Condensation device and garment treatment equipment

A condensing device and condensed water technology, which is applied in the field of clothing processing equipment and condensing devices, can solve the problems of poor heat exchange efficiency between steam and cooling water, insufficient condensation of the condenser, and affecting drying efficiency, so as to improve condensation efficiency and efficiency Increase and accelerate the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

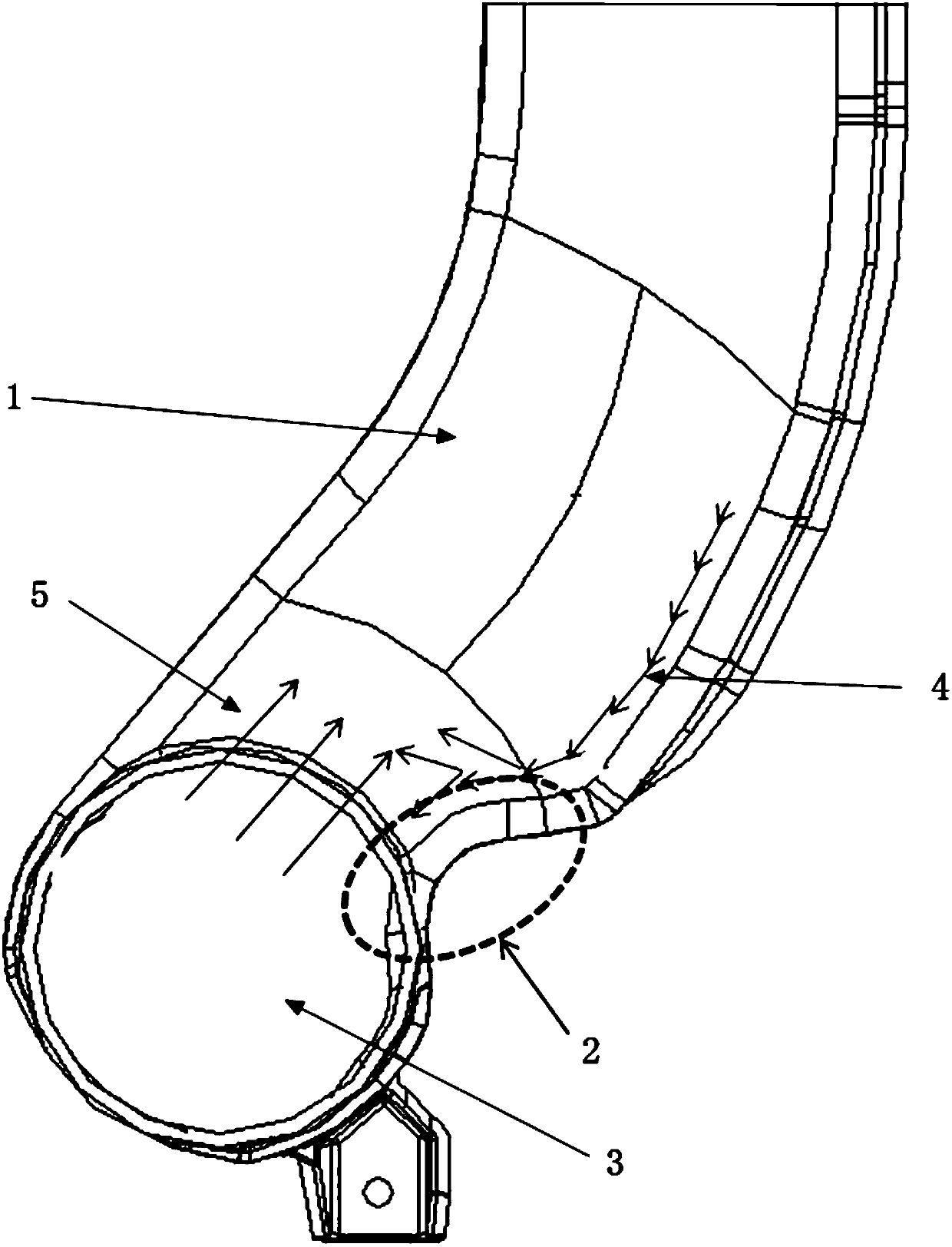

[0042] see figure 1 As shown, the present embodiment provides a condensing device, including a condensing pipe 1, the condensed water 4 water inlet is provided upstream of the condensed pipe 1, and the air inlet 3 is provided downstream, and the condensing pipe 1 is provided with a device for changing the flow direction of the condensed water 4 , increase the diversion structure in which the condensed water 4 is in heat exchange contact with the steam 5 .

[0043] In the above scheme, the heat exchange contact between the condensed water 4 and the steam 5 entering the condensing device from the air inlet 3 is increased by setting the diversion structure, so that the condensed water 4 participating in the heat exchange increases, and the conversion of the steam 5 into the condensed water 4 is improved. The power of the condensing pipe 1 is set by setting the diversion structure so that after the steam 5 enters the condensing pipe 1 of the condenser, the flow velocity becomes fa...

Embodiment 2

[0066] Embodiment 2 is different from the diversion structure of the condensing device of Embodiment 1. In Embodiment 2, the diversion structure includes a recessed groove arranged on the inner wall surface of the condensation pipe 1. The bottom of the groove is connected with an air injection port, and the air injection port is connected with a Air injection device, during the condensation process, after the condensed water 4 flows down from the upstream, part of the condensed water 4 will be deposited in the groove, and the air injection device will be activated to spray the condensed water 4 deposited in the groove to the entire interior of the chamber , thereby increasing the contact heat exchange area between the condensed water 4 and the steam 5, which also serves the purpose of improving the condensation efficiency. The gas injection port is arranged at the lowest point of the groove, which is formed by the inner wall of the condensation pipe 1 protruding radially outwar...

Embodiment 3

[0068]The third embodiment provides a clothes processing device using the condensing device in the first embodiment above. The clothes processing device includes a drying chamber and the condensing device. The drying chamber forms a circulating drying air path. The condensing device includes a condensing pipe 1, and the inner wall of the condensing pipe 1 near the air inlet 3 is provided with a protrusion 2, forming an arc-shaped bend, so that after the steam 5 enters the air inlet 3, the high-speed condensed water 4 flows through the arc Fluid separation occurs when resistance is encountered in a curved bend, and the condensed water 4 involved in heat exchange increases, thereby improving the heat exchange efficiency between the steam 5 and the condensed water 4 . The clothing processing equipment has a good condensation effect, and the amount of lint and impurities entering the condensing device and the drying air duct is greatly reduced, which can prevent the blockage of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com