Skid-mounted wellhead injection device and method for gel dispersoid soft body heterogeneous composite oil displacement system, and application

A jelly dispersion and composite oil displacement technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to meet the requirements of fluid mixing and injection in the control and flooding system, and meet the requirements of regulation and displacement. The effect of flooding operation requirements, improving on-site safety injection, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

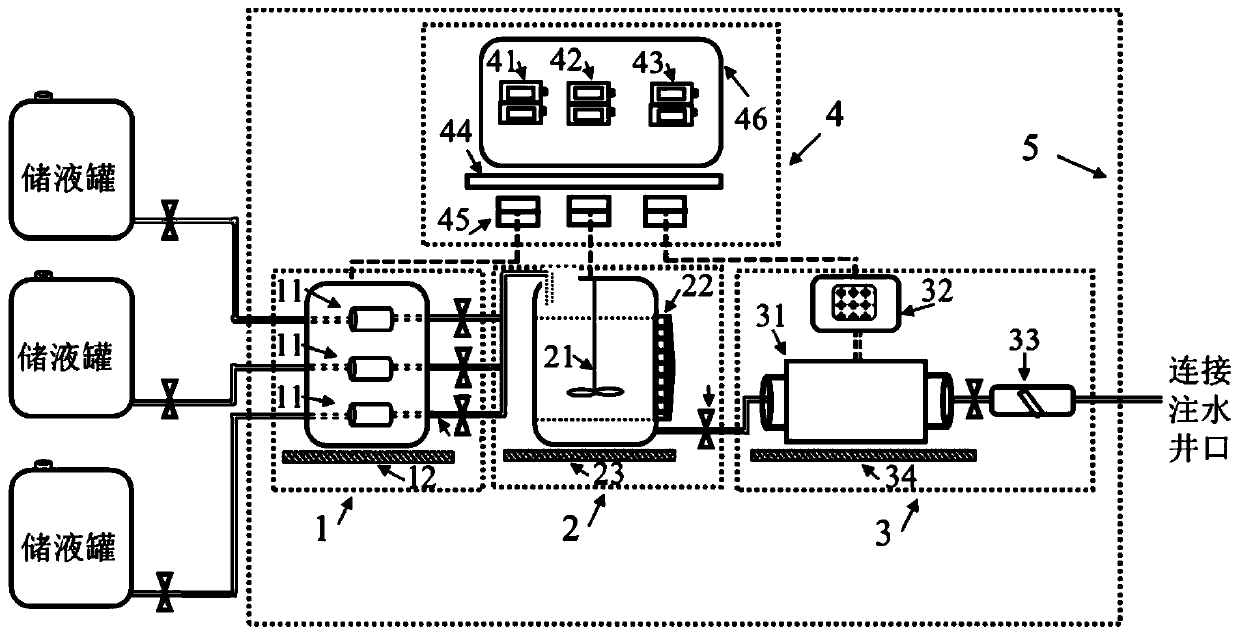

Image

Examples

Embodiment 1

[0061] Taking the X1 well of Xia 52 Block of Linpan Oil Production Plant of Shengli Oilfield as an example, the single-component gel dispersion flooding technology is implemented. The daily water injection volume of this well is 24 cubic meters per day (1.0 cubic meters per hour). After water injection, the gel dispersion The mass concentration of jelly dispersion in the body flooding system is 1.0%, utilizes the device of the present invention to carry out the wellhead injection method of jelly dispersion oil flooding system, comprises the following steps:

[0062] (1) The jelly dispersion stock solution tank is placed in the water injection workshop, and a pump of the pumping system is connected with the jelly dispersion stock solution tank by a hose;

[0063] (2) Turn on the pumping system, set the pumping speed of the pumping system pump to be 0.015 cubic meters per hour, close the other pumps, and extract the jelly dispersion into the stirring and mixing system;

[0064] ...

Embodiment 2

[0067] Taking the X2 well of Xia 52 Block of Linpan Oil Production Plant of Shengli Oilfield as an example, the single-component gel dispersion flooding technology is implemented. The daily water injection volume of this well is 24 cubic meters per day (1.0 cubic meters per hour). After water injection, the gel dispersion The mass concentration of jelly dispersion in the body flooding system is 1.5%, utilizes the device of the present invention to carry out the wellhead injection method of jelly dispersion oil flooding system, comprises the following steps:

[0068] (1) The jelly dispersion stock solution tank is placed in the water injection workshop, and a pump of the pumping system is connected with the jelly dispersion stock solution tank by a hose;

[0069] (2) Turn on the pumping system, set the pumping speed of the pumping system pump to be 0.02 cubic meters per hour, turn off the other pumps, and extract the jelly dispersion into the stirring and mixing system;

[0070...

Embodiment 3

[0073] Taking Well A1, Fan 4 Unit, Daluhu Oilfield, Daluhu Oilfield, Shengli Oilfield Dongsheng Jinggong Petroleum Development Group Co., Ltd. as an example, the two-component jelly dispersion soft heterogeneous composite flooding technology was implemented. The daily water injection volume of this well is 24 cubic meters per day (1.0 square / hour), after water injection, the jelly dispersion mass concentration is 1.0% in the multi-component of the gel dispersion soft heterogeneous composite oil displacement system, and the oil displacement agent A mass concentration is 0.3%, utilizes the present invention The device performs the wellhead injection method of the jelly dispersion soft heterogeneous composite flooding system, comprising the following steps:

[0074] (1) Place the multi-component jelly dispersion stock solution tank and oil displacement agent A stock solution tank of the gel dispersion soft heterogeneous composite oil displacement system in the water injection work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com