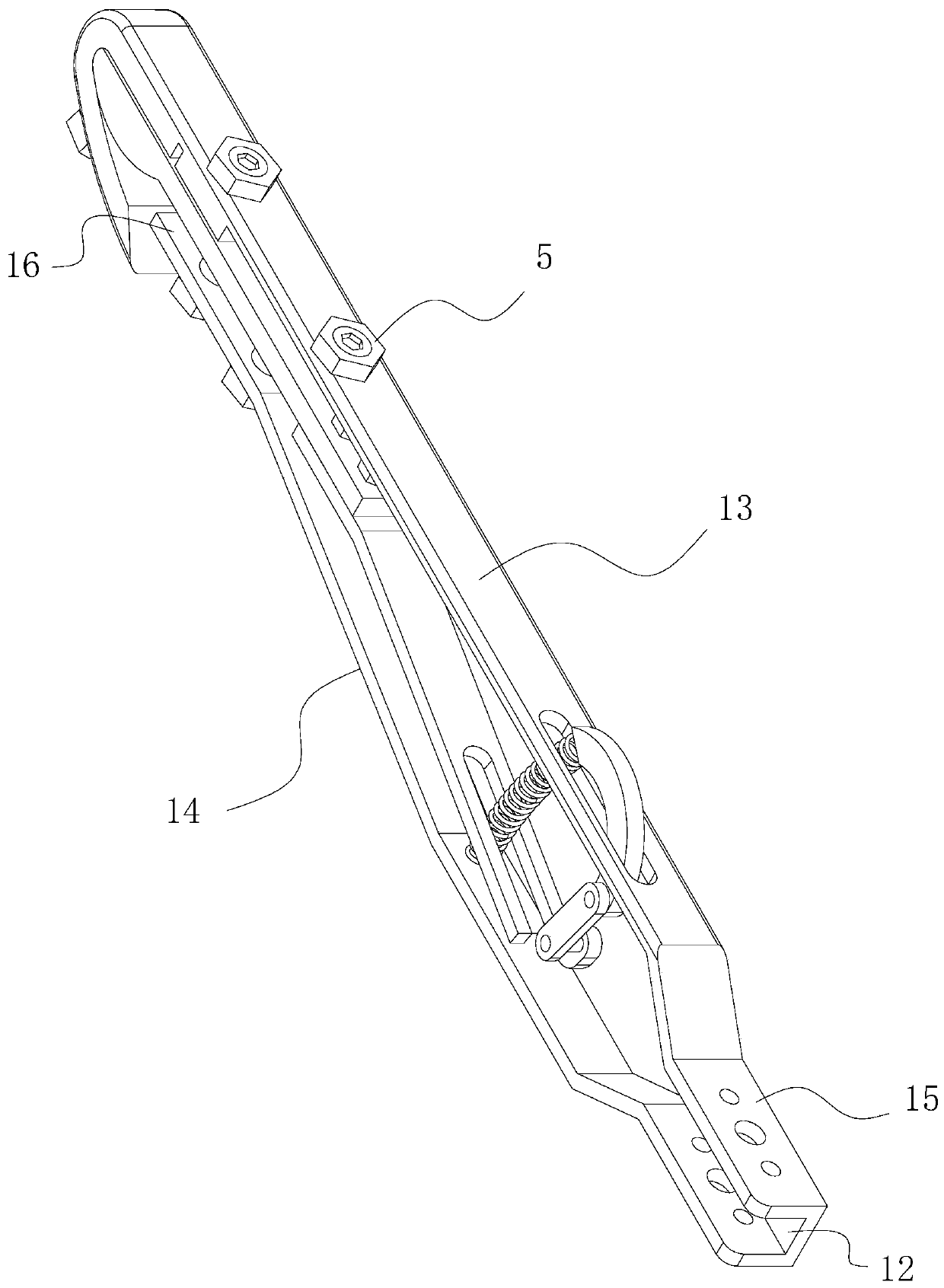

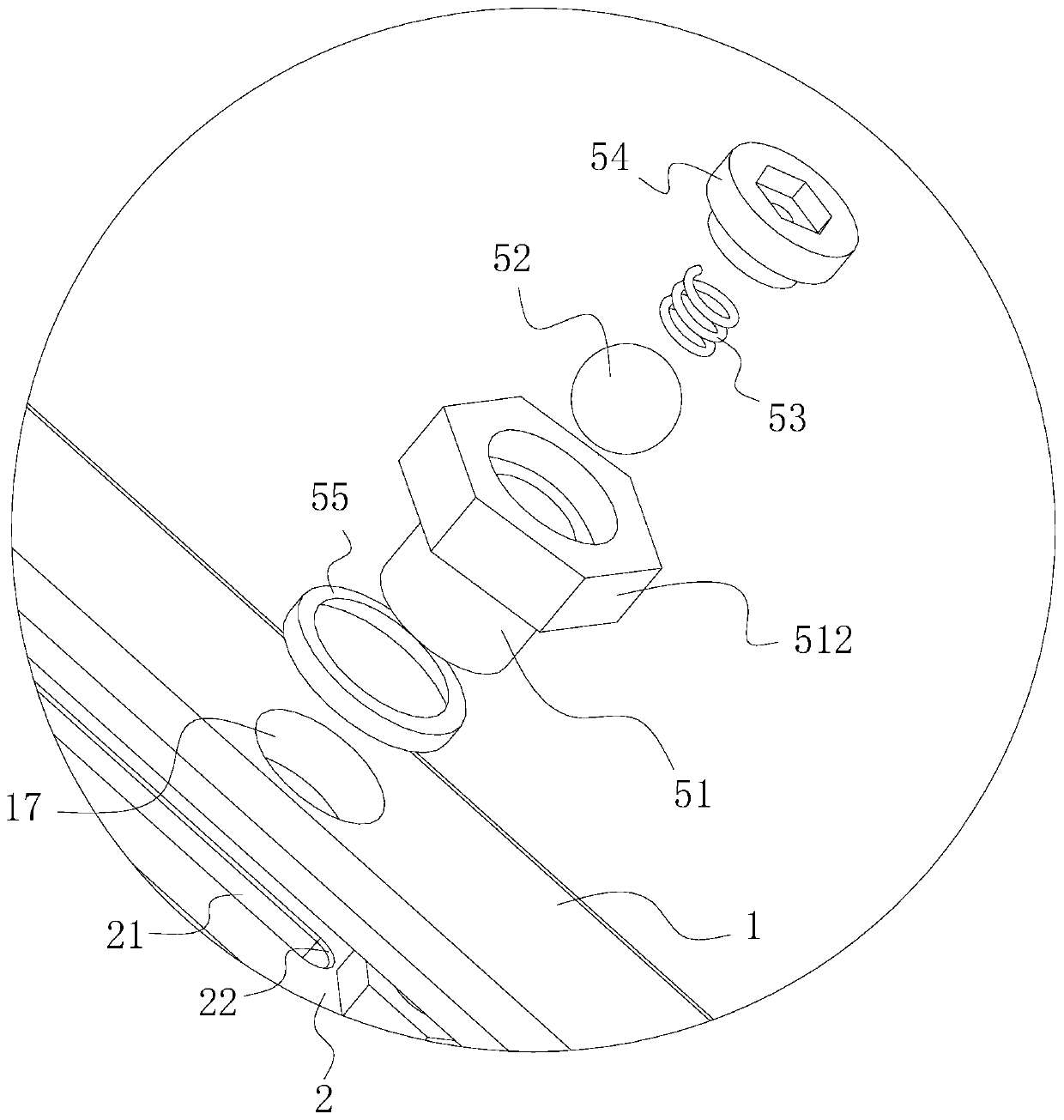

[0035] A rapier loom with a rapier head, such as figure 1 As shown, it includes a sword housing 1 provided with an accommodation area 11 inside, a yarn connecting rod 2 arranged in the accommodation area 11 for pulling weft yarns, and is rotatably mounted on the sword housing 1 with one end located in the accommodation area 11 and The extruding part 3 connected with the yarn connecting rod 2 for driving the extruding part 3 to move telescopically relative to the sword housing 1, and the two ends are respectively connected with the sword housing 1 and the extruding part 3 for driving the extruding part 3 to reset The elastic part 4 and the pressing mechanism 5 which are arranged on the casing and are respectively rollingly connected with the upper and lower sides of the yarn connecting rod 2 to avoid direct contact between the yarn connecting rod 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com