Test chamber capable of simulating mechanical property of test piece under freezing and thawing temperature load

A test box and test piece technology, applied in the field of mechanical performance test, can solve problems such as inability to carry out real-time, engineering practical application errors, and inaccurate test results, so as to improve efficiency, convenience, and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

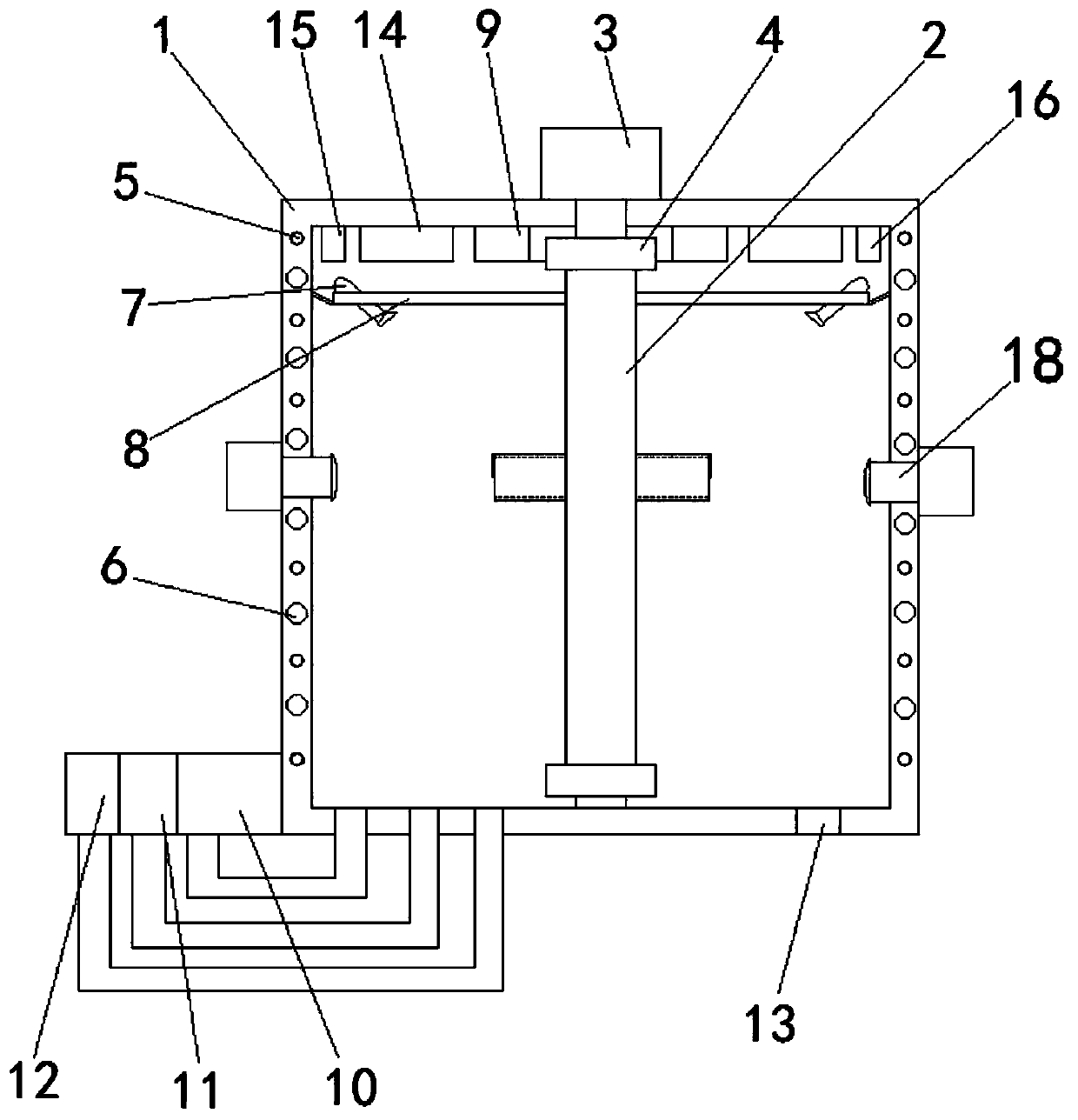

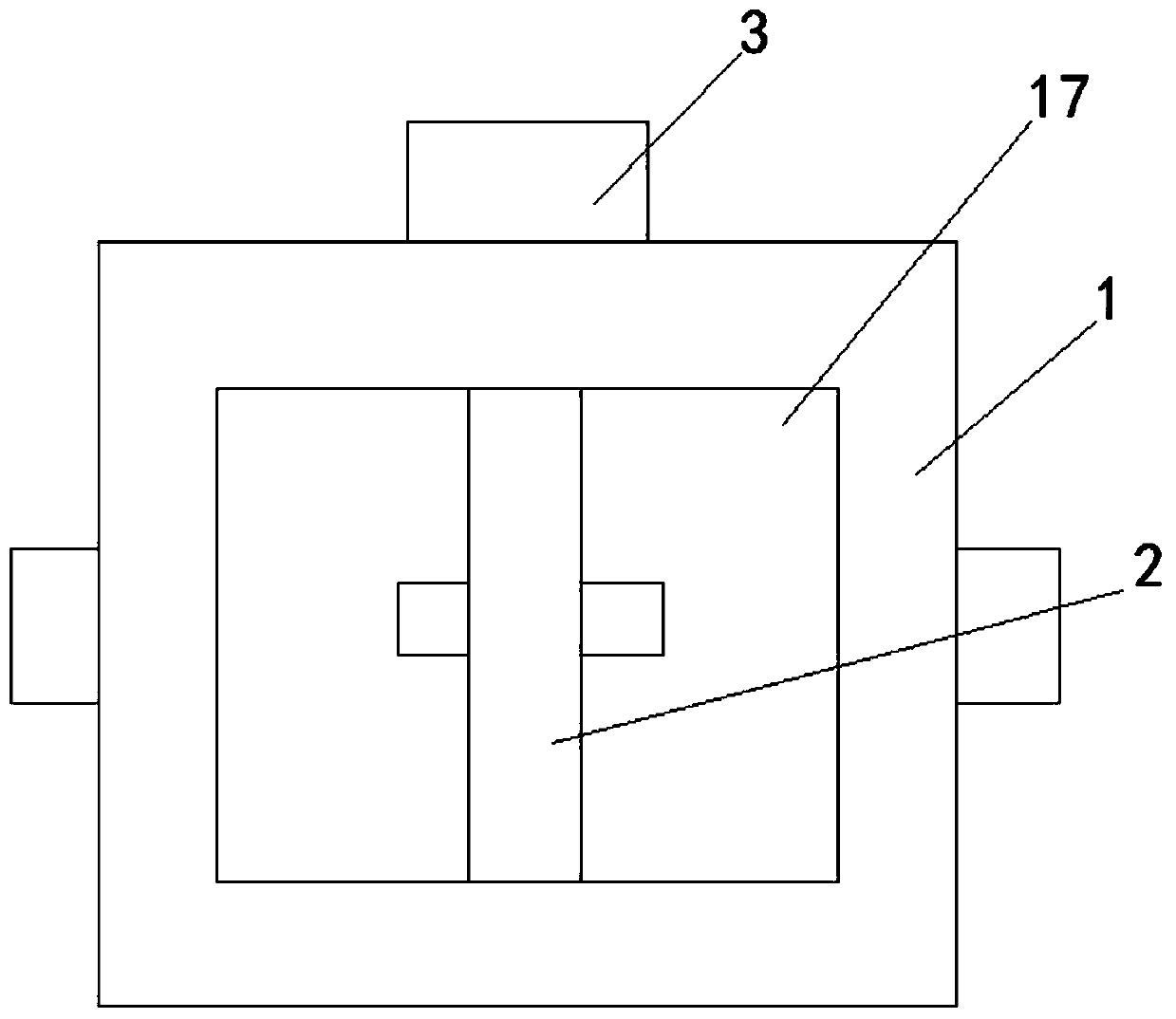

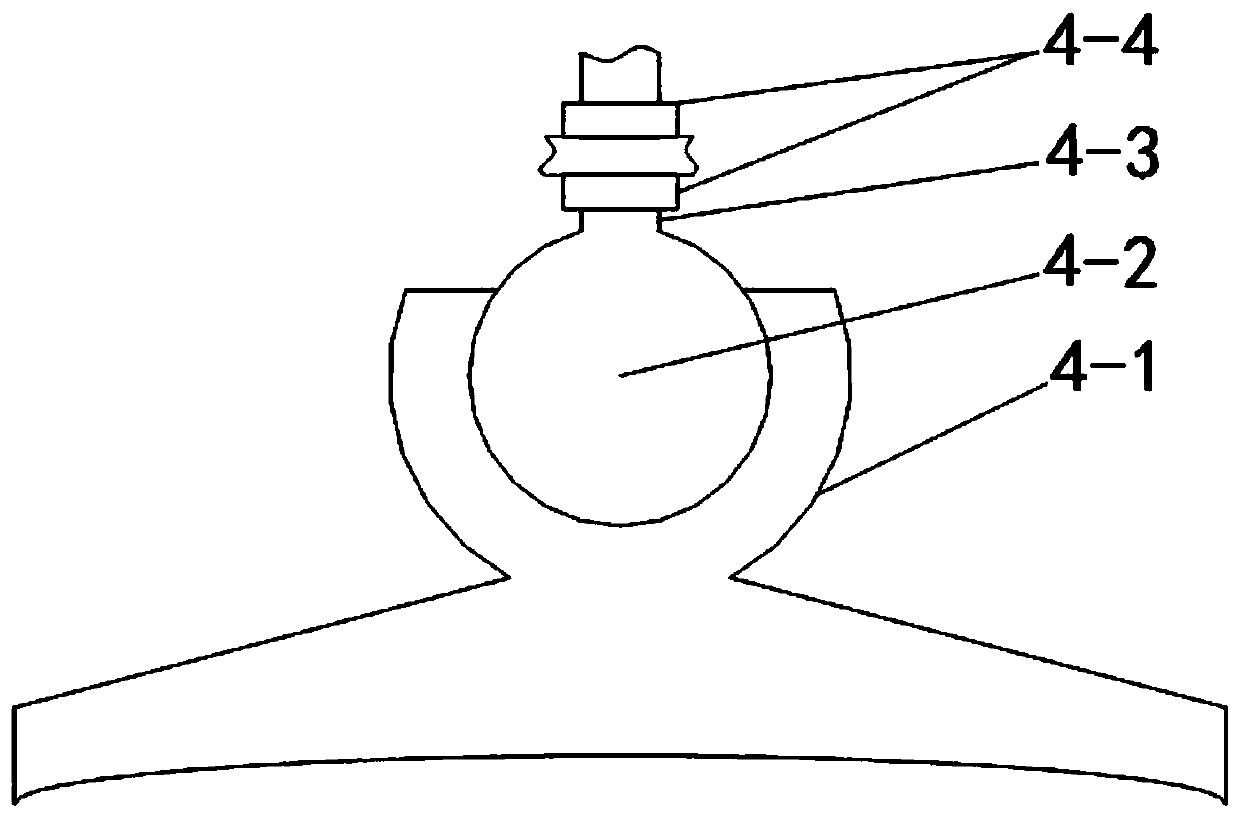

[0037] In this example, if figure 1 Shown, a kind of test chamber that can simulate the mechanical performance of the test piece under the freeze-thaw temperature includes a box body 1, and the test chamber includes a temperature control system, a stress loading system and an environment simulation system for simulating a real environment; the temperature The control system includes a refrigeration device and a heating device, both of which are located on the inner wall of the box body 1; the stress loading system is located on the top of the box body 1 and the stress loading system includes a stress loading device 3 and a fixed end of