a ball valve

A technology for ball valves and valve sleeves, applied to valve details, valve devices, multi-way valves, etc., can solve problems such as time-consuming and energy-consuming, potential safety hazards, and long assembly time, and achieve convenient disassembly, assembly, and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

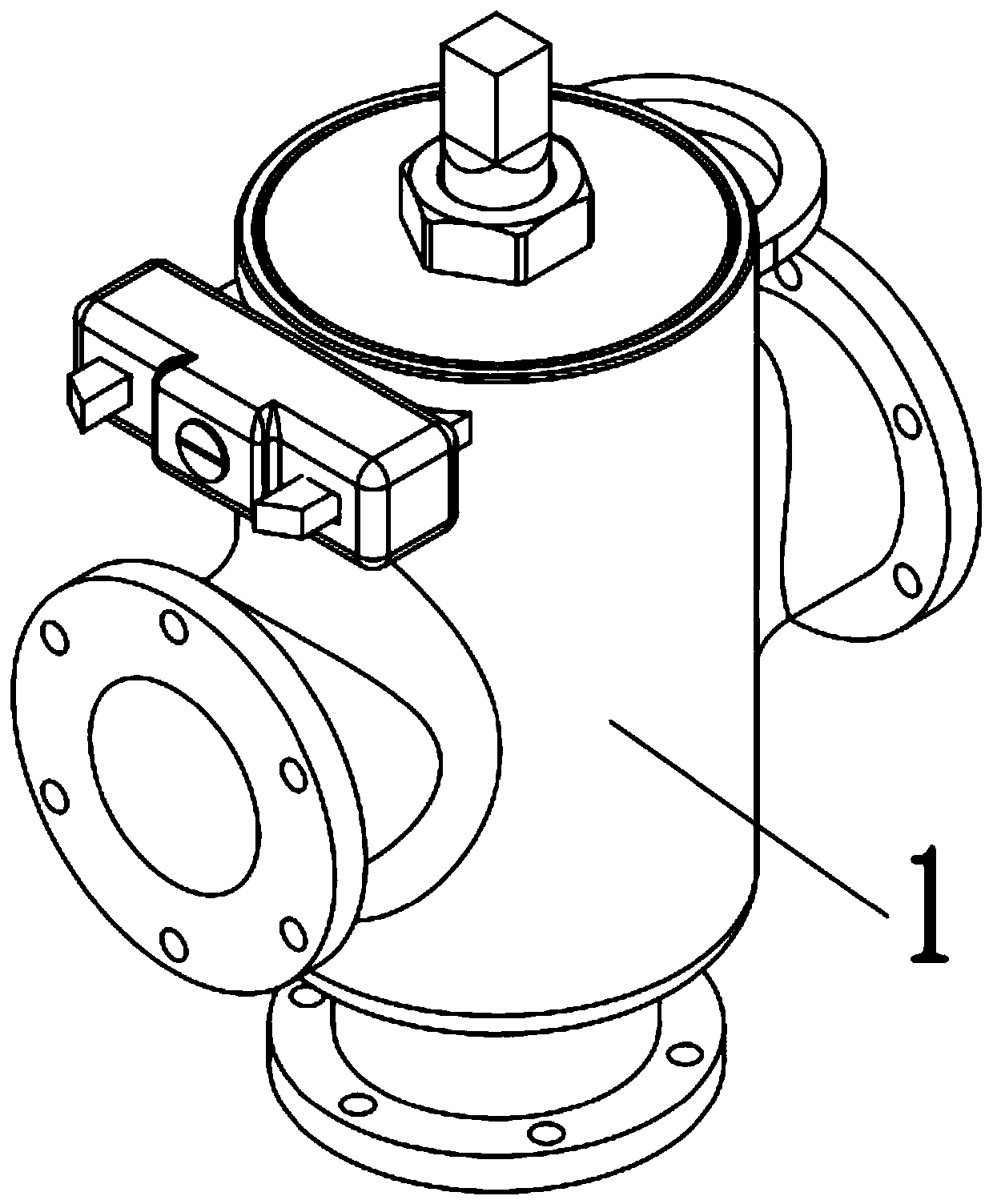

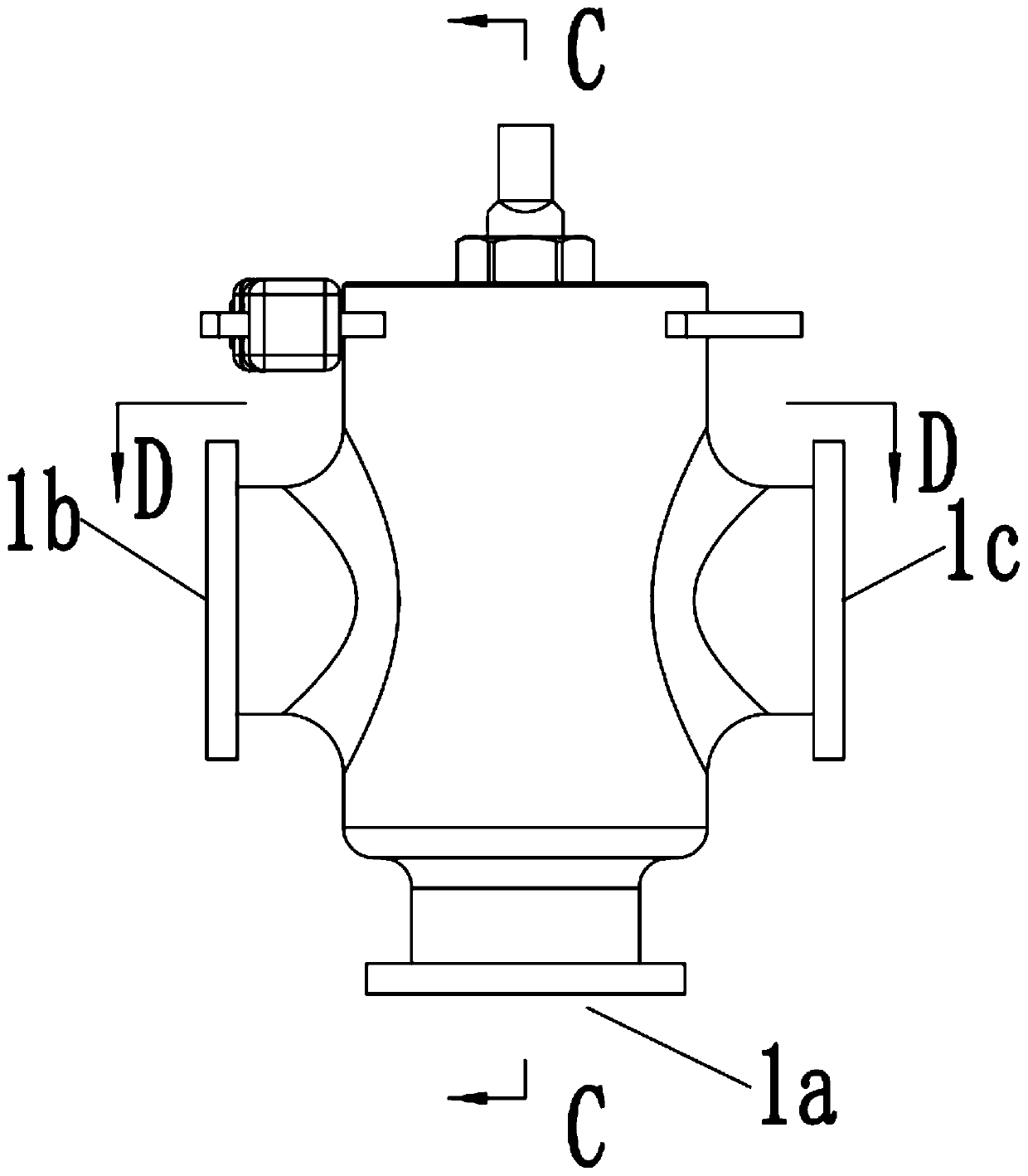

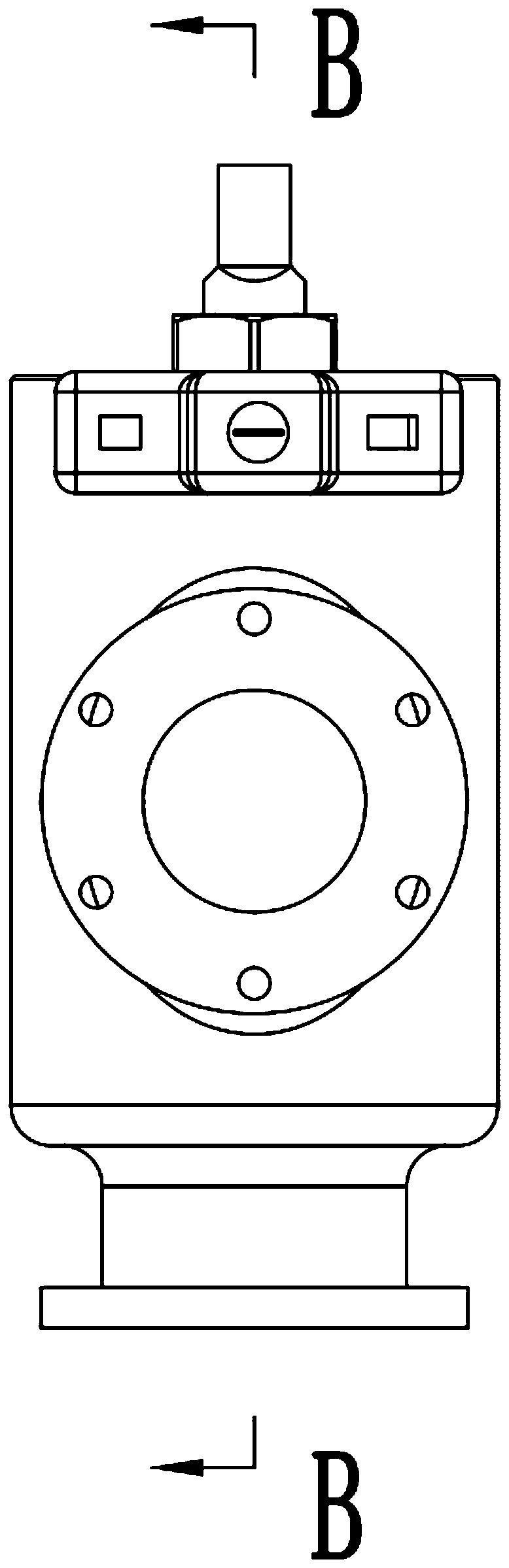

[0027] see Figure 1-12 As shown, a ball valve includes a top cover 9 and a valve housing 1 with an opening at the upper end, the lower end of the valve housing 1 is provided with a first channel 1a, the side of the valve housing 1 is provided with a center located in the same horizontal plane, and The coaxial second channel 1b and the third channel 1c; the top cover 9 is arranged on the upper opening of the valve housing 1 through the U-shaped lock bar 7, and the opening of the U-shaped lock bar 7 is provided with a lock block 8; The side of the valve housing 1 is provided with two first insertion holes 101 for the insertion of the U-shaped lock bar 7 side by side near its upper opening, and the top cover 9 is provided with two side by side for the U-shaped lock bar 7. The second insertion hole 9a for insertion. The valve housing 1 is provided with a valve core assembly installed on the top cover 8 at the first channel 1a; the valve core assembly is used to control the on-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com