Thermal resistance correction method considering influence of thermocouple glue for IGBT aging experiment

An aging experiment, thermocouple technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as thermal resistance correction without explanation, and achieve the effect of simple and intuitive correction method, easy operation, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

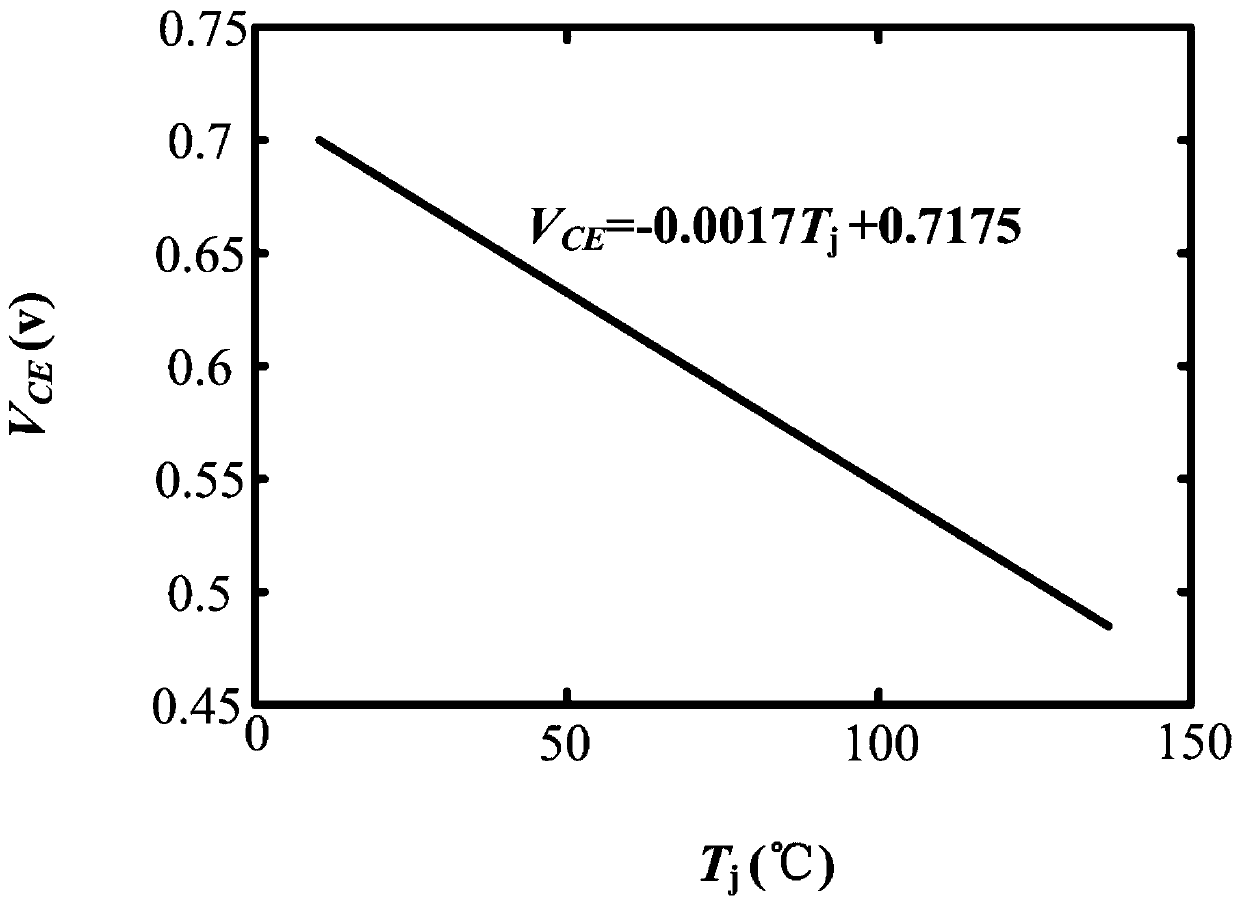

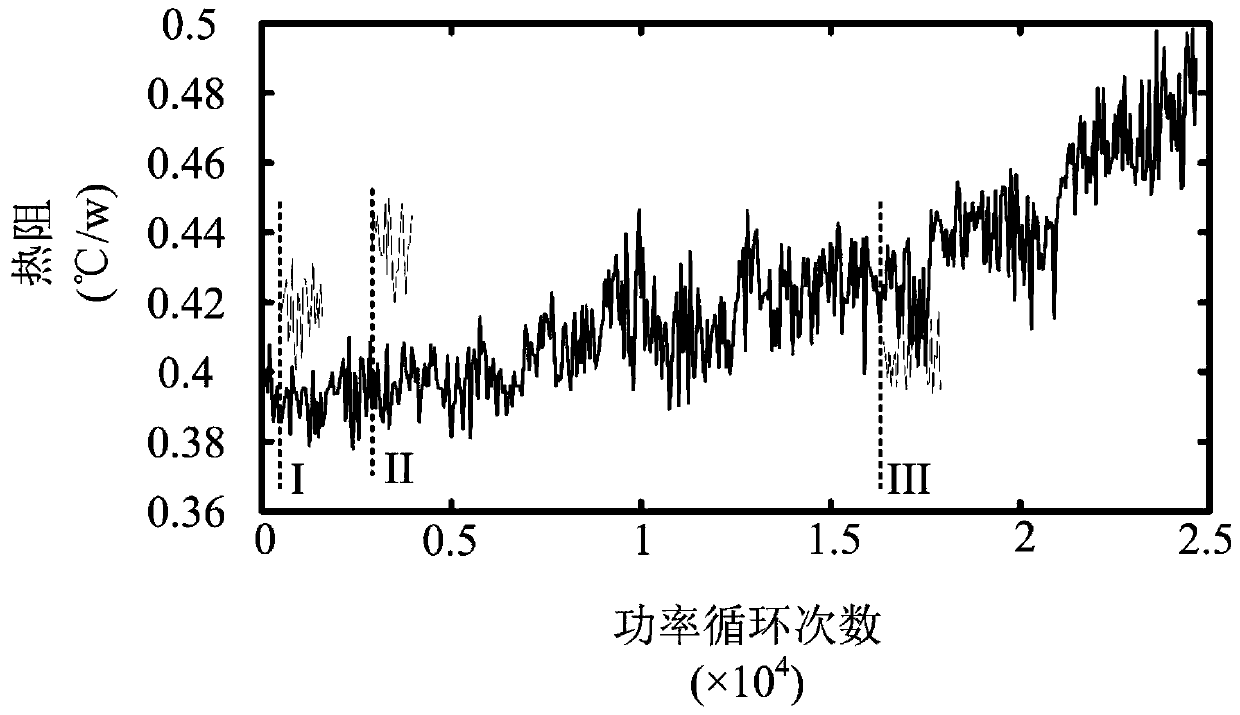

[0102] Example 1: The glue loosened during the 2853rd power cycle, so that the thermal resistance value R th(2853) Equal to the thermal resistance value R obtained in the 2852th power cycle th(2852) , and obtain the shell temperature correction ΔT needed for the subsequent power cycle c2853 , then the thermal resistance value R extracted by this power cycle th(2853) and the shell temperature correction ΔT required for subsequent power cycles c2853 They are:

[0103] R th(2853) =R th(2852) =0.4086

[0104] ΔT c2853 =(T j "-T j0 ”)-(T c2 "-T c0 ”)-R th(2852) P" = 2.607°C.

Embodiment 2

[0105] Example 2: n=5750. If the glue does not loosen during the 5750th power cycle, then proceed to the next step of judgment. In this embodiment 2, n=5750, k=2853, V CE0 "=0.6247V, the corresponding T j0 ”=54.56°C. T measured by thermocouple c0 ” = 42.87°C, V CE "=0.5061V, the corresponding T j ”=124.38°C. T measured by thermocouple c2 ” = 68.44°C, V CEL "=1.6982V, the corresponding P"=101.89W, ΔT c2853 = 2.607°C. That is, in the 2853th power cycle between the 1st power cycle and the 5750th power cycle, the glue loosened and the thickness of the glue after replacement increased, then the thermal resistance value extracted by the 5750th power cycle was:

[0106]

[0107] where ΔT c2853 Case temperature correction for the 2853rd power cycle.

Embodiment 3

[0108] Embodiment 3: n=19421, k=16359, V CE0 "=0.6162V, the corresponding T j0 ”=59.61℃. T is obtained by thermocouple measurement c0 " = 46.99°C; V CE "=0.4953V, the corresponding T j ”=130.69℃. Through the IGBT module case temperature T c2 ” = 72.68°C, V CEL "=1.7243V, the corresponding P"=103.46W, ΔT c16359 = 1.036°C. That is, in the 16359th power cycle between the 1st power cycle and the 19421st power cycle, the glue loosened and the thickness of the glue after replacement decreased, then the thermal resistance value R extracted from the 19421st power cycle th(19421) for:

[0109]

[0110] where ΔT c16359 Case temperature correction for the 16359th power cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com