Hot casting measuring method and device based on compressed sensing algorithm

A technology of compressed sensing and measurement device, which is applied in measurement device, optical device, instrument, etc., and can solve problems such as inability to obtain images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

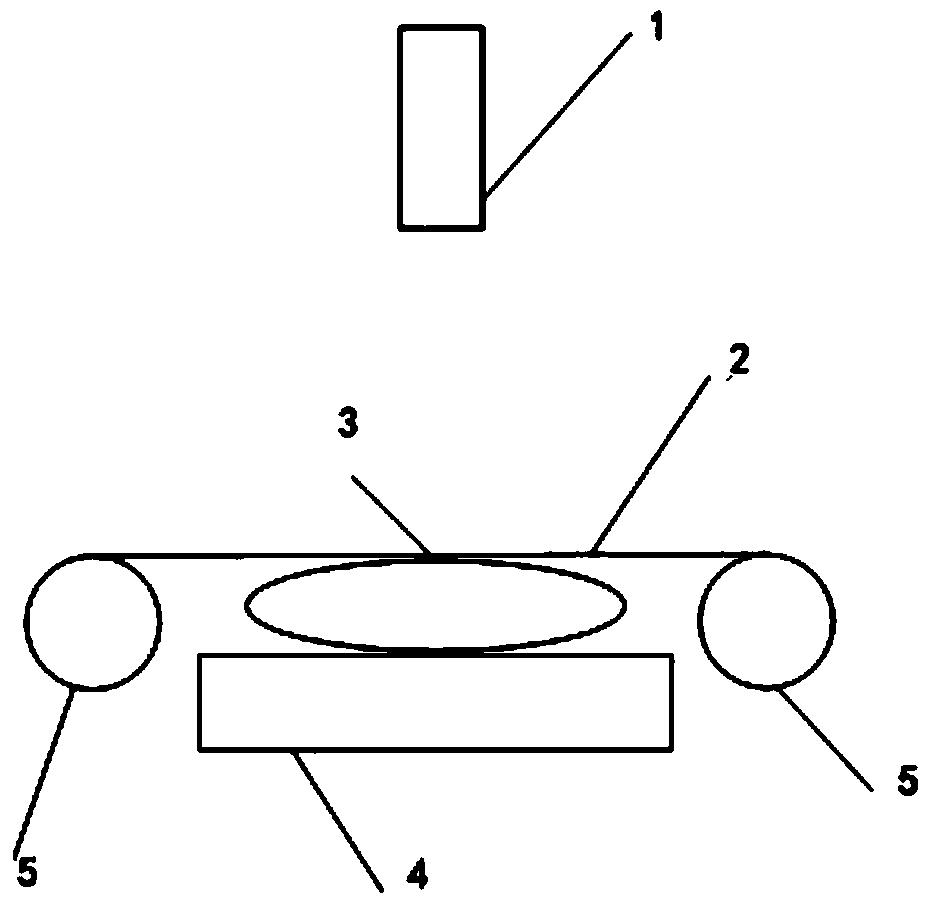

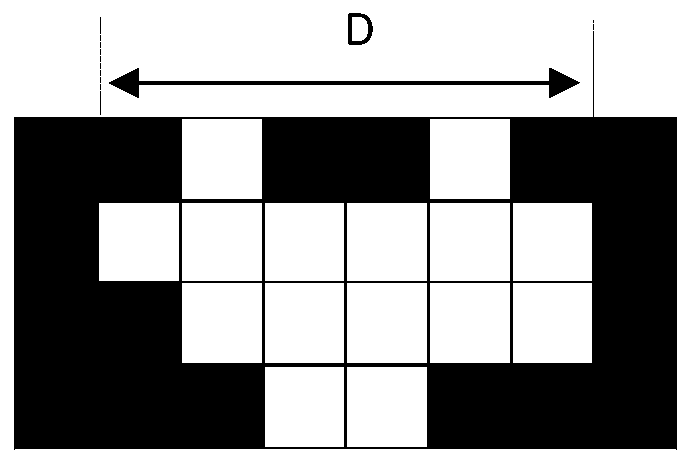

[0027] Such as Figure 1-Figure 3 As shown, this embodiment includes a photoelectric sensor 1, a placement platform 4 and a grid baffle, and the grid baffle is made of asbestos net or other high temperature resistant materials. The high temperature resistance refers to the temperature resistance above 800 degrees. The structure of the asbestos net 2 is a square grid structure, the size of each grid is d, 50% of the grids are fixed with shading baffles, and the distribution of shading baffles is distributed according to the random vector generated by the computer, which is generated by the computer and storage. The light emitted by the hot casting 3 to be tested cannot pass through the shading baffle, but can only pass through the grid without the shading baffle on the asbestos mesh 2 . In order to ensure the measurement accuracy of the device, the size of the square grid should be smaller than the measurement accuracy requirements. At the same time, the distance between the...

Embodiment 2

[0052] Such as figure 1 figure 2 and Figure 4 As shown, this embodiment includes a photoelectric sensor 1, a placement table 4, a baffle 6 and a grid baffle, and the baffle 6 and the grid baffle are made of asbestos net or other high temperature resistant materials. The high temperature resistance refers to the temperature resistance above 800 degrees. The baffle plate 6 is fixed on the placement platform 4, and the left end of the hot casting 3 is fixed on the placement platform 4. The hot casting 3 is placed on the placement table 4, and both sides of the placement table 4 are fixed with support motors 5, and the asbestos net 2 is connected between the support motors 5 on both sides of the placement table 4, and the rotation of the support motor 5 drives the asbestos net 2 on both sides. Two-way movement between two supporting motors 5, the photoelectric sensor 1 is fixed on the top of the asbestos net 2, the photoelectric sensor 1 can receive the light source informati...

Embodiment 3

[0077] Such as figure 2 , image 3 , Figure 5 and Figure 6 As shown, this embodiment includes a photoelectric sensor 1, a lower transmission device 8, an upper transmission device 7 and a grid baffle, and the grid baffle is made of asbestos net or other high temperature resistant materials. The high temperature resistance refers to the temperature resistance above 800 degrees. The structure of the asbestos net 2 is a square grid structure, the size of each grid is d, 50% of the grids are fixed with shading baffles, and the distribution of shading baffles is distributed according to the random vector generated by the computer, which is generated by the computer and storage. The light emitted by the hot casting 3 to be tested cannot pass through the shading baffle, but can only pass through the grid without the shading baffle on the asbestos mesh 2 . In order to ensure the measurement accuracy of the device, the size of the square grid should be smaller than the measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com