the test piece 4. The stress loading device 3 is located outside the top of the box body 1 , and the fixed end 4 of the specimen is fixed to the stress loading device 3 and extends to the inside of the box body 1 .

[0038] When implementing the test box proposed in Example 1, the temperature control system controls the inside of the box body 1 ...

Embodiment 2

[0040] In this example, if figure 1 Shown, a kind of test chamber that can simulate the mechanical performance of the test piece under the freeze-thaw temperature includes a box body 1, and the test chamber includes a temperature control system, a stress loading system and an environment simulation system for simulating a real environment; the temperature The control system includes a refrigeration device and a heating device, both of which are located on the inner wall of the box body 1; the stress loading system is located on the top of the box body 1 and the stress loading system includes a stress loading device 3 and a fixed end of the test piece 4. The stress loading device 3 is located outside the top of the box body 1 , and the fixed end 4 of the specimen is fixed to the stress loading device 3 and extends to the inside of the box body 1 .

[0041] The environment simulation system includes a humidity control device, an environment control device 12, a rainfall simulati...

Embodiment 3

[0045] In embodiment 3, the test chamber in embodiment 3 is improved on the basis of embodiment 2, and described humidity control system comprises atomizing device 10 and blast drying device 11, and described atomizing device 10 and blast drying The devices 11 are all fixed on the bottom of the outside of the box body 1, and the atomization device 10 and the blast drying device 11 are respectively connected to the inside of the box body 1 through pipelines; the bottom of the box body 1 is provided with an air convection hole 13; Through the atomization device 10, the atomized liquid is passed into the inside of the box body 1, thereby increasing the humidity inside the box body 1, and the drying gas is passed into the inside of the box body 1 through the blast drying device 11, thereby reducing the humidity of the box body 1. The internal humidity, and then through the atomizing device 10 and the blast drying device 11, the humidity inside the box body 1 can be adjusted in a ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com